Method for constructing deformation resistance models of material

A technology of deformation resistance and material deformation, applied in the field of material thermal processing, it can solve the problems of deviation of calculation results, not considering the stage of material structure change, etc., and achieve the effect of accurate rolling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The construction process of the deformation resistance model applied to low-carbon micro-alloyed steel, the specific methods and steps are as follows:

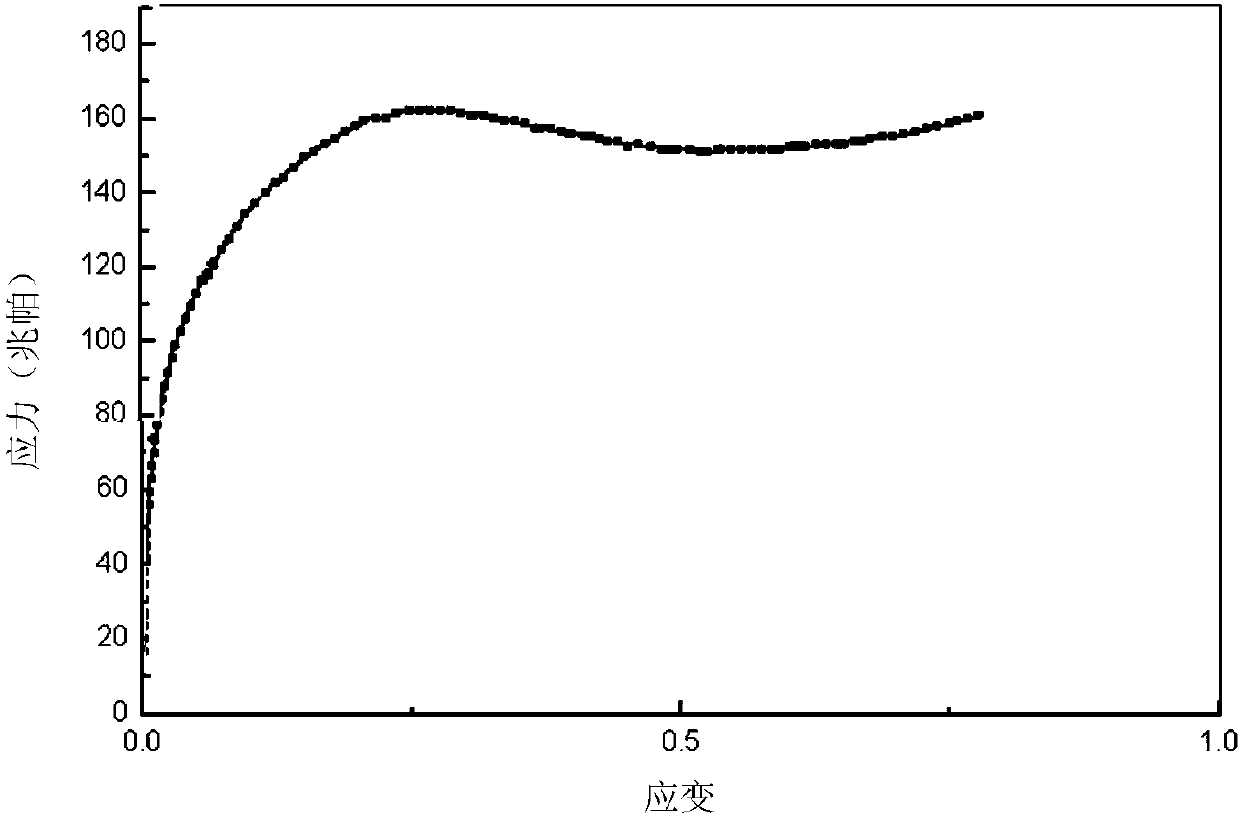

[0048] 1. A Q345 steel was subjected to a single-pass compression test using a thermal simulation testing machine, with a deformation temperature of 900-1050°C and a strain rate of 0.1-10s -1 , to obtain the stress-strain curve under the condition of given deformation temperature and deformation rate.

