Roof counter batten mounting structure

A technology for installing a structure and a water-sliding strip, which is applied to roof insulation materials, roofing, building structures, etc., can solve problems such as complex processes, and achieve the effects of convenient construction, simplified construction steps, and simple and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

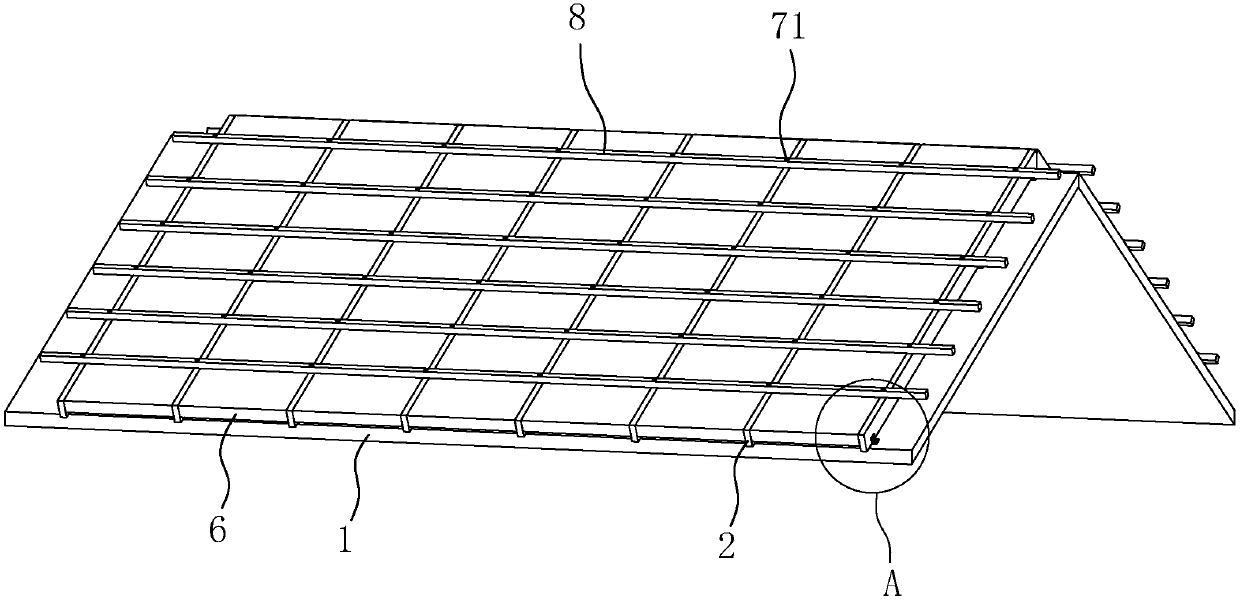

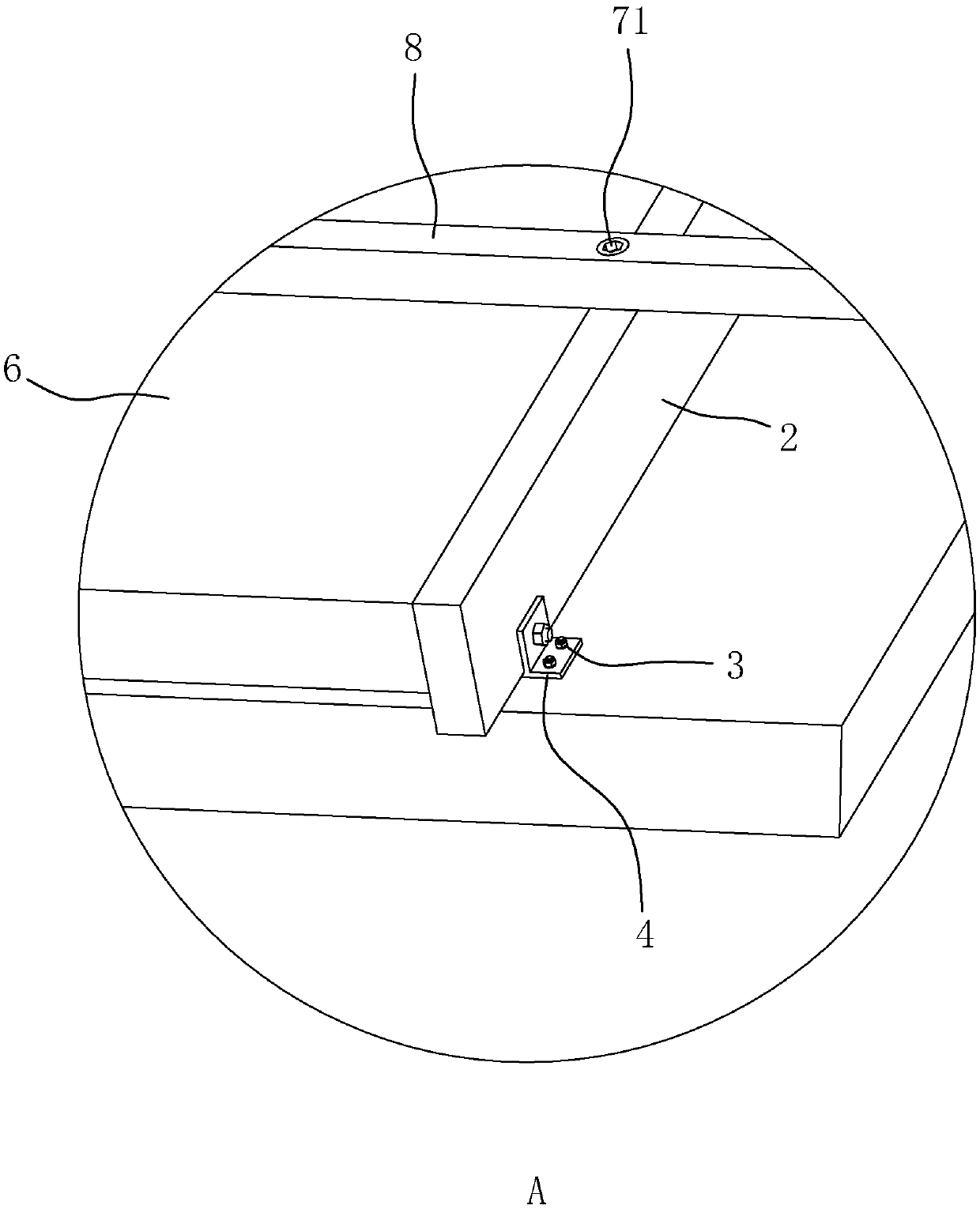

[0035] Embodiment 1: The installation structure of the roof along the water, such as figure 1 with figure 2 As shown, including the roof 1, the roof 1 is fixed with a number of longitudinal water strips 2 through several rows of fixing parts 4, and the interval between adjacent fixing parts 4 is about 1 meter, such as image 3 As shown, the fixing part 4 includes a base plate 41 fixed between the roof 1 and the roof 1 through the expansion bolt 3, a pair of vertical plates 42 are integrally formed on the base plate 41, and a card slot 43 for inserting the water strip 2 is formed between the vertical plates 42 . After inserting the downstream strip 2 into the card slot 43 , the vertical strip 2 is further tightened by pulling the bolts 5 through a pair of vertical plates 42 .

[0036] A thermal insulation board 6 is embedded between two adjacent downstream strips 2 , and the thermal insulation board 6 is clamped and fixed by the downstream strips 2 . The height of the water...

