Accurate measurement method of length of continuous casting billet

A technology for precise measurement and continuous casting, applied in the field of metallurgical continuous casting, can solve the problems of inaccurate identification and correction of the cutting length of the slab, so as to improve the measurement accuracy, reduce errors, and improve the yield of slabs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

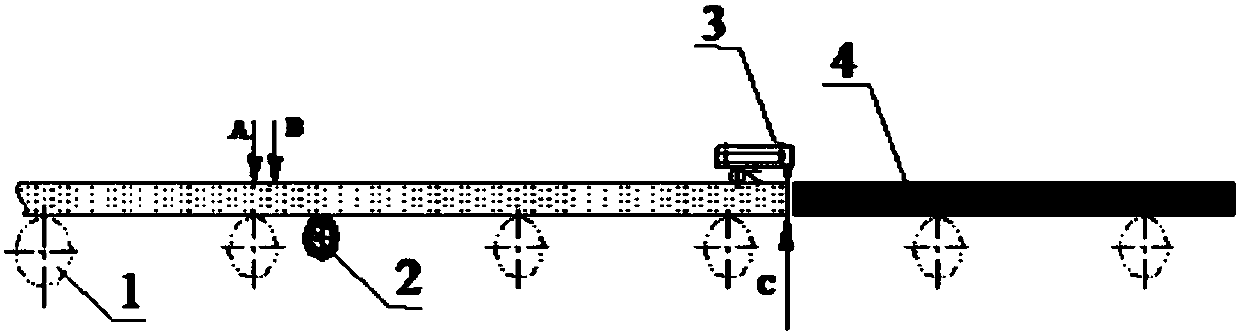

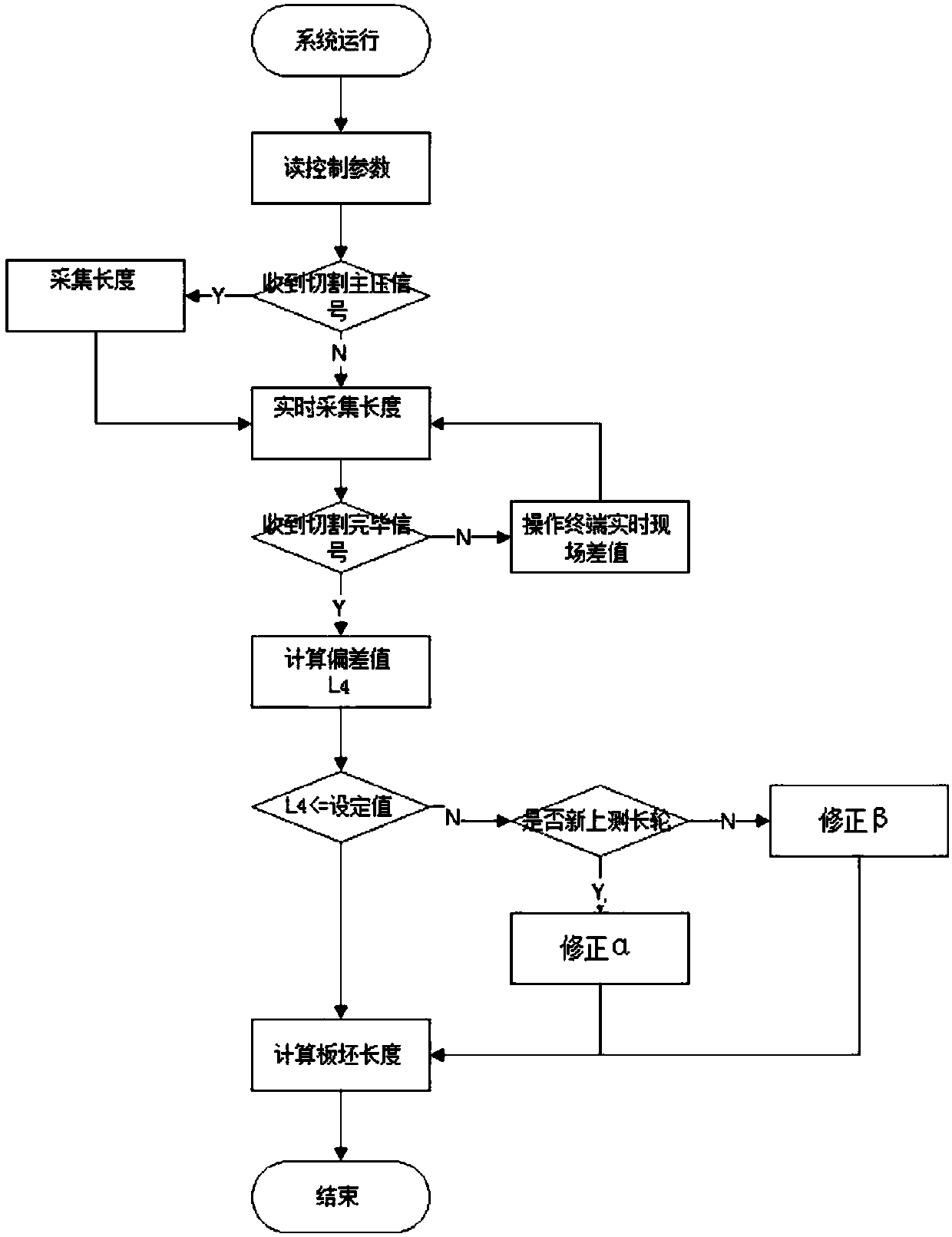

Method used

Image

Examples

Embodiment 1

[0070] When the cutting machine executes the cutting command α n =1,β n =0.9850,l 定尺 =7935mm

[0071] (1) The position detection system of the cart collects the position of the cutting machine when the slab cutting starts. 1 =8mm, the cutting machine position is S at the end of billet cutting 2 =4178mm, and calculate the walking distance S=4170mm;

[0072] (2) The slab length measurement monitoring system collects the length of the continuous casting slab at the beginning of the slab cutting as L 1 =413362mm, the length of continuous casting slab at the end of slab cutting is L 2 =417595mm, the measurement value change L=4233mm of the length measuring system of the length measuring wheel;

[0073] (3) Judgment correction module, |L-S|=|4233-4170|=63≥50, and it is confirmed that the length measuring wheel is not a standard length measuring wheel used on the new line, then correct the calculation parameters of the slab length measurement monitoring system At the end of c...

Embodiment 2

[0076] When the cutting machine executes the cutting command α n =1,β n =0.9755,l 定尺 =9526mm

[0077] (1) The position detection system of the cart collects the position of the cutting machine when the slab cutting starts. 1 =8mm, the cutting machine position is S at the end of billet cutting 2 =4178mm, and calculate the walking distance S=5720mm;

[0078] (2) The slab length measurement monitoring system collects the length of the continuous casting slab at the beginning of the slab cutting as L 1 =2215mm, the length of continuous casting slab at the end of slab cutting is L 2 =7877mm, the measurement value change L=5662mm of the length measuring system of the length measuring wheel;

[0079] (3) Judgment and correction module, |L-S|=|5662-5720|=58≥50, and it is confirmed that the length measuring wheel is the standard length measuring wheel used on the new line, then the calculation parameters of the cart position detection system are corrected At the end of cutting,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com