Constant-volume detonation combustion test device and method with function of monitoring detonation wave fluctuation behavior

A combustion test and detonation wave technology, applied in the direction of internal combustion engine testing, etc., can solve problems such as damage, the inability to obtain piston pressure, and the inability to stably generate severe knocking, and achieve the effect of low cost and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] The present invention will be described in further detail below through specific examples, which only illustrate the present invention and do not limit the present invention in any form.

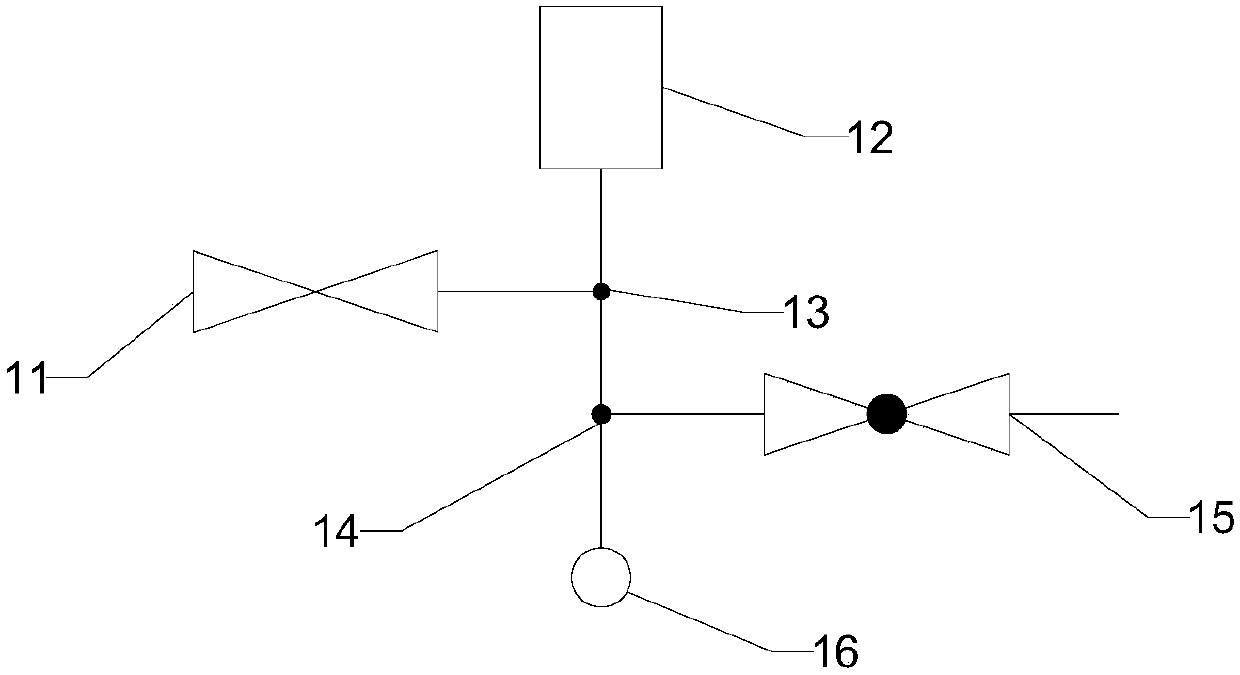

[0031] The constant-volume detonation incendiary bomb system of the present invention comprises: a constant-volume detonation incendiary bomb body, an air intake system, a high-energy ignition system and a data acquisition and analysis system. The specific components are described below:

