Rapid material removing device for tiling machine

A tile machine, fast technology, applied in the direction of supply device, ceramic forming machine, auxiliary forming equipment, etc., can solve the problems of affecting the quality of finished products and low flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

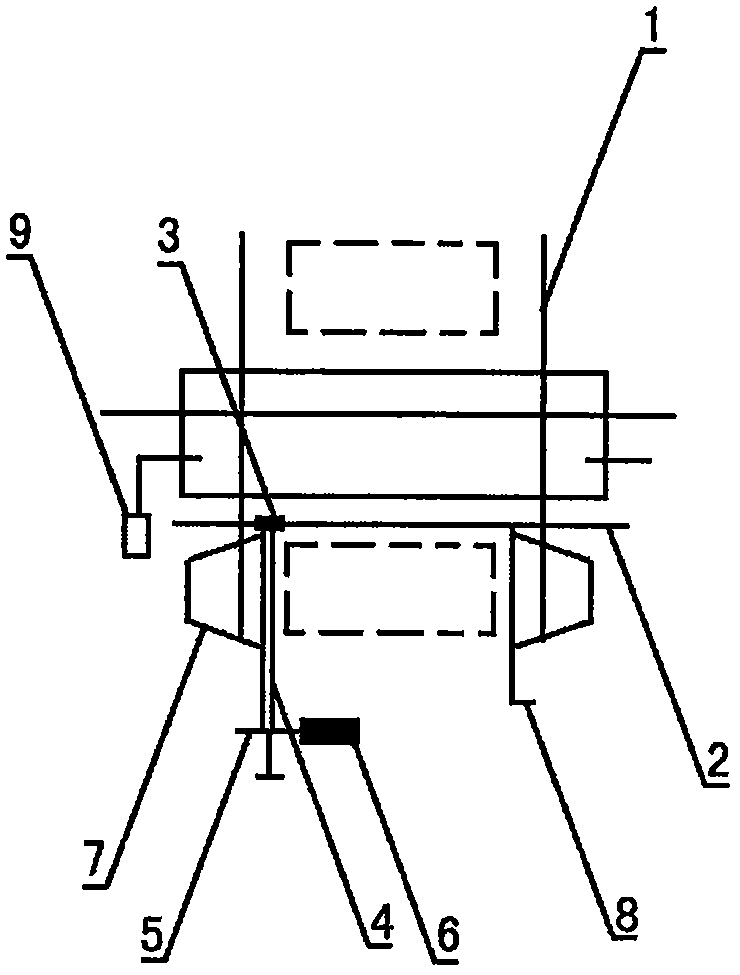

[0012] Embodiment: as shown in the accompanying drawing. A quick cleaning device for a tile machine, comprising a tile machine operating table (1), the operation table (1) is provided with a scraping structure at the front end of the die, including a laterally suspended support rod (2), a sliding device (3), a scraper Plate device (4), push handle (5), levelness monitor (6), and the blanking substrate (7) are located on both sides of the die and connected with the adjustment rod (8). Scrape the material to ensure that the water level is even.

[0013] The utility model relates to a rapid material cleaning device for a tile machine, in which a prompting device (9) is set to operate in conjunction with a levelness monitor (6), and a corresponding prompt is issued when unevenness occurs.

[0014] The utility model relates to a quick material cleaning device for a tile machine, and the information prompting method is sound or LED light display.

[0015] A quick material cleaning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com