Chickpea active peptide, combination and preparation method

A technology of chickpea and active peptides, which is applied in the field of preparation of chickpea active peptides, can solve the problems of unsuitable industrialization conditions, unfavorable nutritional components, and darkening of product color, and achieve the effect of improving health care functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

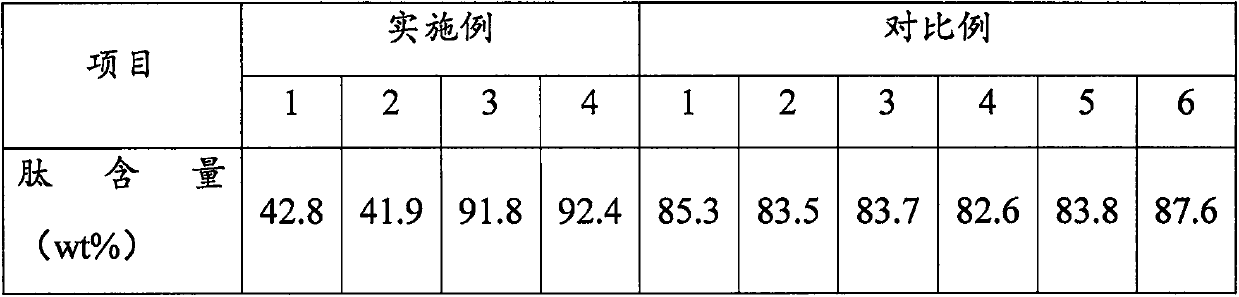

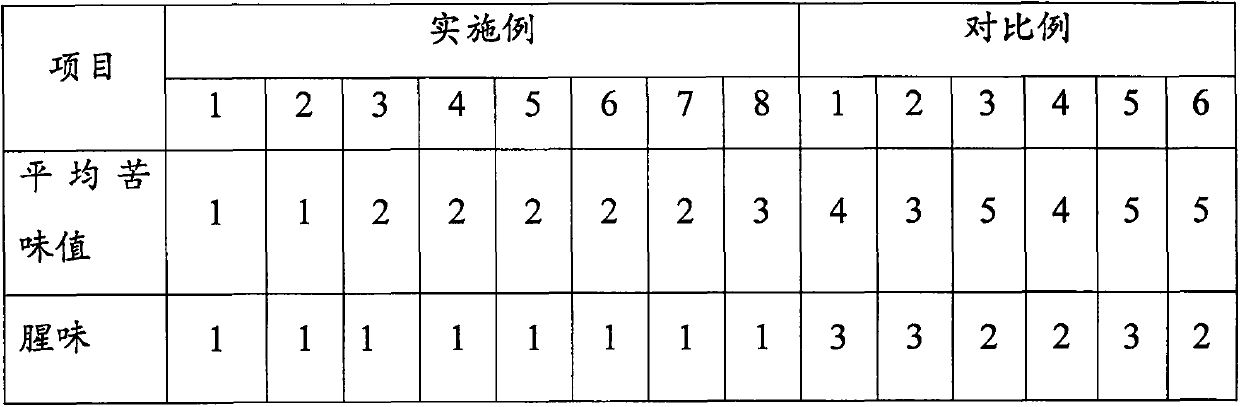

Examples

preparation example Construction

[0039]

[0040] The preparation method of chickpea active peptide of the present invention comprises the following steps:

[0041] A. Add chickpea flour to water, adjust the pH to 8-9, soak for 22-26 hours, separate the solid and liquid, and take the supernatant;

[0042] B. Adjust the pH of the supernatant to 4-6 for precipitation, separate the solid from the liquid, and take the solid part;

[0043] C. Add water to the solid part, heat at 80-100°C for 20-40 minutes, and then homogenize to obtain a suspension;

[0044] D. Adjust the pH of the suspension to 5-9, add an enzyme preparation for enzymolysis; the enzyme preparation is composed of flavor protease, bromelain and pepsin, and the weight of the flavor protease, bromelain and pepsin The ratio is 2-3:1-2:1-2; the enzymolysis temperature is 40-65°C, and the enzymolysis time is 1.5-7 hours to obtain the enzymolysis solution;

[0045] E. The enzymatic hydrolyzate is deenzyme-treated, and then made into chickpea active pe...

Embodiment 1

[0078] The preparation method of the whole nutritional chickpea active peptide comprises the following steps:

[0079] A. Superfinely pulverize the dried chickpea, pass through a 400-mesh sieve to obtain chickpea powder; add the chickpea powder to water of 4 times the weight of the chickpea powder, mix, and adjust to pH with sodium hydroxide solution 8. Soak for 24 hours; mechanically stir, centrifuge, and take the supernatant;

[0080] B, the supernatant is adjusted to pH5 with acetic acid solution, precipitated protein, mechanically stirred, centrifuged, and the solid part is taken;

[0081] C. Add water to the solid part, heat at 95°C for 20min, and then homogenize to obtain a suspension;

[0082] D. Adjust the pH of the suspension to 8, add an enzyme preparation for enzymolysis to obtain an enzymolysis solution; the enzyme preparation is composed of flavor protease, bromelain and pepsin in a weight ratio of 2.5:1.5:1; the enzyme preparation The dosage is 0.5wt% of the we...

Embodiment 2

[0085] The preparation method of the whole nutritional chickpea active peptide comprises the following steps:

[0086] A. Superfinely pulverize the dried chickpeas, pass through a 400-mesh sieve to obtain chickpea powder; add the chickpea powder to 3.5 times the weight of the chickpea powder, mix, and adjust the pH to 9 with sodium hydroxide solution , soaked for 24 hours; mechanically stirred, centrifuged, and the supernatant was taken;

[0087] B. Adjust the supernatant to pH6 with acetic acid solution, precipitate protein, mechanically stir, centrifuge, and get the solid part;

[0088] C. Add water to the solid part, heat at 95°C for 20min, and then homogenize to obtain a suspension;

[0089] D. Adjust the pH of the suspension to 7.5, add an enzyme preparation for enzymolysis to obtain an enzymolysis solution; the enzyme preparation is composed of flavor protease, bromelain and pepsin in a weight ratio of 1.4: 1.6: 1.2; the enzyme preparation The dosage is 0.4wt% of the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com