Method for designing overall-width flat-inner-bottom liquid cargo ship

A design method and technology of cargo ships, applied in the direction of hull, hull parts, ship construction, etc., can solve the problems that can not completely solve the problem of anti-sediment and energy-saving, and achieve the effect of helping to remove sand, transfer loads, and improve convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

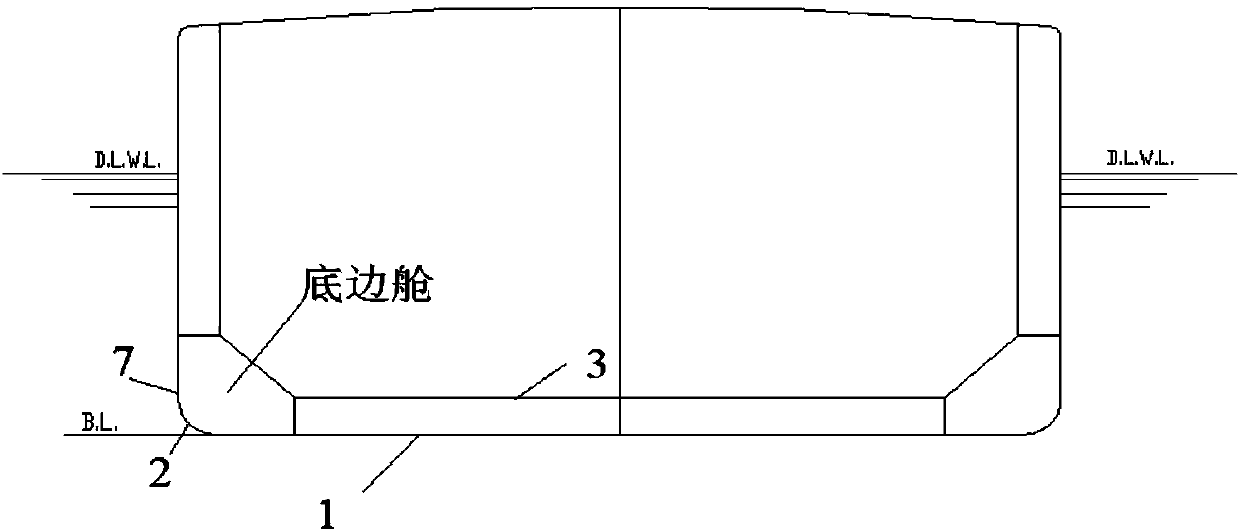

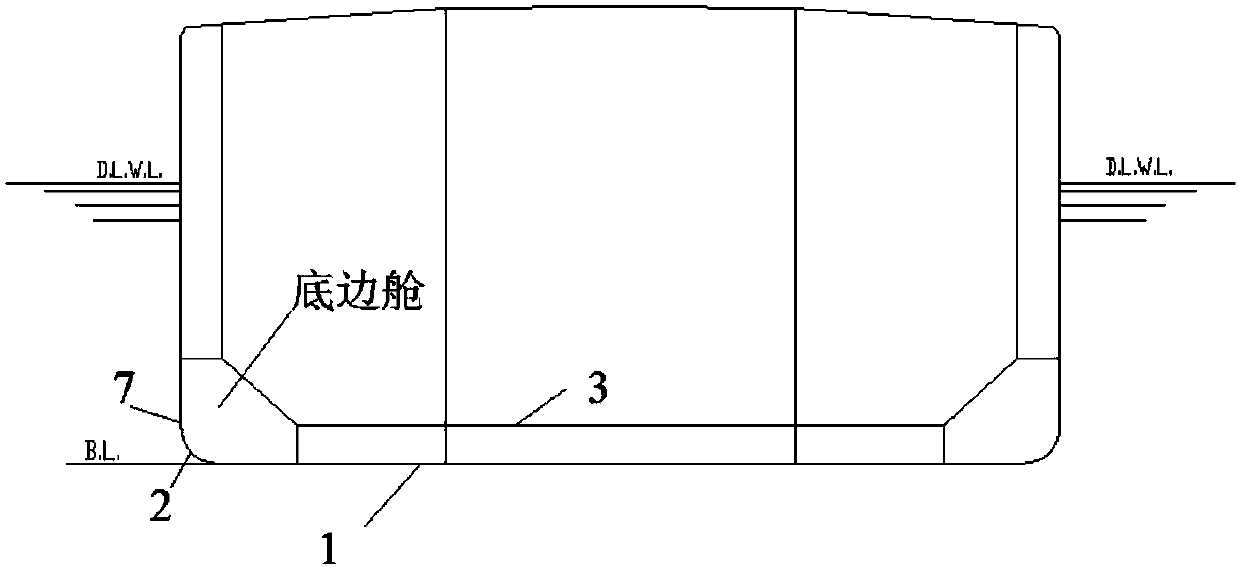

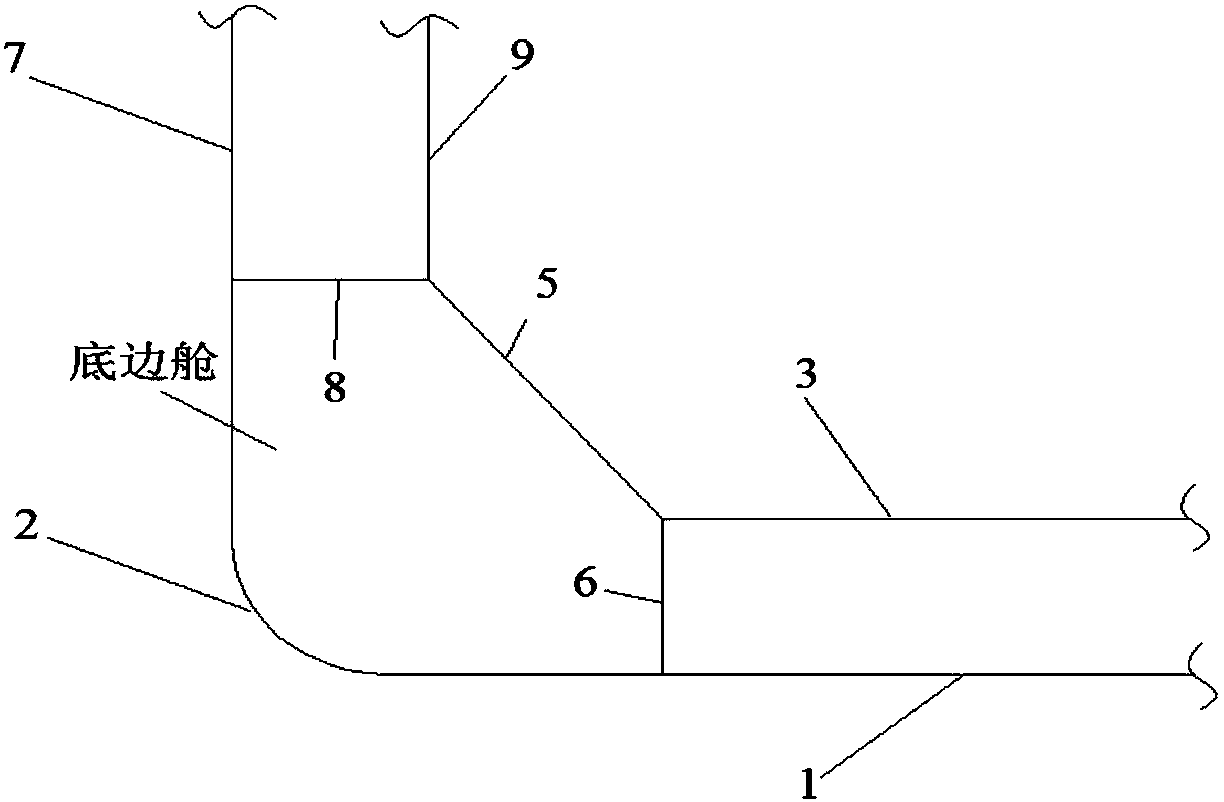

[0011] The specific implementation of the present invention will be described in detail below with reference to the technical solutions and the accompanying drawings.

[0012] In order to keep the cargo capacity of the cargo oil tank of the oil tanker unchanged and achieve the effect of sediment prevention, the bottom of the ballast tank is set as a flat inner bottom, and the area of the double bottom is set as an empty tank, thereby reducing the volume of the ballast water tank, but it must meet the Requirements of the MARPOL Convention for dedicated ballast tanks for oil tankers.

[0013] The present invention is as Figure 4 , 5 As shown in , 6, the flat inner bottom 3 is connected to the bilge 2 or the side 7 by extending the flat inner bottom 4. The characteristic is that the bottom of the ballast tank is a horizontal plate, which is not only convenient for people to walk, but also conducive to removing sediment and improving efficiency.

[0014] like Figure 4 , 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com