Three-row weighing and filling machine

A filling machine and weighing technology, applied in the directions of packaging, transportation and packaging, and the type of packaged items, can solve the problems of restricting the filling efficiency of multi-container filling machines, long time for changing containers, and limited number of tube heads. , to achieve the effect of improving filling efficiency, facilitating pushing barrels and filling materials, and reducing replacement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

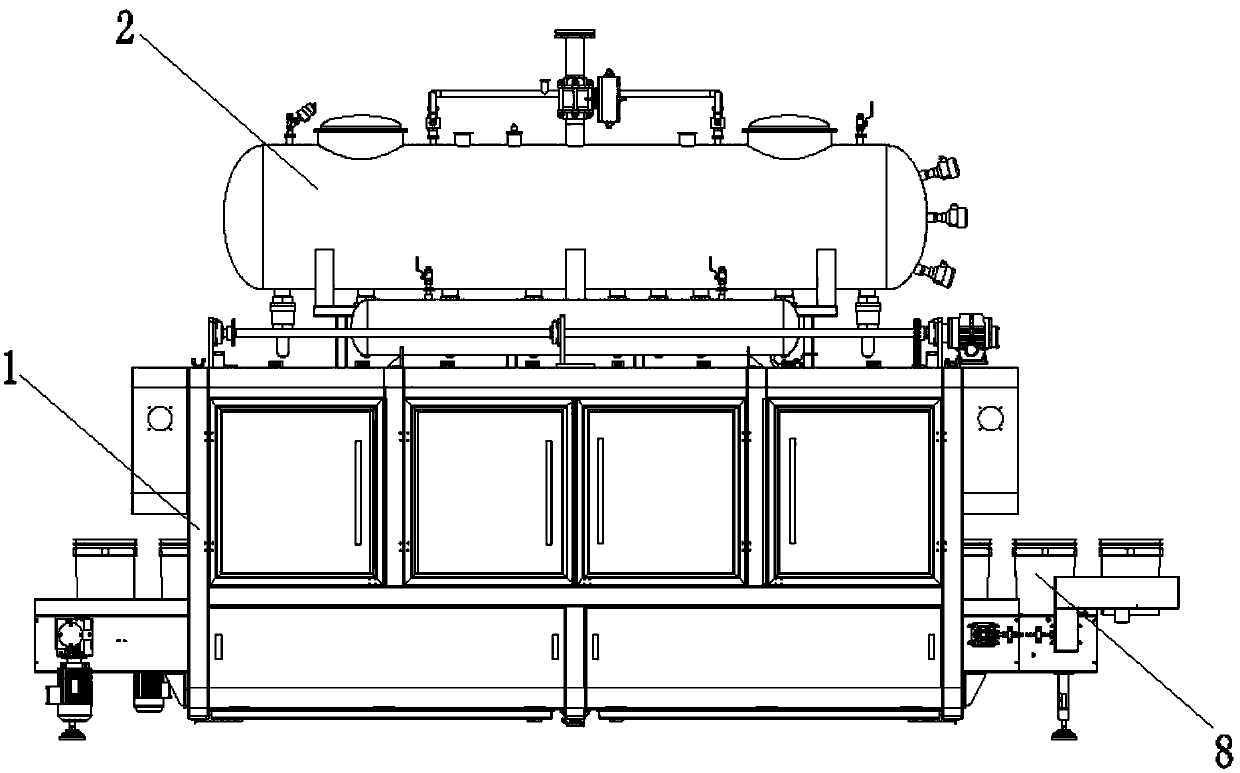

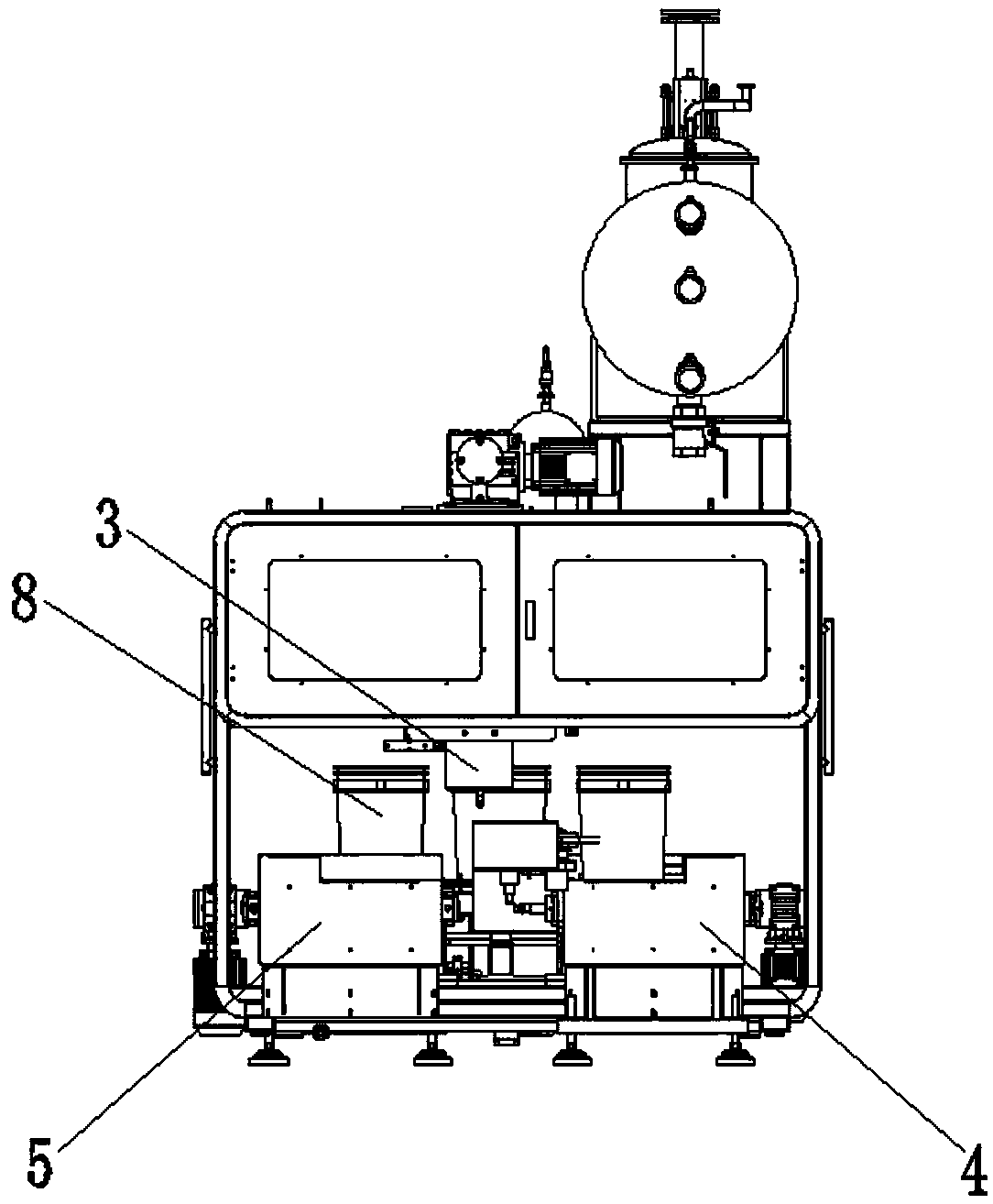

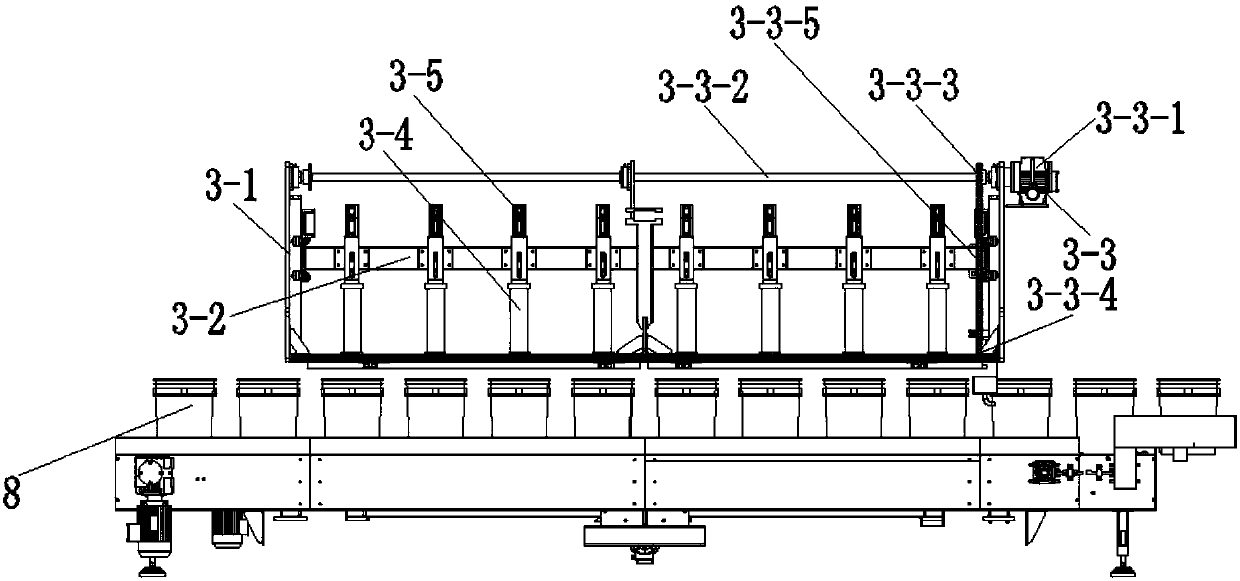

[0043] See Figure 1 to Figure 11 , The three-row weighing filling machine of this embodiment includes a cabinet 1, a material tank 2, a filling mechanism 3, a container feeding mechanism 4, a container sending mechanism 5, a weighing filling platform 6 and a container pushing mechanism 7.

[0044] The material tank 2 is fixed on the top of the cabinet 1 . The filling mechanism 3 is arranged in the cabinet 1 and communicated with the material tank 2 . The container feeding mechanism 4 passes through from one side of the cabinet 1 , and the container sending mechanism 5 passes through from the other side of the cabinet 1 . The weighing filling platform 6 is arranged in the cabinet 1, and is located between the container feeding mechanism 4 and the container sending mechanism 5, and is also located directly below the filling mechanism 3. The container pushing mechanism 7 is arranged in the cabinet 1, and the container pushing mechanism 7 pushes the container 8 to move between ...

Embodiment 2

[0054] This embodiment is basically the same as Embodiment 1, except that the container 8 is a bottle-shaped container. The container pushing mechanism 7 is arranged above the container feeding mechanism 4 . The container pushing mechanism 7 comprises a bottle push support, a bottle push cylinder and a bottle push cross bar. The cylinder body of the bottle pushing cylinder is arranged on the bottle pushing support. Push bottle cylinder. The bottle pushing cylinder drives the bottle pushing cross bar to move between the top of the container feeding mechanism 4 and the top of the weighing filling platform 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com