Laser welding method and laser welding device

A laser welding, laser technology, applied in laser welding equipment, welding equipment, conductors and other directions, can solve the problem of low laser absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

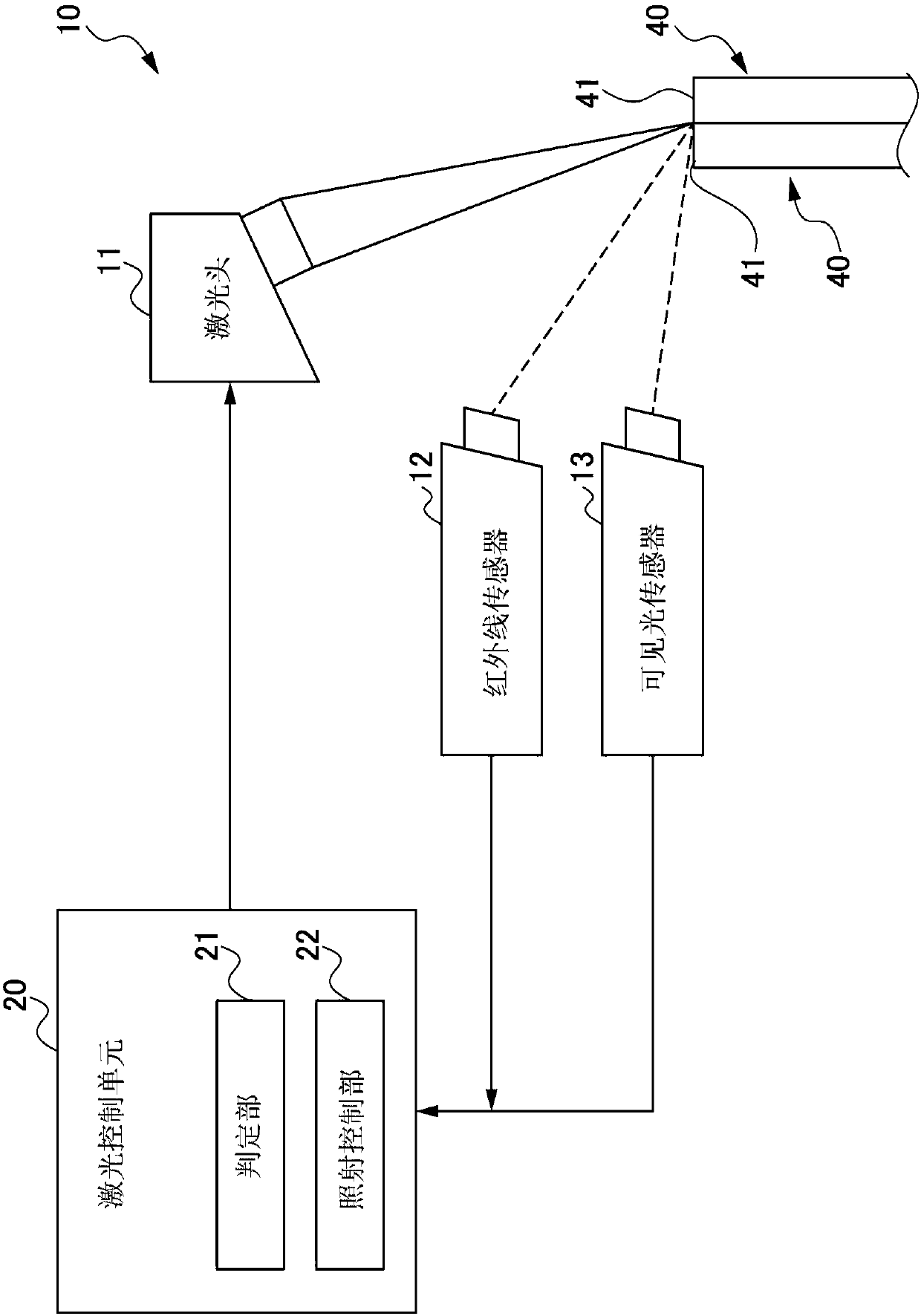

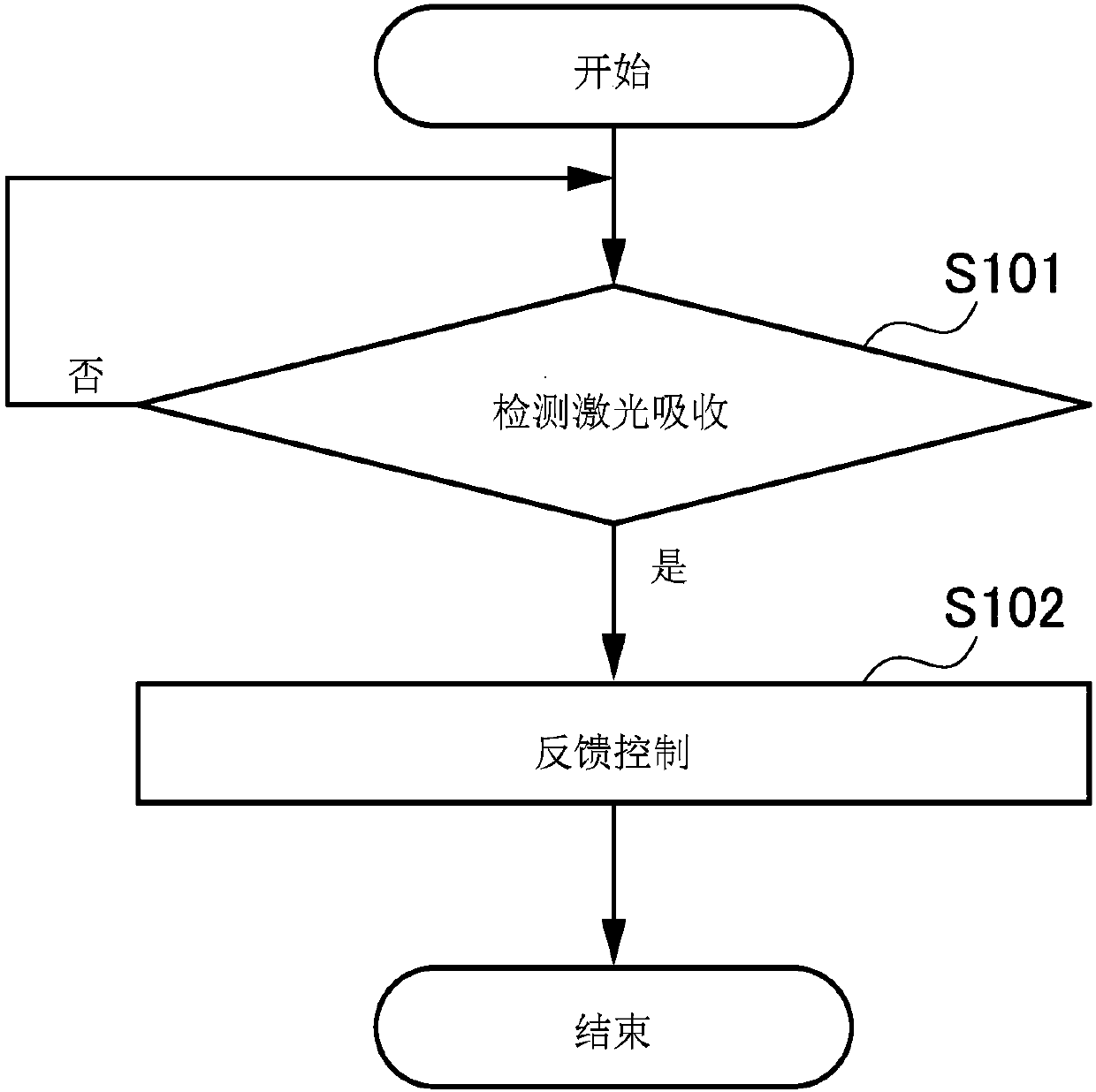

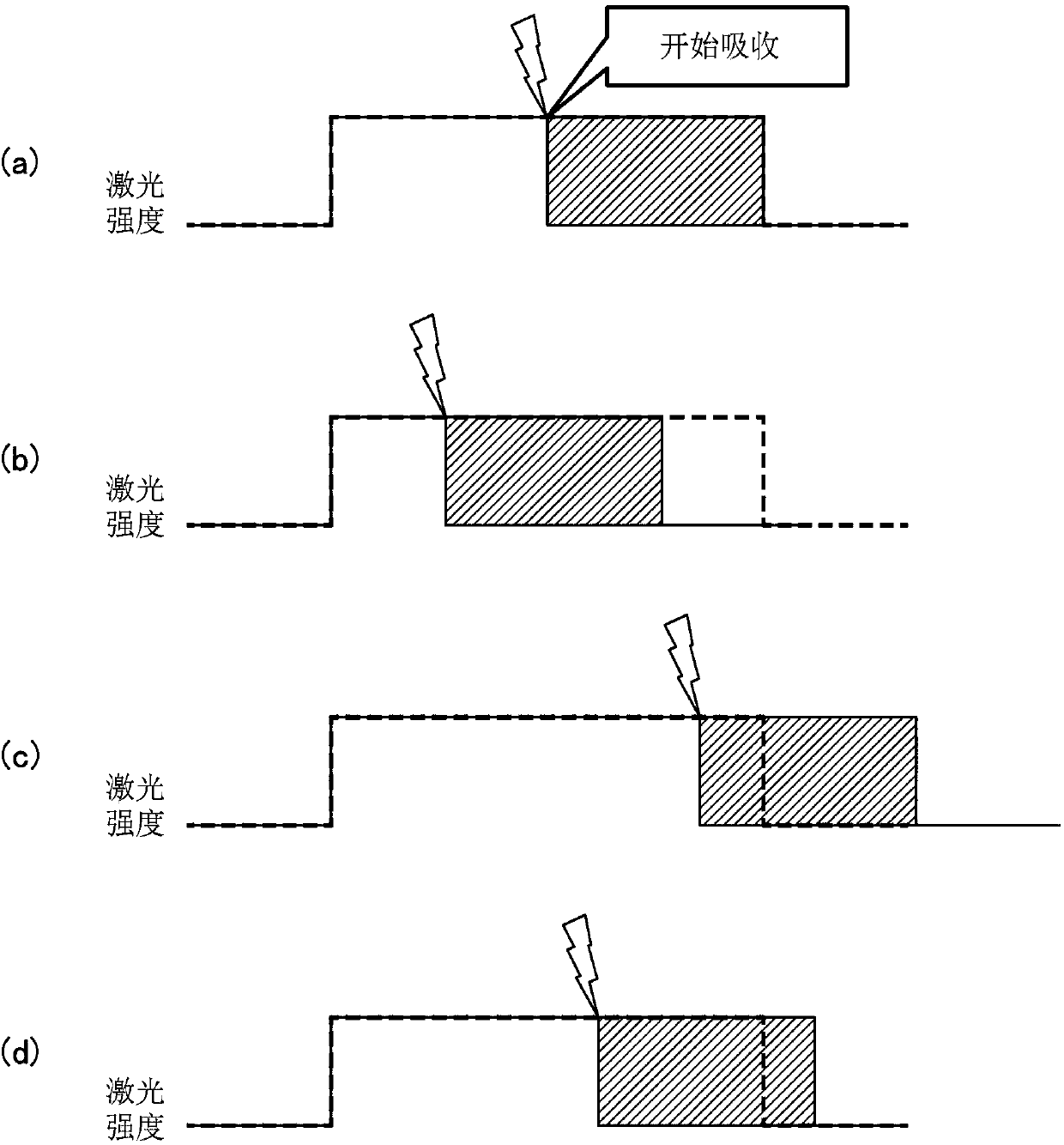

[0038] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings. figure 1 It is a figure which shows typically the cell structure of the laser welding apparatus 1 which concerns on one Embodiment of this invention. The laser welding apparatus 1 of the present embodiment performs a laser welding method of joining at least two electrical conductors 40 by laser welding.

[0039] like figure 1 As shown, the laser welding apparatus 10 includes: a laser head 11 that irradiates a laser light (laser light) to an electrical conductor 40; an infrared sensor (photodetection unit) 12 that detects infrared light; a visible light sensor (photodetection unit) 13 that detects visible light; and The laser control unit 20 performs various controls of the laser welding apparatus 10 .

[0040] The laser head 11 is a laser irradiation unit that irradiates an infrared laser beam to a workpiece to be welded. The laser beam output from a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com