Double lock type door and window handle assembly

A component and handle technology, which is applied in the field of anti-lock door and window handle components, can solve the problems of inconsistency, inconvenience in use, asymmetric appearance inside and outside, and achieve the effect of reasonable overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

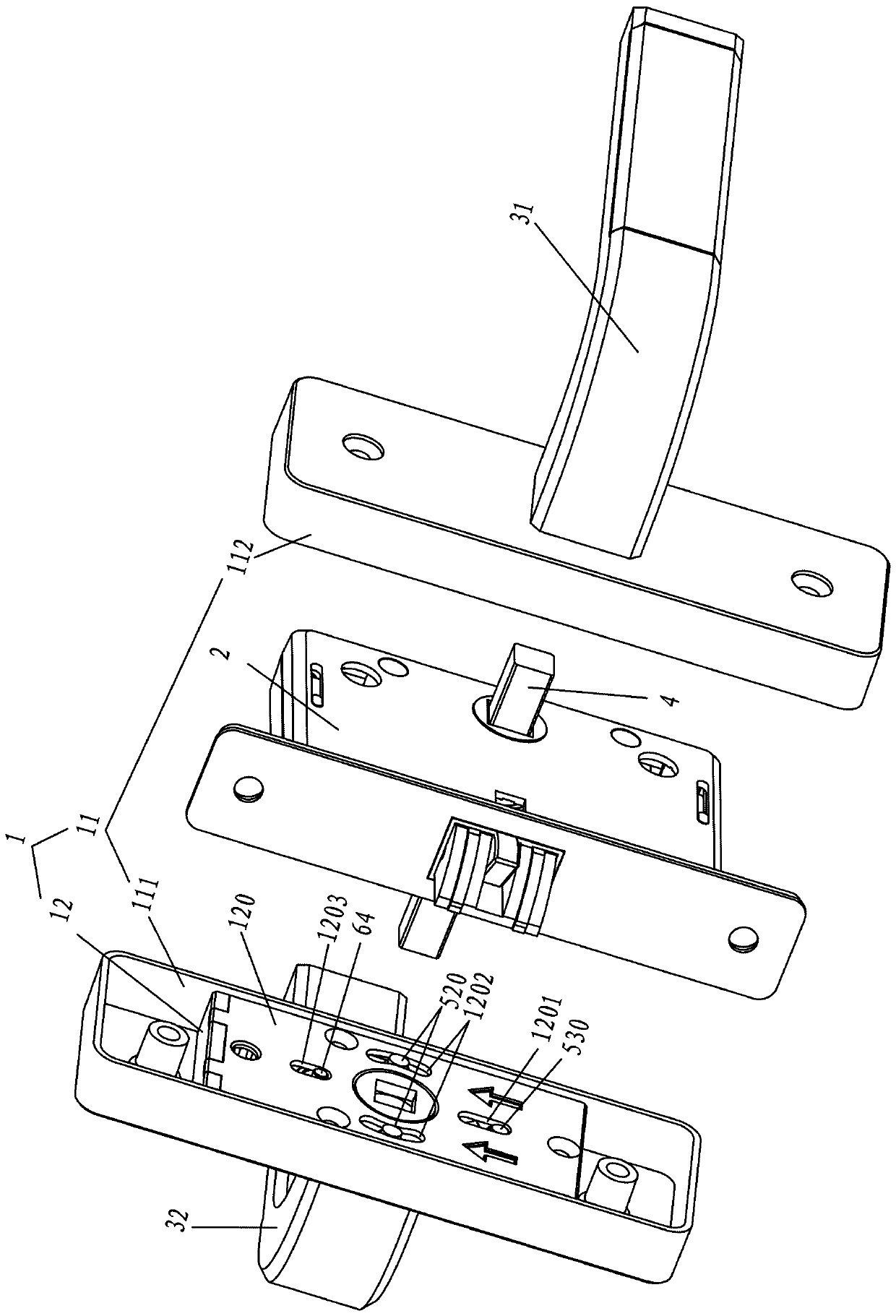

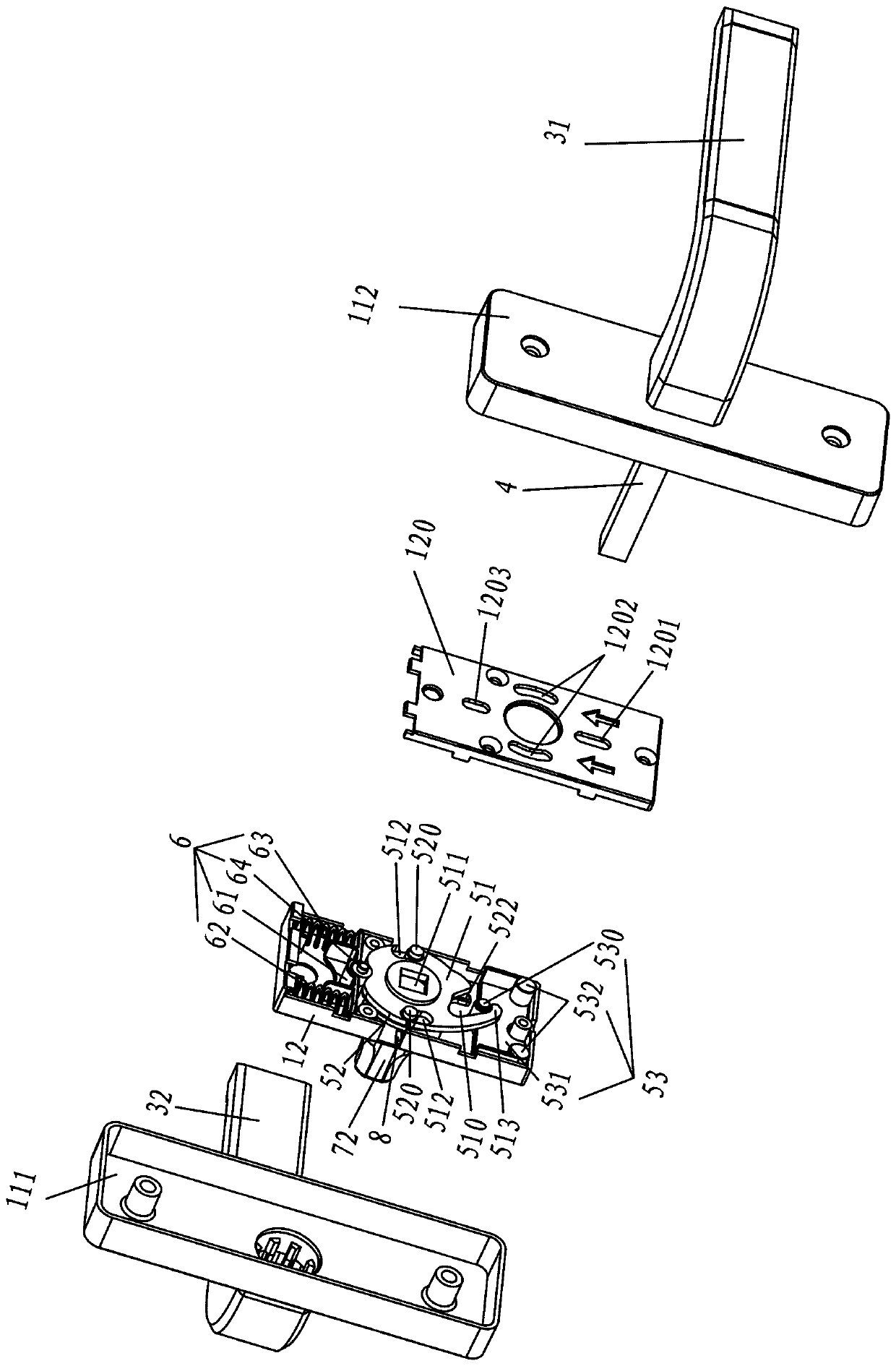

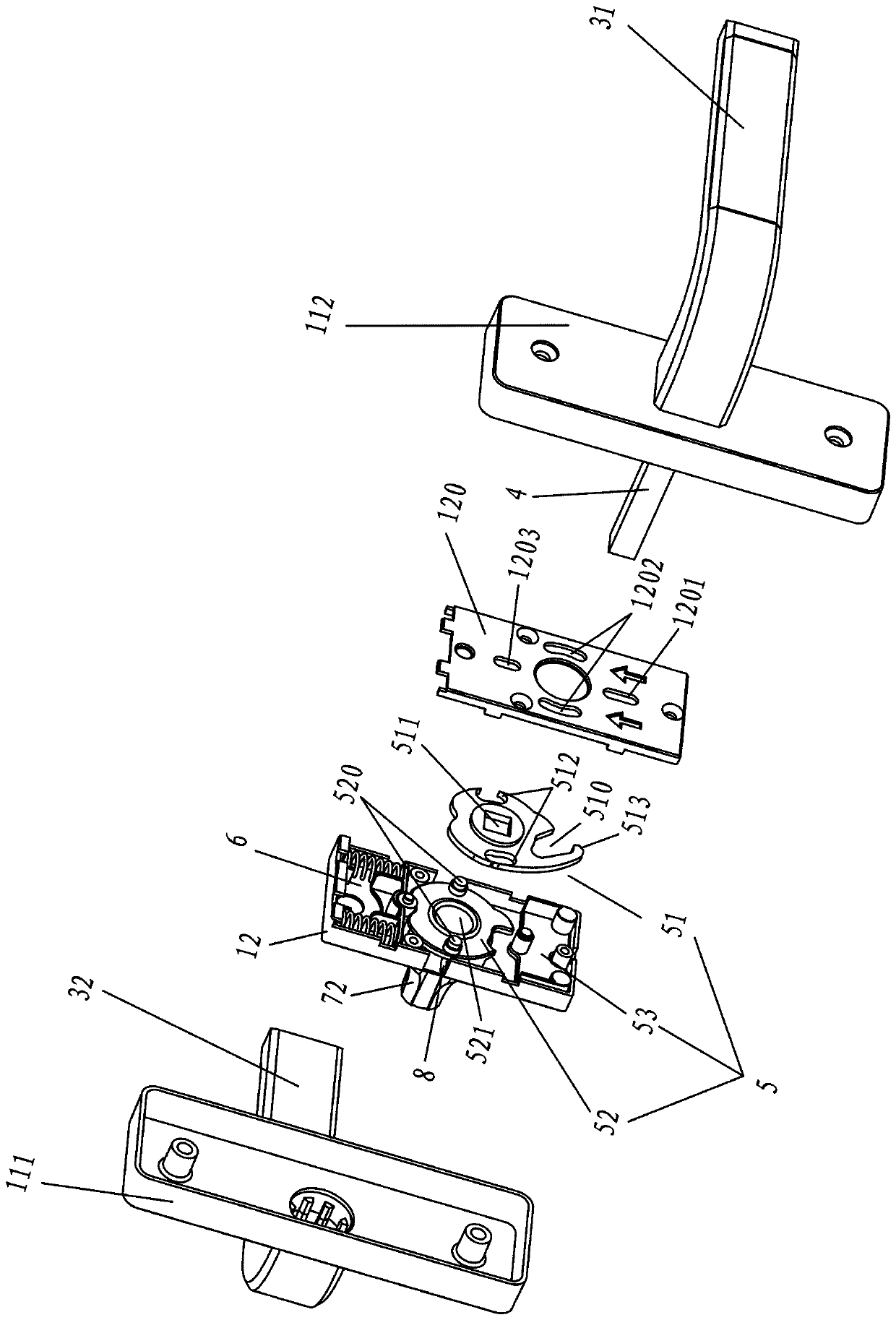

[0027] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

[0028] see Figure 1 to Figure 4 As shown, the anti-locking door and window handle assembly includes a housing 1, and an inner handle 31, a locking bar 4, an anti-locking assembly 5, an outer handle lock cylinder 72 and an outer handle 32 arranged on the housing 1, and the inner handle 31 is connected to the locking bar 4. The outer handle 32 is connected to the outer handle lock cylinder 72, the outer handle lock cylinder 72 is provided with a blocking member 52, the anti-lock assembly 5 includes an anti-lock member 51 and an anti-lock position device 53, and the anti-lock member 51 has an anti-lock hook groove 510, lock bar pushing hole 511 and blocking piece guide hole 512, blocking piece 52 is connected with outer handle lock core 72, and blocking piece 52 is also provided with derivation column 520, and the deriving column 520 of blocking piece 52 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com