A Constant Tension Device for Large Opening Model Tests of River-sea Direct Ships

A model test, large opening technology, applied in measurement devices, hydrodynamic tests, ship construction, etc., can solve problems such as the influence of failure mode, the pressure that cannot be simulated, the influence of the accuracy of experimental results, etc., to improve the accuracy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

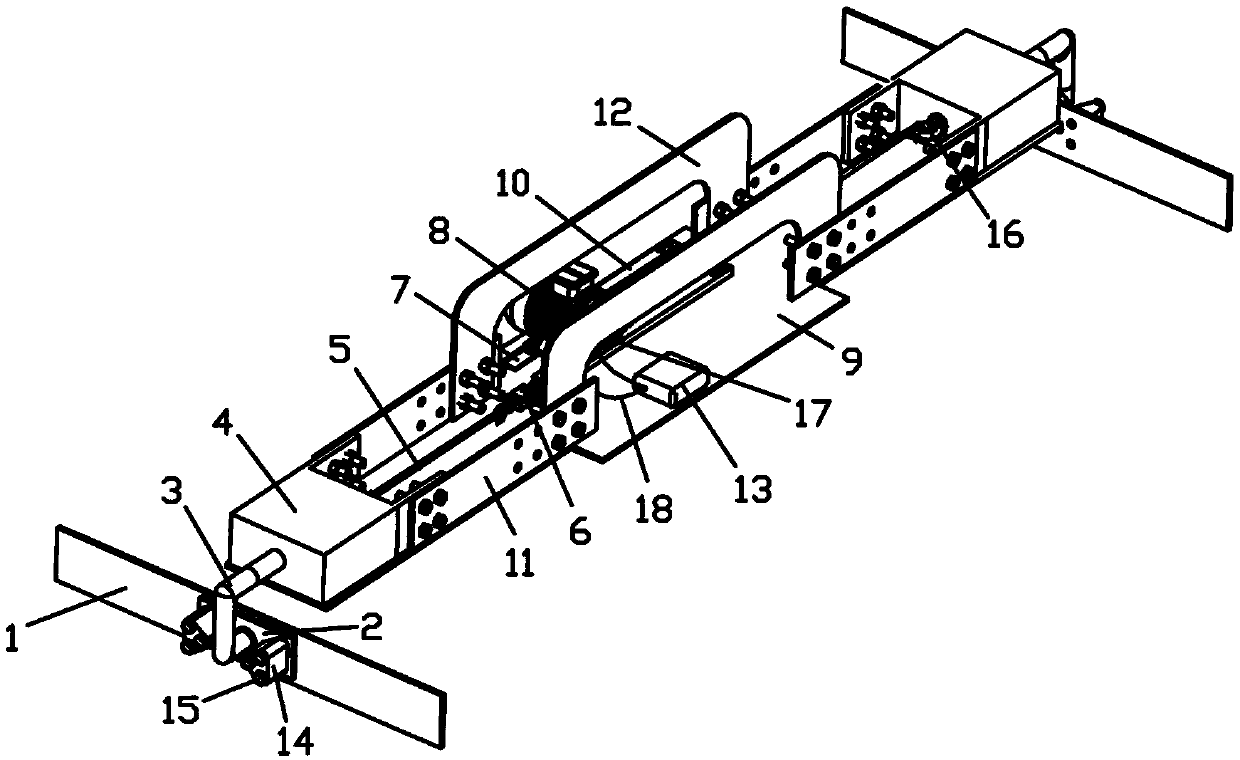

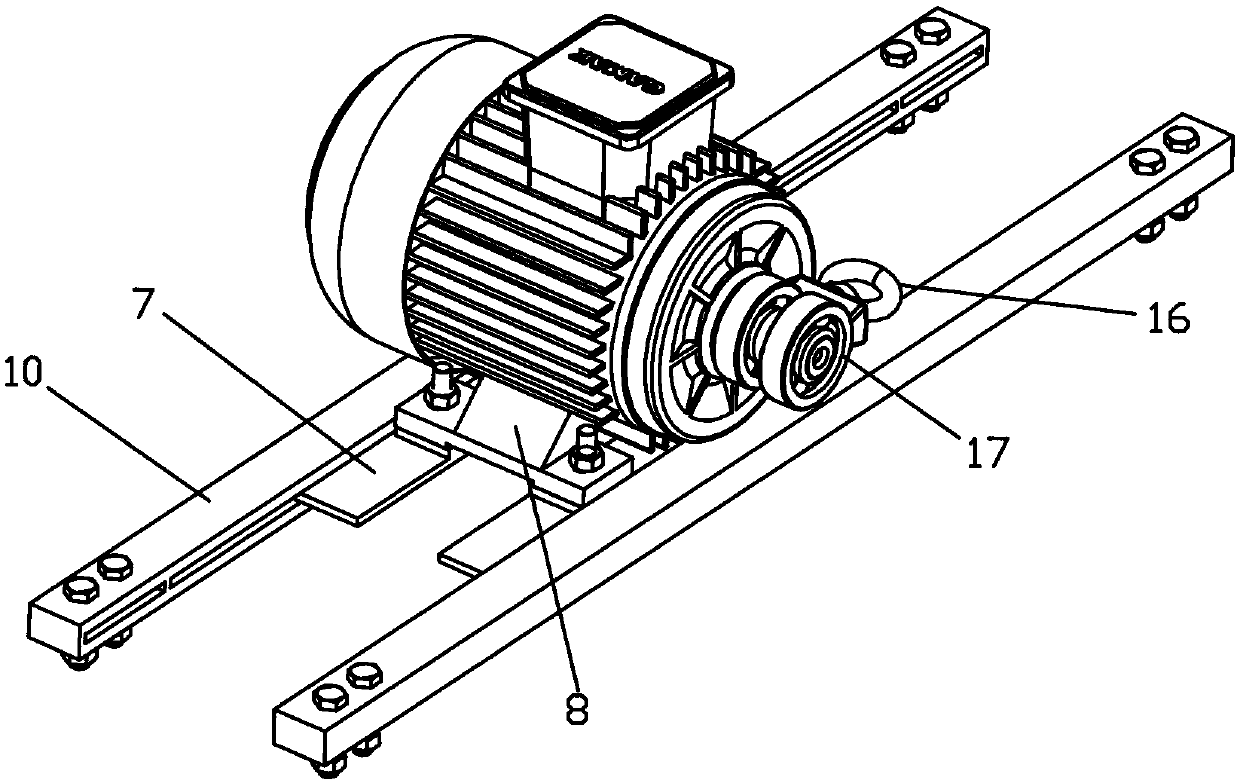

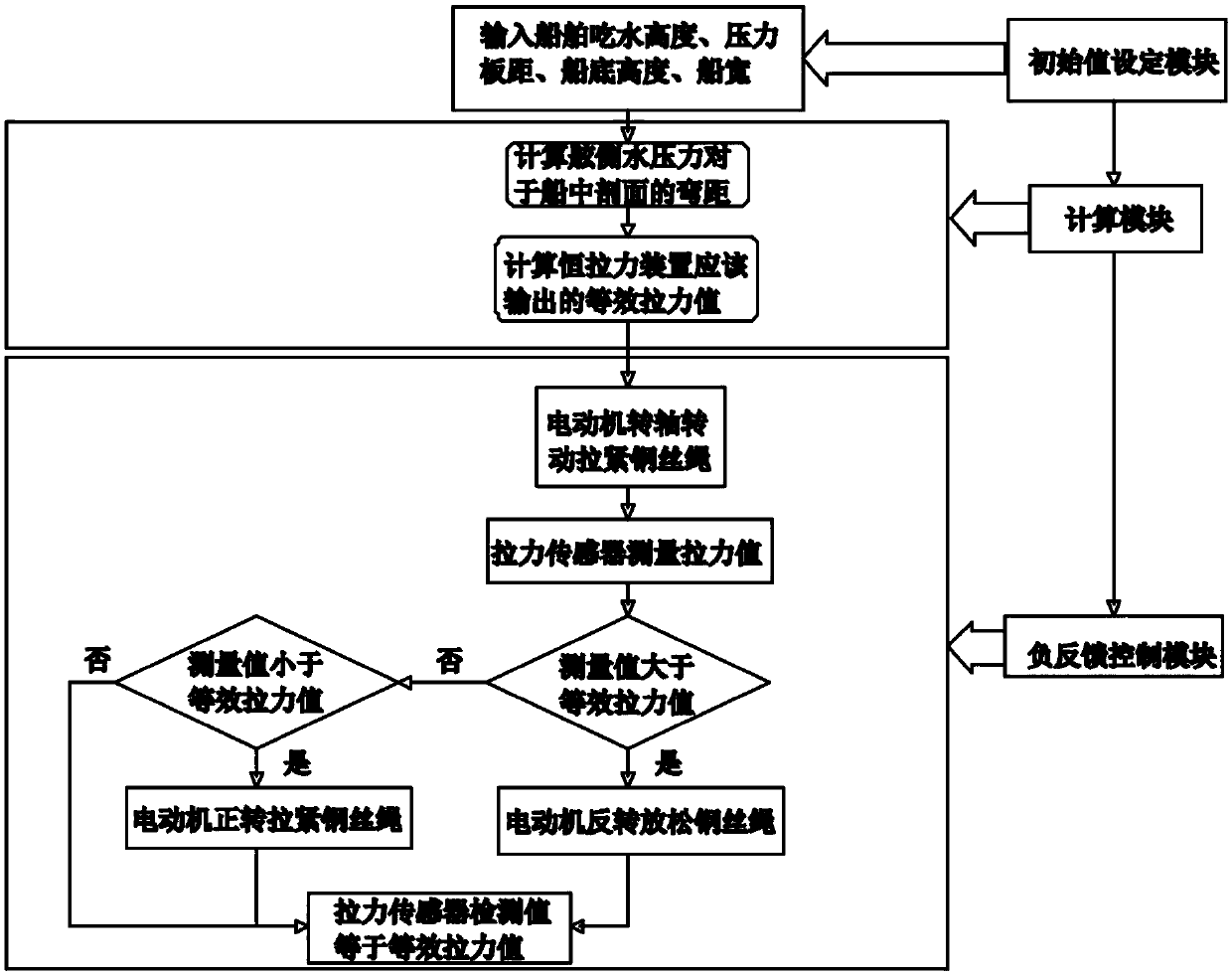

[0027] Such as figure 1 As shown, a kind of constant tension device used in the large opening model test of the river-sea direct ship according to the present invention includes a pressure plate 1, a transition panel 2, a sliding loading plate for applying equivalent side water pressure to the side plate of the model ship Axis 3, loading shaft sliding groove 4, steel wire rope 5, tension sensor 6, motor sliding plate 7, motor 8, support platform 9, motor chute 10, rectangular connecting plate 11, U-shaped connecting plate 12, controller 13, tension balance Device 17, signal line 18, pressure plate 1 and transition panel 2 are fixedly connected, one end of sliding loading shaft 3 is fixed on transition panel 2, the other end of sliding loading shaft 3 is limited on loading shaft sliding groove 4, and one end of steel wire rope 5 is con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com