A high-speed response photoelectric test device

A photoelectric test, high-speed technology, applied in the direction of using optical devices to transmit sensing components, etc., can solve the problems of damage to surrounding equipment, lack of explosion-proof, low consistency, etc., to achieve long effective distance, high integration, small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

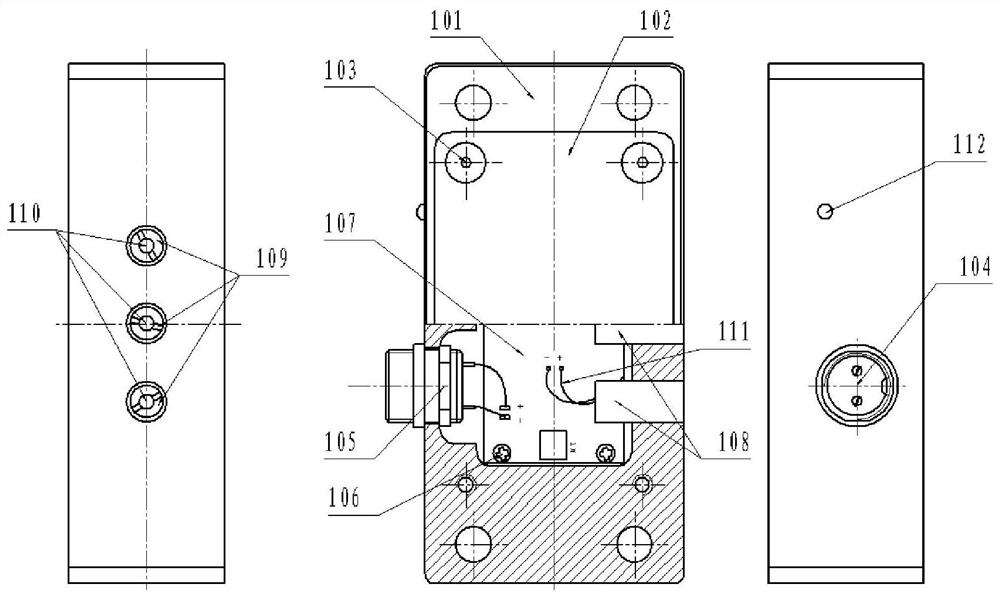

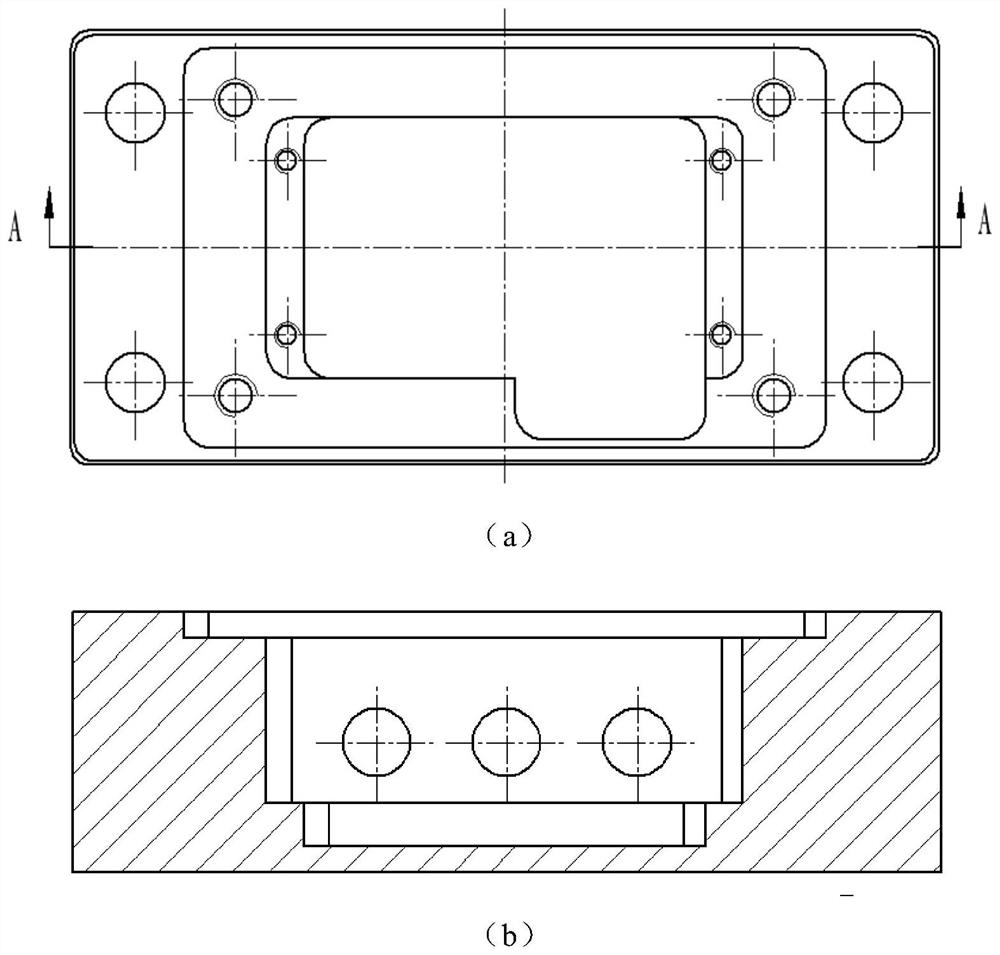

[0037] The present invention will be further described below with reference to the accompanying drawings.

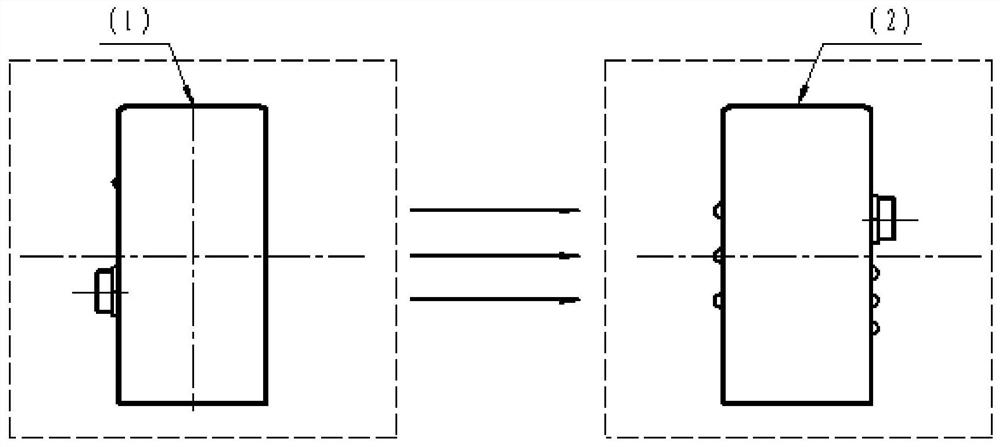

[0038] like figure 1 As shown, the high-speed response photoelectric test device includes a transmitter 1 and a receiver 2. When the transmitter 1 is powered on, the first emission state indicator 112 is on. When the first infrared emission tube 110 is aligned with the optical axis of the second receiving diode 209, the 2. The receiving status indicator light 210 is on, and when a flying object such as an explosive bolt head cuts off the optical axis, a level signal will be generated in turn. Therefore, the achievable functions of the present invention include:

[0039] First, the time detection function of the aerospace pyrotechnic separation devices such as explosive bolts from power-on to ignition is realized. Before detection, adjust the distance between the explosion bolt head and the first optical axis (bolt head acceleration section). When the explosion bolt is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com