Polishing device of motor shaft

A technology of polishing device and motor shaft, applied in the direction of grinding drive device, surface-polished machine tool, grinding machine parts, etc. Improve polishing efficiency and polishing quality, save labor, and avoid polishing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

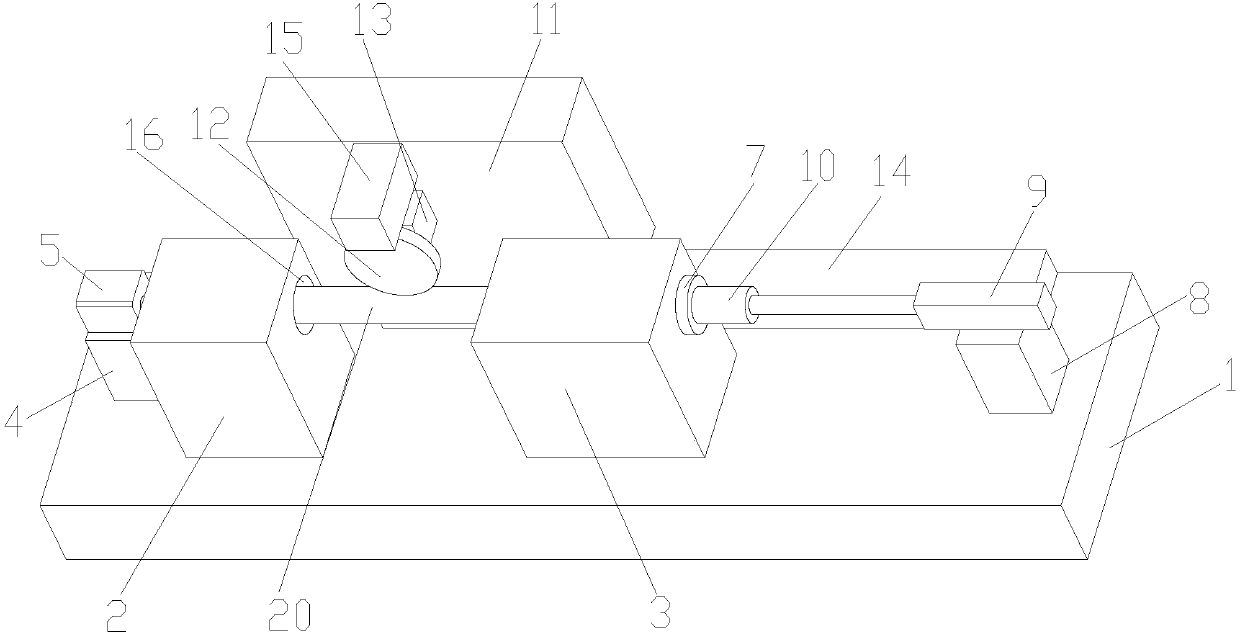

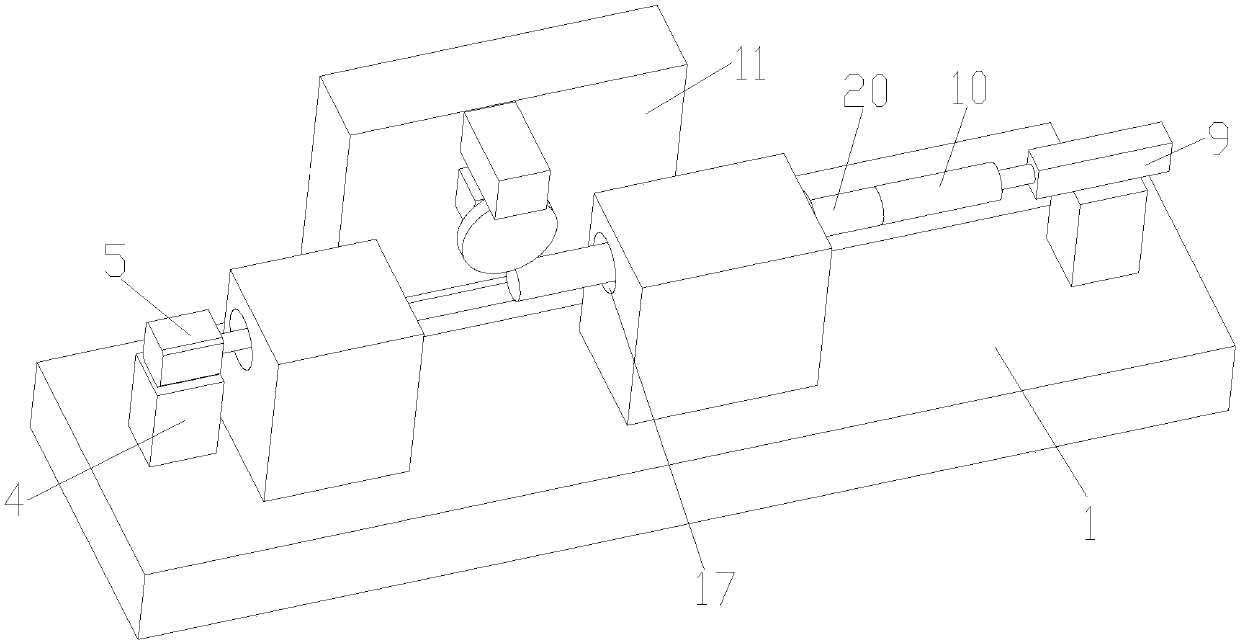

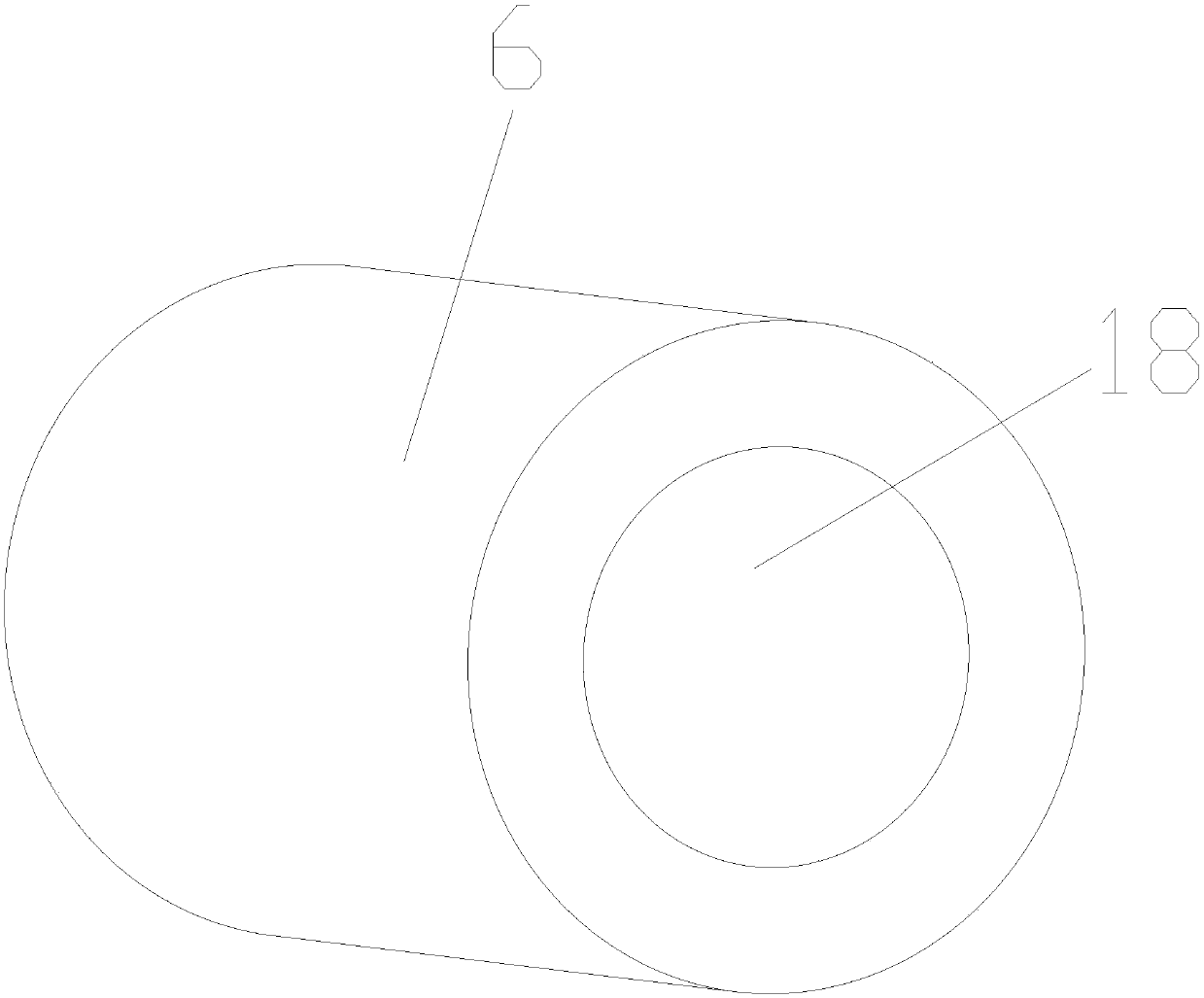

[0017] as attached Figure 1-3 The shown polishing device of a motor shaft according to the present invention includes a base 1, a left positioning block 2, a right positioning block 3, a motor seat 4, a motor 5, a left cylindrical block 6, a fixing cylinder 7, and a cylinder seat 8 , Telescopic cylinder 9, electromagnet block 10, substrate 11 and polishing assembly; The base 1 is provided with a left positioning block 2 and a right positioning block 3; Positioning hole 16 and right positioning hole 17, and above-mentioned two positioning holes are located on the same axis line; One side of described left positioning block 2 is provided with the motor 5 that is positioned on motor seat 4; One side of the rotating shaft of described motor 5 A left cylindrical block 6 positioned in the left positioning hole 16 is provided, and a housin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com