High-intensity magnetic separation method of minerals

A strong magnetic separation and mineral technology, applied in chemical instruments and methods, magnetic separation, high-gradient magnetic separation, etc., can solve problems such as unsatisfactory unloading effect, failure to produce, and affect the separation effect, so as to eliminate strong magnetic operations The effect of increasing the grade and yield, increasing the output of concentrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further illustrated below in conjunction with specific embodiments, and it should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

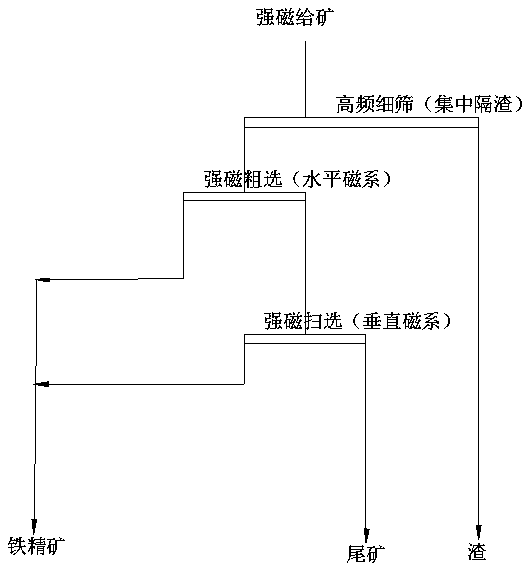

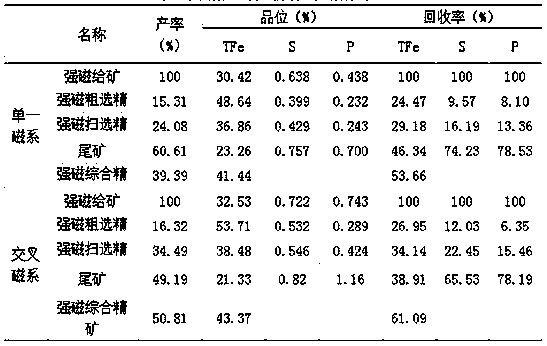

[0019] A method for strong magnetic separation of minerals, the method is as follows: in the process of strong magnetic separation, strong magnetic rough separation and sweeping adopt horizontal magnetic system and vertical magnetic system respectively to form cross magnetic field separation.

[0020] In the strong magnetic separation method of minerals, the magnetic field strength of the horizontal magnetic system is 0.8-1.0T, the diameter of the dielectric rod is 3mm, and the dielectric rods are arranged in parallel.

[0021] In the strong magnetic separation method of minerals, the magnetic field strength of the vertical magnetic system is 1.0-1.2T, the diameter of the dielectric rods is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com