Plant nutrition bowl used for saline-alkali soil and based on coal-fired flue gas desulfurization gypsum

A technology for desulfurizing gypsum and coal-fired flue gas, applied in the field of plant nutrition bowls, can solve problems such as greening problems in saline-alkali land, and achieve the effect of facilitating environmental greening and park green space construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

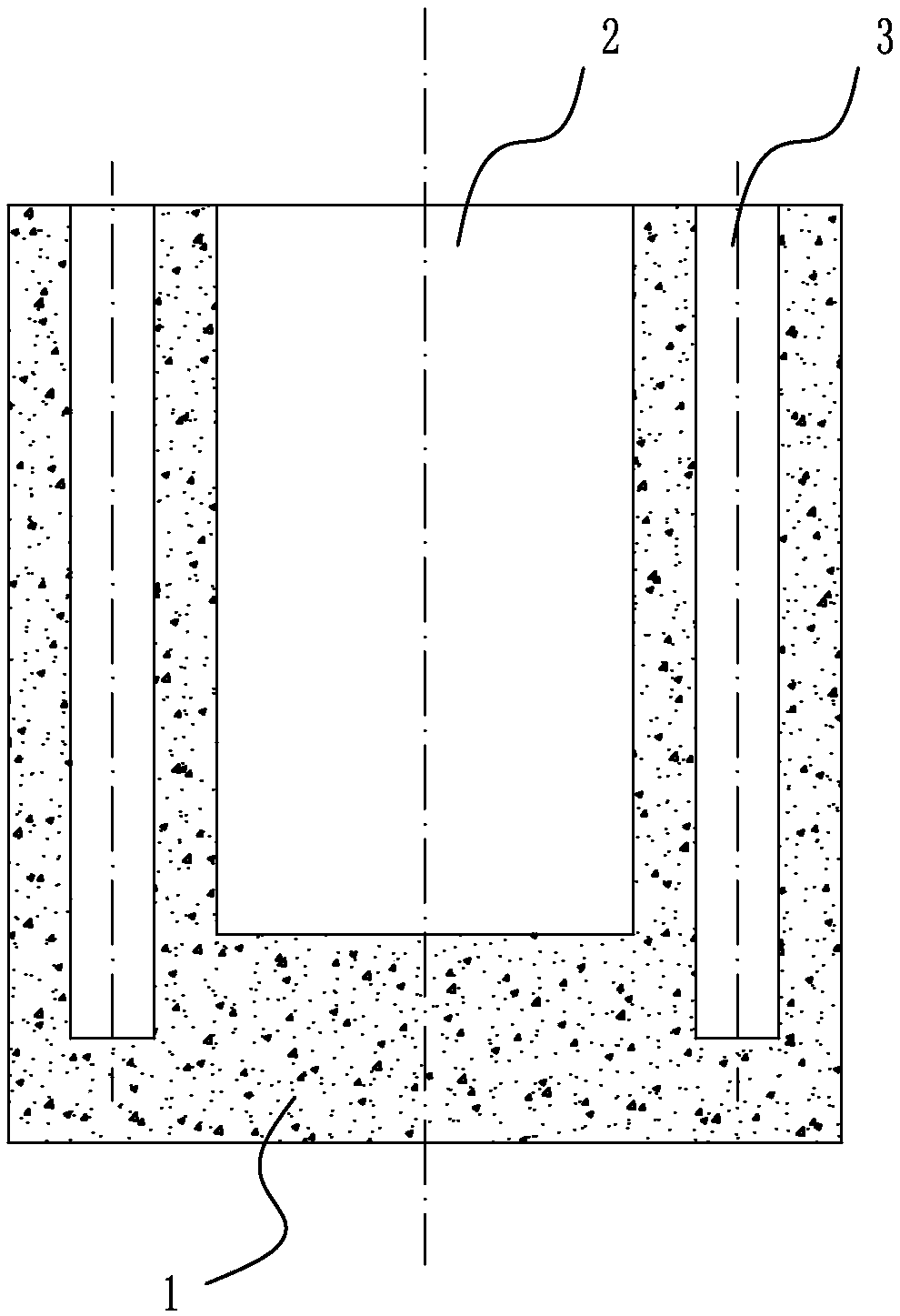

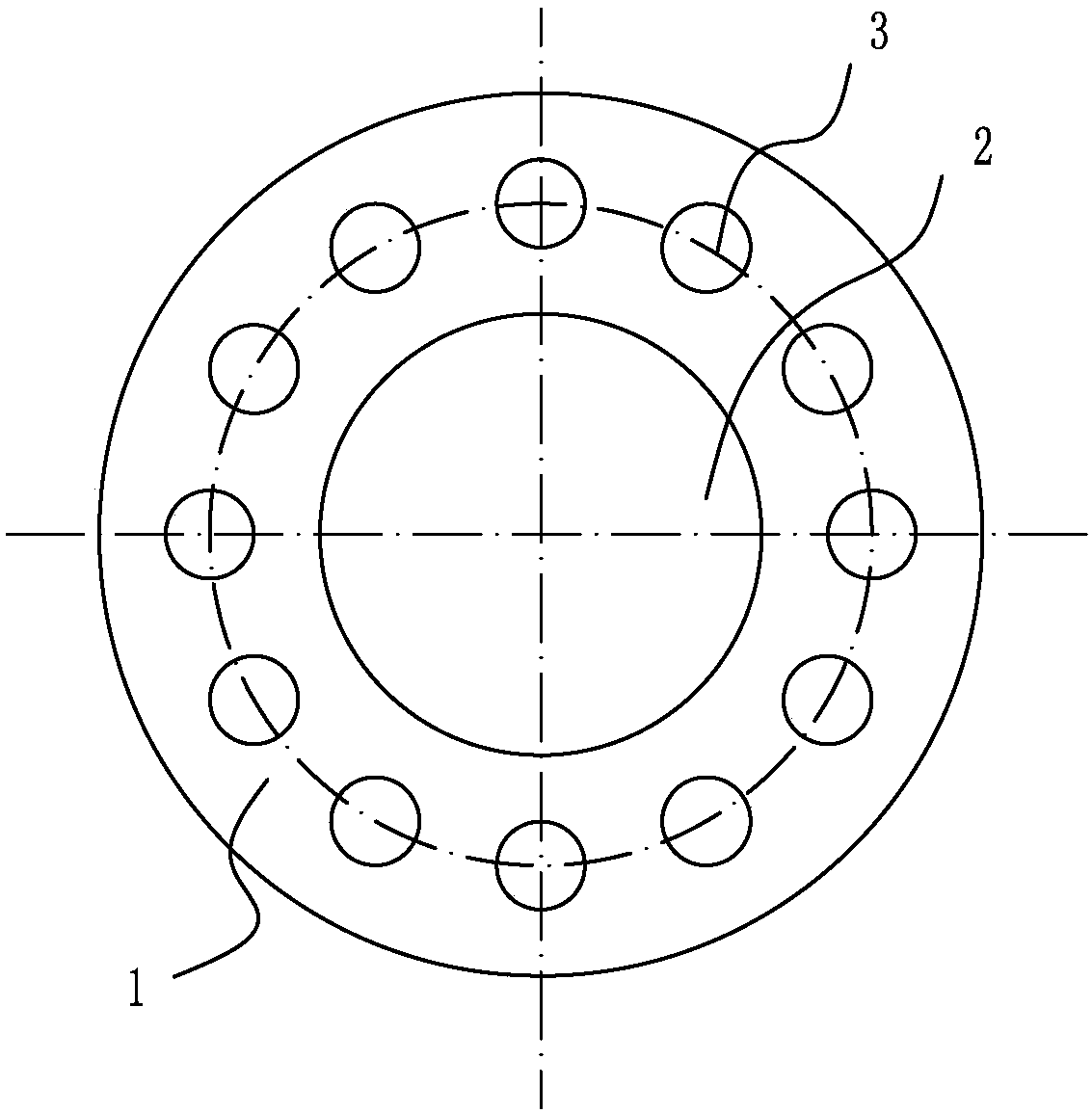

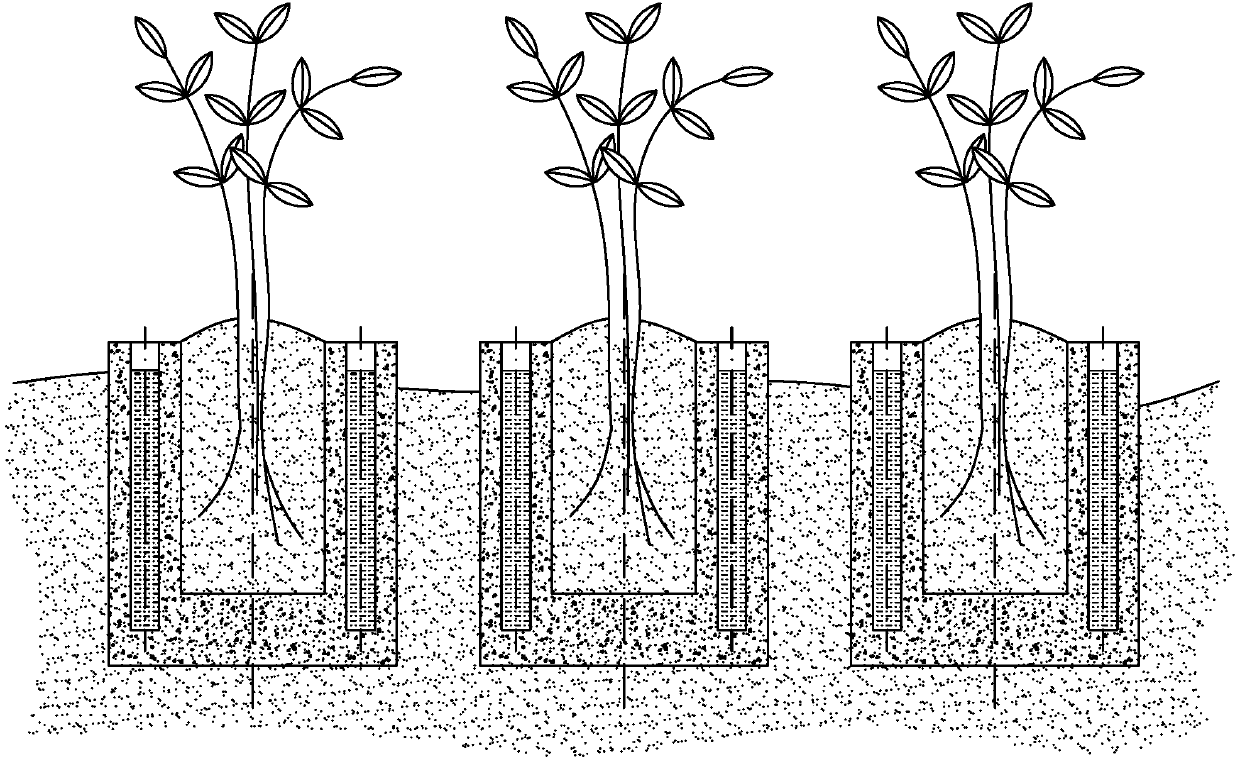

[0021] Embodiment 1: A plant nutrition pot for saline-alkali land based on coal-fired flue gas desulfurization gypsum, including a pot body 1, a planting hole 2 opening upwards is provided in the center of the pot body 1, and the periphery of the pot body 1 surrounds the planting The hole 2 is arranged with a water storage hole 3 opening upward, and the material of the pot body 1 includes coal-fired flue gas desulfurization gypsum.

