Method for removing safrole from borneol oil

A technology for borneol oil and safrole, which is applied in the field of natural product separation, can solve problems such as time-consuming processing procedures, cumbersome processes, etc., and achieves the effects of strong operability, pure aroma, and increased content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Take 140mL HP21 resin, soak in ethanol, and elute with 95% ethanol until the effluent has no peculiar smell. Then take 2 times column volume of 80% ethanol to replace the solvent in the filler for washing. 10g borneol was adsorbed on the column, the ethanol flow rate was 1 times the column volume per hour, and the sample effluent was collected. After loading the sample, add 80% 1 column volume and 95% 1 column volume ethanol for elution, the flow rate is 2 column volumes per hour, combine the elution effluent and loading effluent, concentrate to remove ethanol, and obtain Brain essential oil.

[0040] Column cleaning: Add 2 times column volume of 95% ethanol at a flow rate of 2 times column volume per hour to clean the adsorbed safrole and impurities. After the elution is completed, prepare for the next column separation.

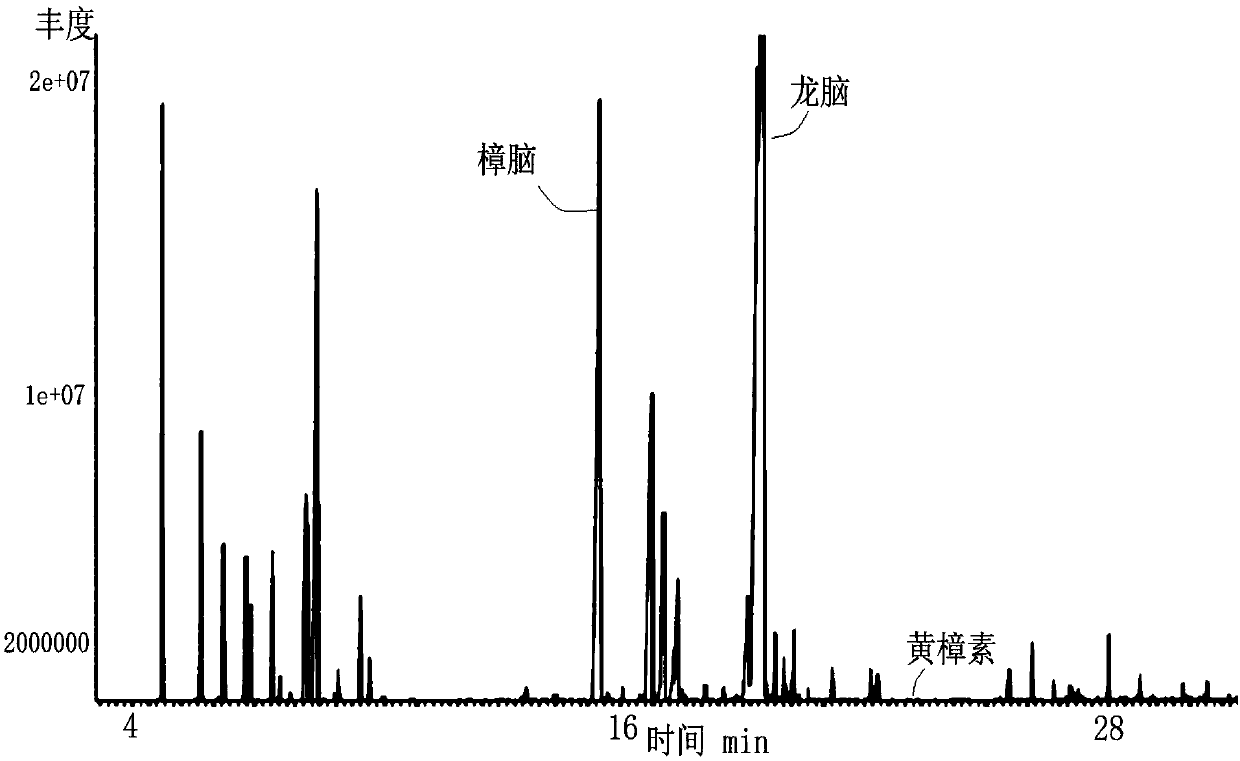

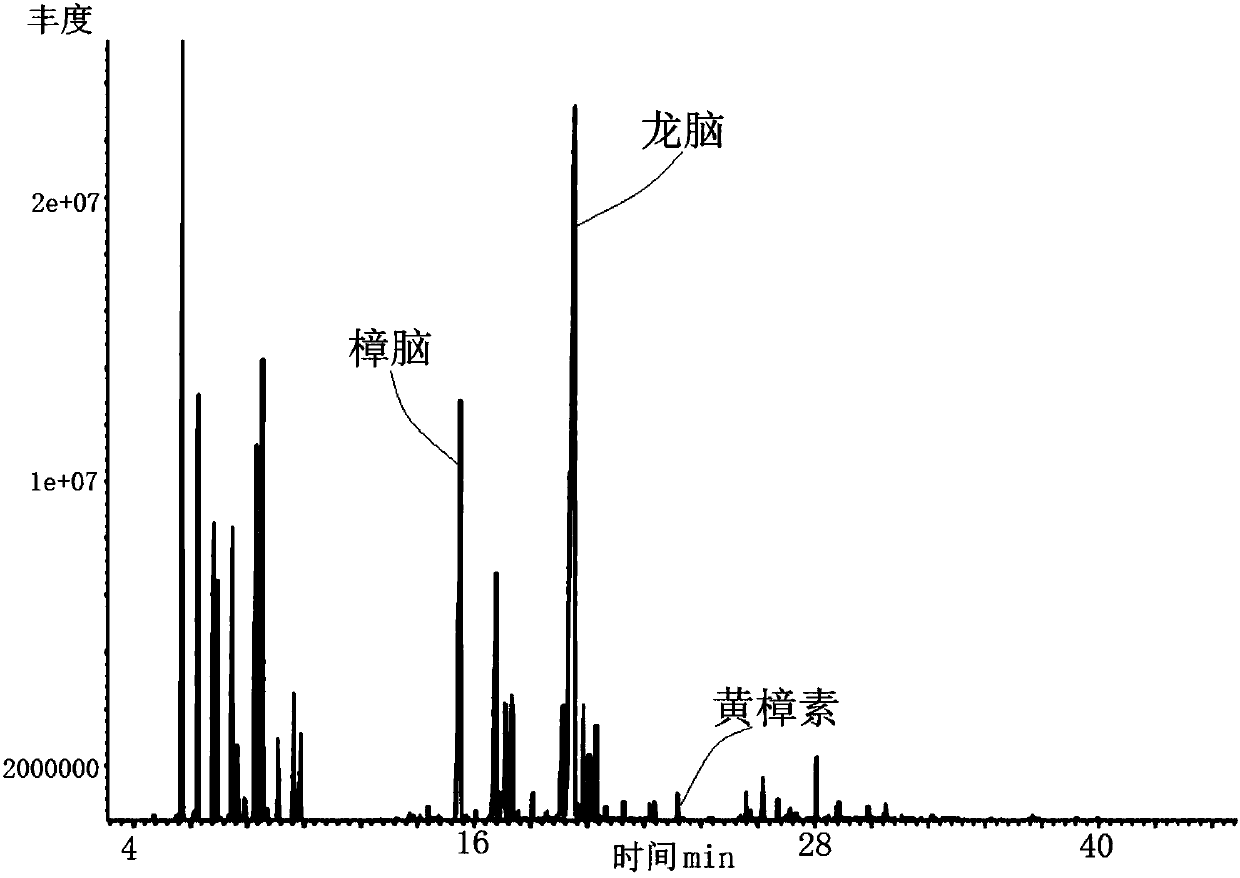

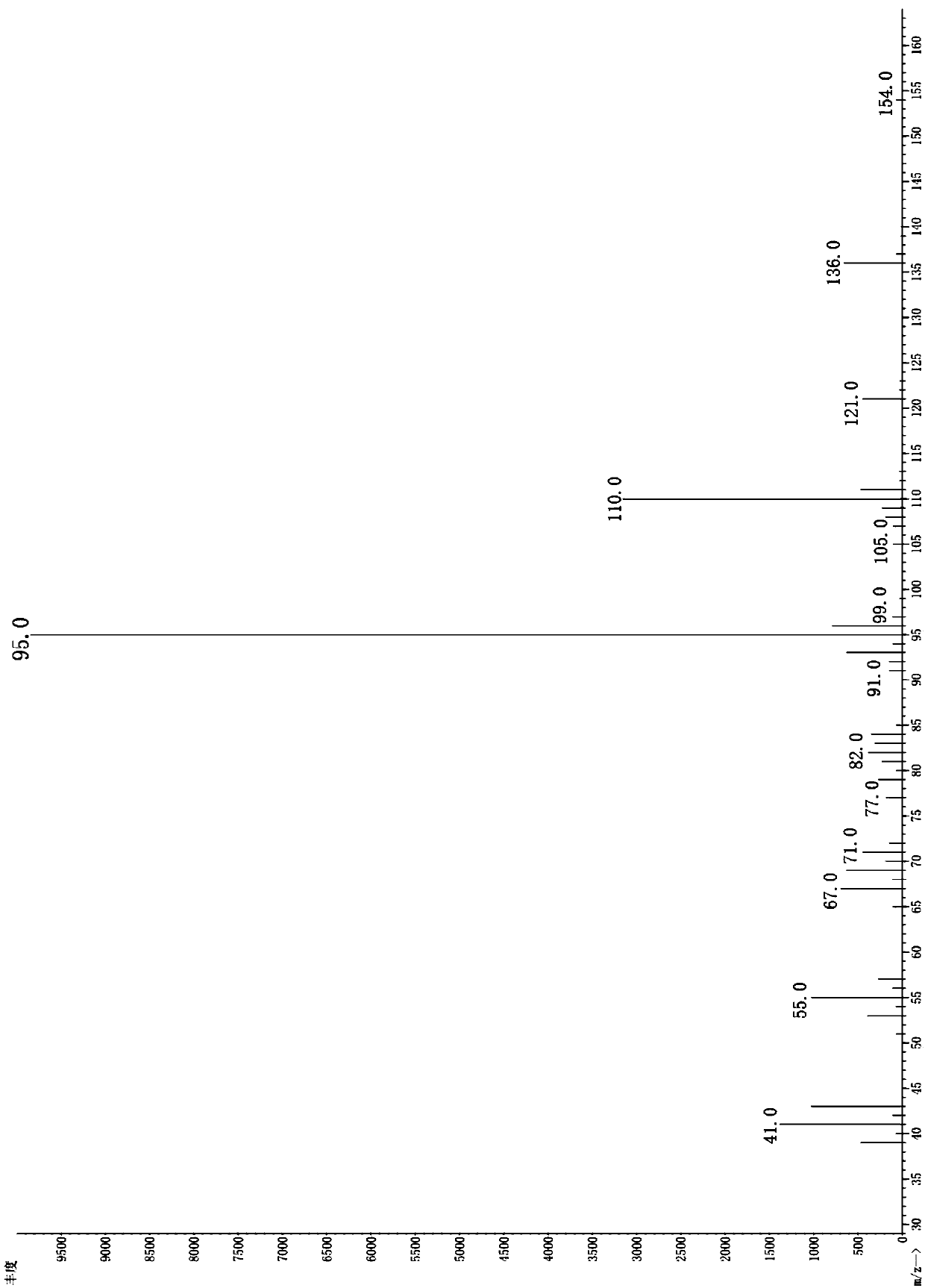

[0041] The borneol essential oil obtained in the above example 1 and the untreated borneol oil were subjected to GC-MS component detection, where...

Embodiment 2

[0045] Take 140mL HP20 resin, soak in ethanol, and elute with 95% ethanol until the effluent has no peculiar smell. Then take 50% ethanol of 3 times of the column volume, replace the solvent in the filler, and wash. 30g borneol was adsorbed on the column, the ethanol flow rate was 1.5 times the column volume per hour, and the sample effluent was collected. After loading the sample, add 50% 1 column volume methanol, 1.5 column volume 85% methanol for gradient elution, the flow rate is 1 column volume per hour, combine the elution effluent and loading effluent, concentrate to remove the solvent, Get borneol essential oil.

[0046] Column cleaning: Add 2 times column volume of 95% ethanol at a flow rate of 2 times column volume per hour to clean the adsorbed safrole and impurities. After the elution is completed, prepare for the next column separation.

Embodiment 3

[0048] Take 140mL Amberlite XAD-4 resin, soak in ethanol, and elute with 95% ethanol until the effluent has no peculiar smell. Then take 2.5 times of column volume of 70% ethanol to replace the solvent in the filler for washing. 20g borneol was adsorbed on the column, the ethanol flow rate was 2 times the column volume per hour, and the sample effluent was collected. After loading the sample, add 80% 2-times column volume propanol for elution, the flow rate is 1.5 times the column volume per hour, combine the elution effluent and loading effluent, concentrate to remove the solvent, and obtain borneol essential oil.

[0049] Column cleaning: add 3 times column volume of 95% ethanol at a flow rate of 2 times column volume per hour to clean the adsorbed safrole and impurities. After the elution is complete, prepare for the next column separation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com