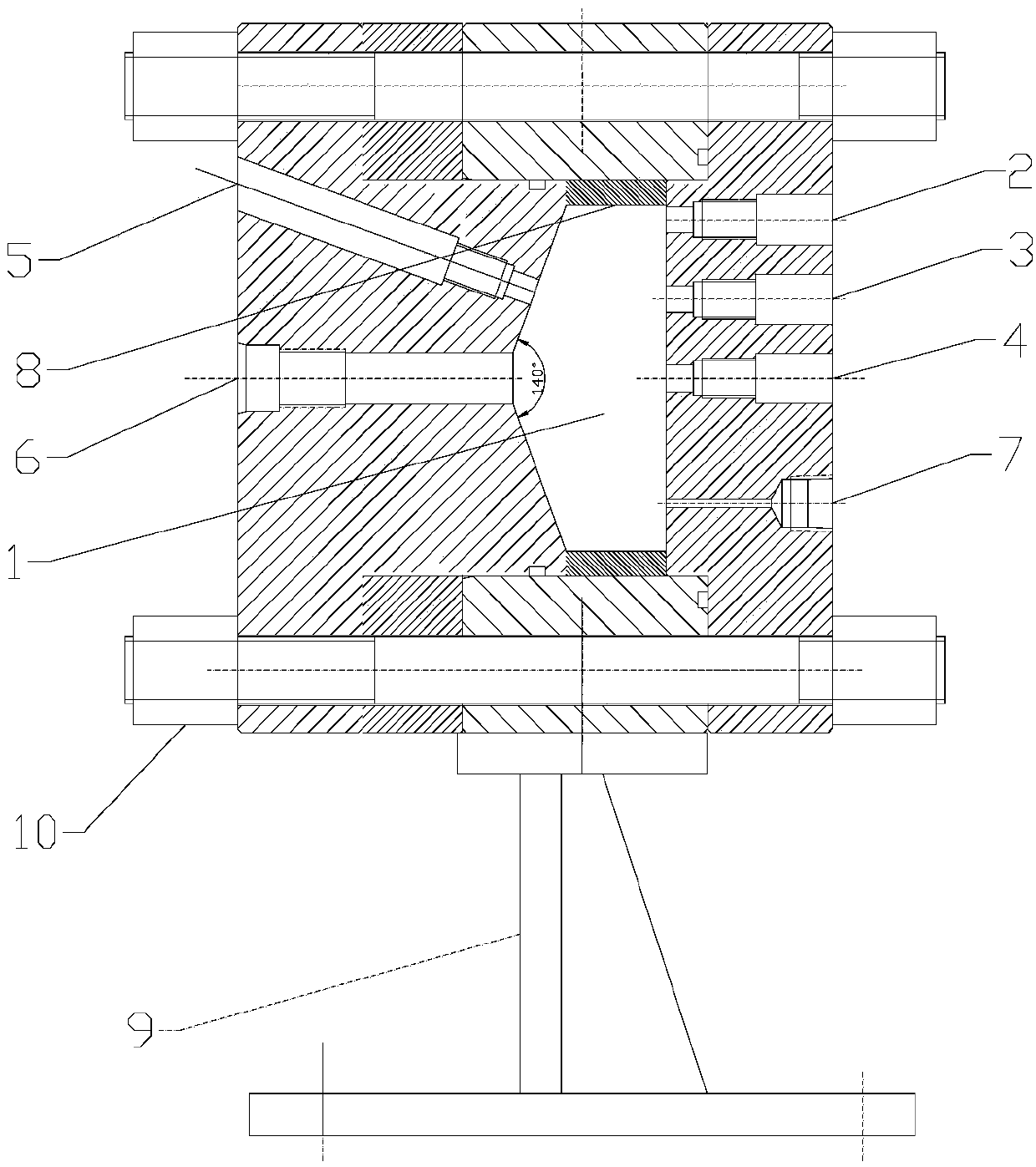

[0032] The body of the constant-volume detonation incendiary bomb has a cylinder diameter of 75-85 mm, a cone angle of 120°-180°, a cylinder head and a piston on the left and right sides, and the shapes of the cylinder head and the piston are variable; The chamber clearance is adjusted by the cylinder liner 8, variable from 0mm to 32mm; the material of the projectile body is stainless steel 1Cr18Ni9Ti, which can withstand a certain intensity of pressure; a spark plug is installed at the center of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com