Flyknit and cording embroidery connecting structure and upper

A connection structure and rope embroidery technology, applied in the direction of shoe uppers, footwear, boot legs, etc., can solve the problems of extremely uncomfortable wearing, inability to planar transition connection, and unevenness of joints, and achieve novel structure and free style design High degree, highlight the effect of individuality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

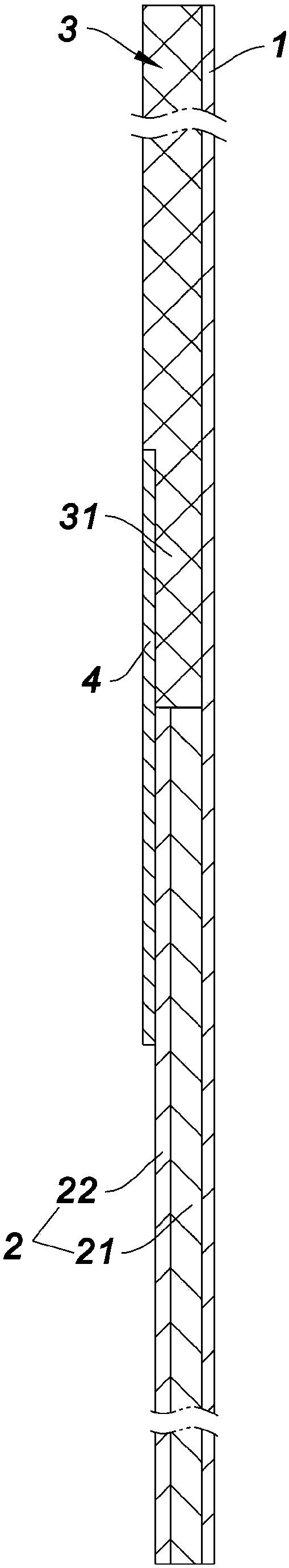

[0028] Such as figure 1 As shown, a connection structure between flying weaving and rope embroidery described in this embodiment includes a mesh layer 1, a rope embroidery layer 2, a flying weaving layer 3 and a rope embroidery layer 4; the rope embroidery layer 2 is embroidered on On the mesh layer 1, the cord embroidery layer 2 includes a basic cord embroidery layer 21 and a pattern cord embroidery layer 22; the basic cord embroidery layer 21 is between the mesh cloth layer 1 and the pattern cord embroidery layer 22; The woven fabric layer 3 is formed with a thinner region 31, and an edge of the thinner region 31 is abutted with an edge of the cord embroidery layer 2; Connect together to fix the flying weaving layer 3 so as to facilitate the rope embroidery of the rope embroidery layer 4 in the later stage, and the stitching position is in the thinner region 31 of the flying weaving layer 3, so that the rope embroidery adding layer 4 is completed Finally, the stitching trac...

Embodiment 2

[0030] Such as Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 As shown, a shoe upper described in this embodiment includes a mesh cloth layer 1, a cord embroidery layer 2, a flying weaving layer 3 and a cord embroidery layer 4; the cord embroidery layer 2 is embroidered on the mesh cloth layer 1; The flying woven layer 3 is formed with a thinner region 31, and an edge of the thinner region 31 is abutted with an edge of the cord embroidery layer 2; the flying woven layer 3 and the mesh layer 1 pass through In order to fix the flying weaving layer 3 so as to facilitate the rope embroidery of the rope embroidery adding layer 4 in the later stage, the stitching position is in the thinner region 31 of the flying weaving layer 3, so that the rope embroidery After the addition layer 4 is completed, the stitching traces can be covered without affecting the appearance of the product. Through such a design, the top surface of the cord embroidery layer 2 and the top surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com