A kind of treatment system and method for improving long-term adsorption performance of ammonia nitrogen adsorption material

An adsorption material and treatment system technology, which is applied in the field of treatment systems for improving the long-term adsorption performance of ammonia nitrogen adsorption materials, can solve the problems of unsatisfactory continuous use effect of ammonia nitrogen adsorption materials, and achieves reduction of operation and maintenance costs, remarkable effect, and improvement of long-term operation. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

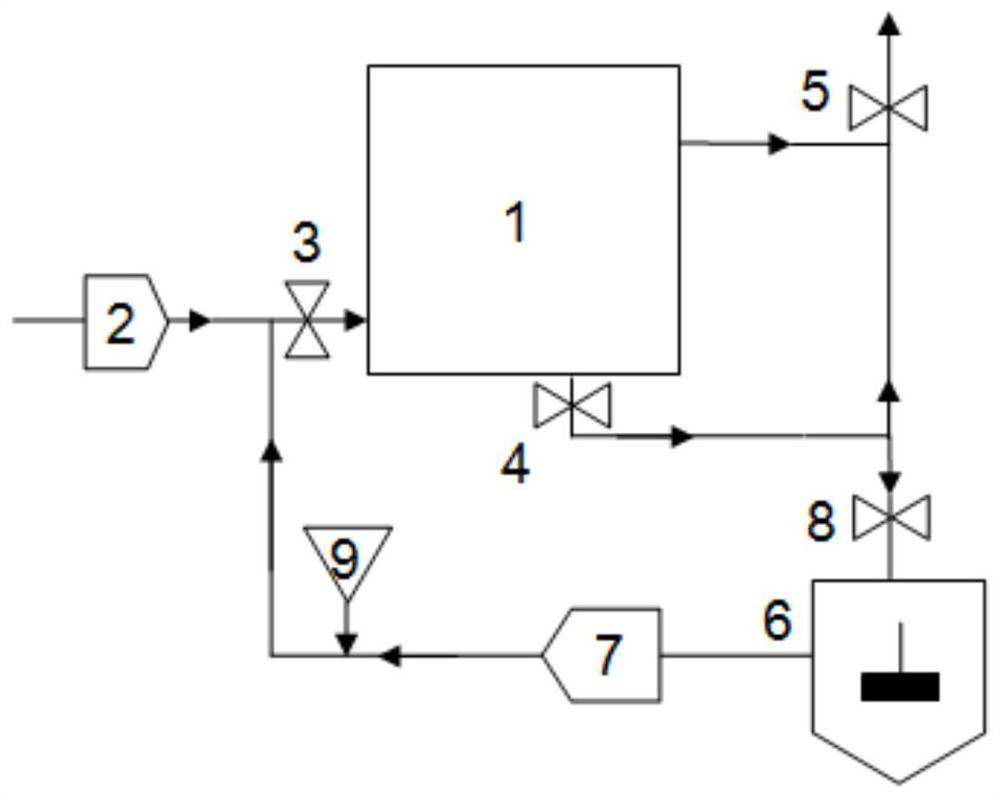

[0034] A system for the treatment of ammonia nitrogen-containing wastewater or polluted water bodies, such as figure 1As shown, it includes an ammonia nitrogen adsorption unit and a regeneration unit. The ammonia nitrogen adsorption unit includes a sequentially connected water inlet pump 2, water inlet valve 3, a filter bed 1 filled with adsorption materials, and a vent valve group. The regeneration unit includes a sequentially connected regeneration liquid storage tank. 6 and the regeneration liquid inlet pump 7, the regeneration liquid storage tank 6 is equipped with regeneration liquid, the regeneration liquid inlet pump 7 is connected to the pipeline between the water inlet pump 2 and the water inlet valve 3, and the regeneration liquid storage tank 6 is also connected to the filter bed 1 and recovered from The regenerated liquid flowing out of the filter bed 1 after regenerating and treating the adsorbent material is also provided with a regenerated liquid return valve 8 b...

Embodiment 2

[0039] This embodiment is roughly the same as Embodiment 1. In this embodiment, the adsorption material is modified zeolite, the oxidizing agent is hypochlorous acid and sodium hypochlorite, the regeneration solution is potassium chloride solution, and the concentration is 1mol / L, and the precipitating agent is sodium hydroxide. , the ratio of the oxidizing agent to the regeneration liquid is 0.1, and the volume of the regeneration liquid is 0.8 times the volume of the filter bed.

Embodiment 3

[0041] This embodiment is roughly the same as Embodiment 1. In this embodiment, the adsorption material is molecular sieve, the oxidant is calcium hypochlorite, the regeneration solution is sodium chloride, the concentration is 100mol / L, the precipitating agent is calcium hydroxide, the oxidant and regeneration The ratio of liquid to liquid is 10, and the volume of the regeneration liquid is 10.0 times the volume of the filter bed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com