[0022] In this embodiment, the pot body 1 includes the following components in parts by weight: 40 parts of coal-fired flue gas desulfurization gypsum; 20 parts of plant straw powder; and 20 parts of ordinary raw soil. The length of the plant straw powder is not more than 2mm.

[0023] The manufacturing method of the present embodiment comprises the following steps:

[0024] (1) Raw material preparation: crush the plant stalks and take ordinary raw soil for later use;

[0025] (2) Mixing of raw materials: put coal-fired flue gas desulfurization ...

Embodiment 2

[0028] Embodiment 2: A plant nutrition pot for saline-alkali land based on coal-fired flue gas desulfurization gypsum, including a pot body 1, the center of the pot body 1 is provided with an upwardly opening planting hole 2, and the periphery of the pot body 1 surrounds the planting The hole 2 is arranged with a water storage hole 3 opening upward, and the material of the pot body 1 includes coal-fired flue gas desulfurization gypsum.

[0029] In this embodiment, the pot body 1 includes the following components in parts by weight: 60 parts of coal-fired flue gas desulfurization gypsum; 15 parts of plant straw powder; and 15 parts of ordinary raw soil. The length of the plant straw powder is not more than 2mm.

[0030] The manufacturing method of the present embodiment comprises the following steps:

[0031] (1) Raw material preparation: crush the plant stalks and take ordinary raw soil for later use;

[0032] (2) Mixing of raw materials: put coal-fired flue gas desulfurizat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com