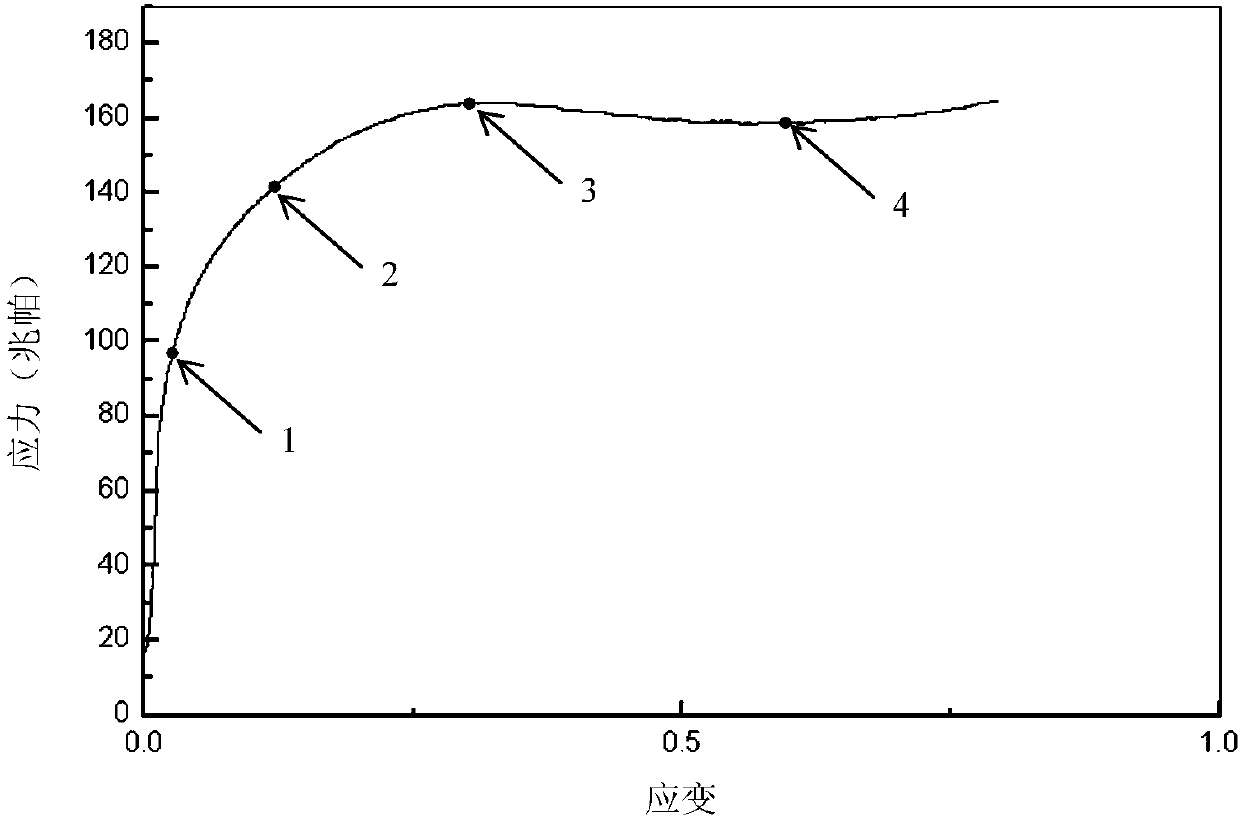

[0049] 2. Analyze the stress-strain curve to obtain critical stress, critical strain, peak stress, peak strain, steady-state stress and steady-state strain parameters. The results of single-pass compression experiments are shown in Table 1.

[0050] Table 1 Single-pass compression test results of Q345 steel

[0051]

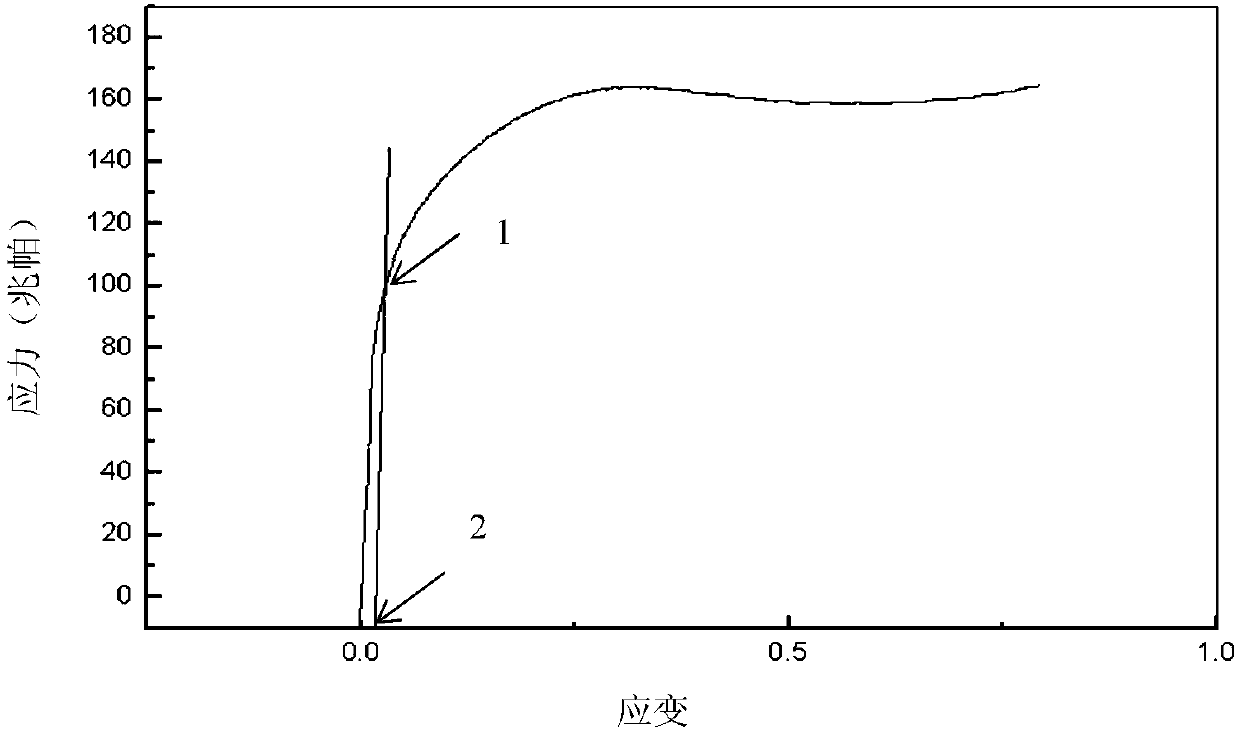

[0052] 3. In figure 1 In the stress-strain curve determination diagram, draw a straight line parallel to the initial segment of the stress-strain curve from the point where the strain is 0.002. This line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com