High-speed beam carrier

A beam-carrying gun car, high-speed technology, applied in the direction of article transport vehicles, vehicles used for freight, vehicles used to carry long goods, etc., can solve the problems of passability, ease of use, poor durability, tire adhesion, etc. Poor road performance, local stress concentration of the frame, etc., to achieve the effects of good anti-overturning stability, large load capacity and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with embodiment the present invention will be further described, but the present invention is not limited to these examples, under the premise of departing from the gist of the present invention, any improvement made falls within the protection scope of the present invention.

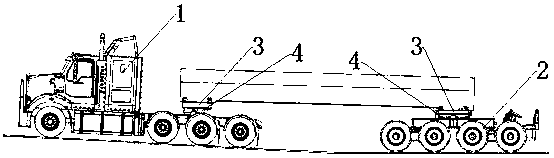

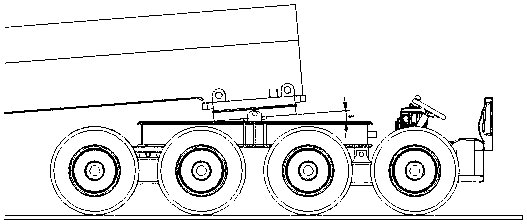

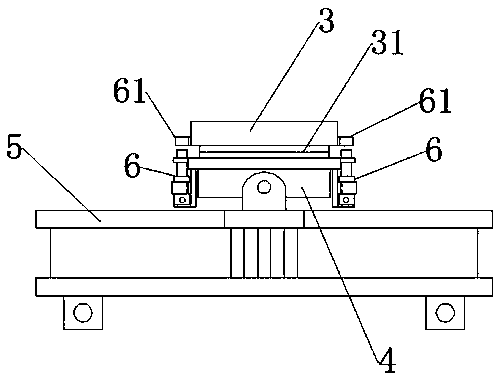

[0019] As shown in the figure, a high-speed beam-carrying artillery vehicle according to the present invention includes a driving vehicle 1 and a tractor 2, and the driving vehicle 1 and the tractor 2 all include a driver's seat, a vehicle frame 5, an axle, Wheels and auxiliary tilting carrier, the auxiliary tilting carrier includes a pitching frame 4 at the bottom and a bearing turntable frame 3 at the top, the bottom of the pitching frame 4 is fixed on the vehicle frame 5 through hinge parts, The hinged part is provided with a rotating shaft, and the rotating shaft is parallel to the vehicle axle. The bearing turntable frame 4 includes a rectangular bearing frame and a rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com