Embodiment 2

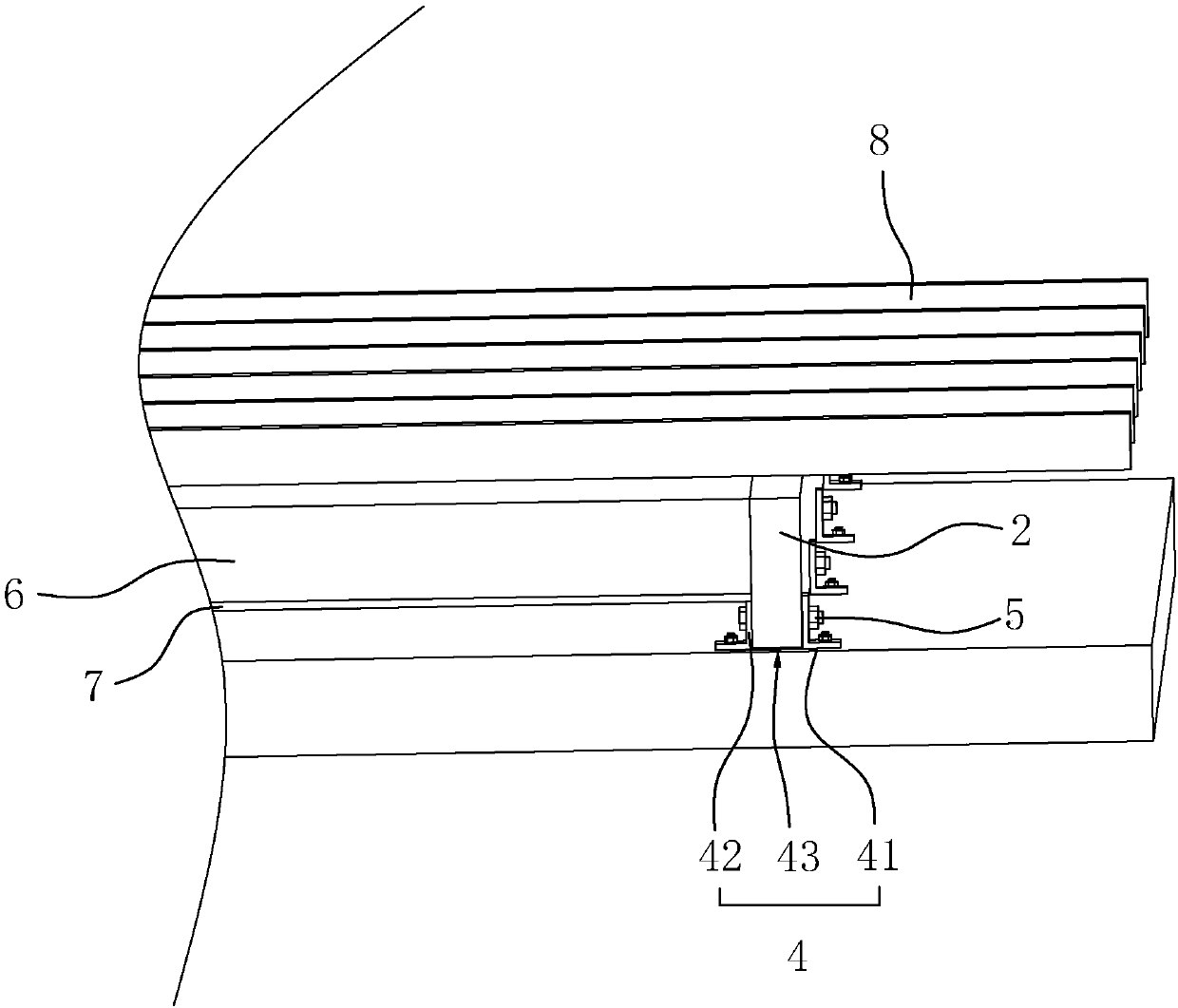

[0038] Embodiment 2: The installation structure of the roof along the water strips, the difference from Embodiment 1 is that, as Figure 4 with Figure 5 As shown, the length of the fixing part 4 is the same as the length of the water strip 2. After the water strip 2 is inserted, the two ends use the pull bolts 5 to pass through the fixing piece 4 to fix the water strip 2, and the middle part is fixed by a wood screw thread. The fixing part 4 has the same length as the smooth strip 2, which enhances the stability of clamping the smooth strip 2.

Embodiment 3

[0039] Embodiment 3: The installation structure of the roof along the water strip, the difference from Embodiment 2 is that, as Image 6 As shown, a pair of placement grooves 21 are provided in the middle of the adjacent downstream strips 2, and the insulation board 6 is clamped in the placement groove 21. The way of the insulation board 6 is more convenient to operate than being directly embedded between the downstream boards. Easy to install and fix.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com