A feeding bottle base and its full-function glass feeding bottle

A feeding bottle and bottom surface technology, applied to feeding bottles, kitchen utensils, household utensils, etc., can solve the problems of no quick and effective method, incompleteness, inconvenient use, etc., to achieve market promotion and application, reasonable overall structure, and high economic value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below in conjunction with the drawings and embodiments:

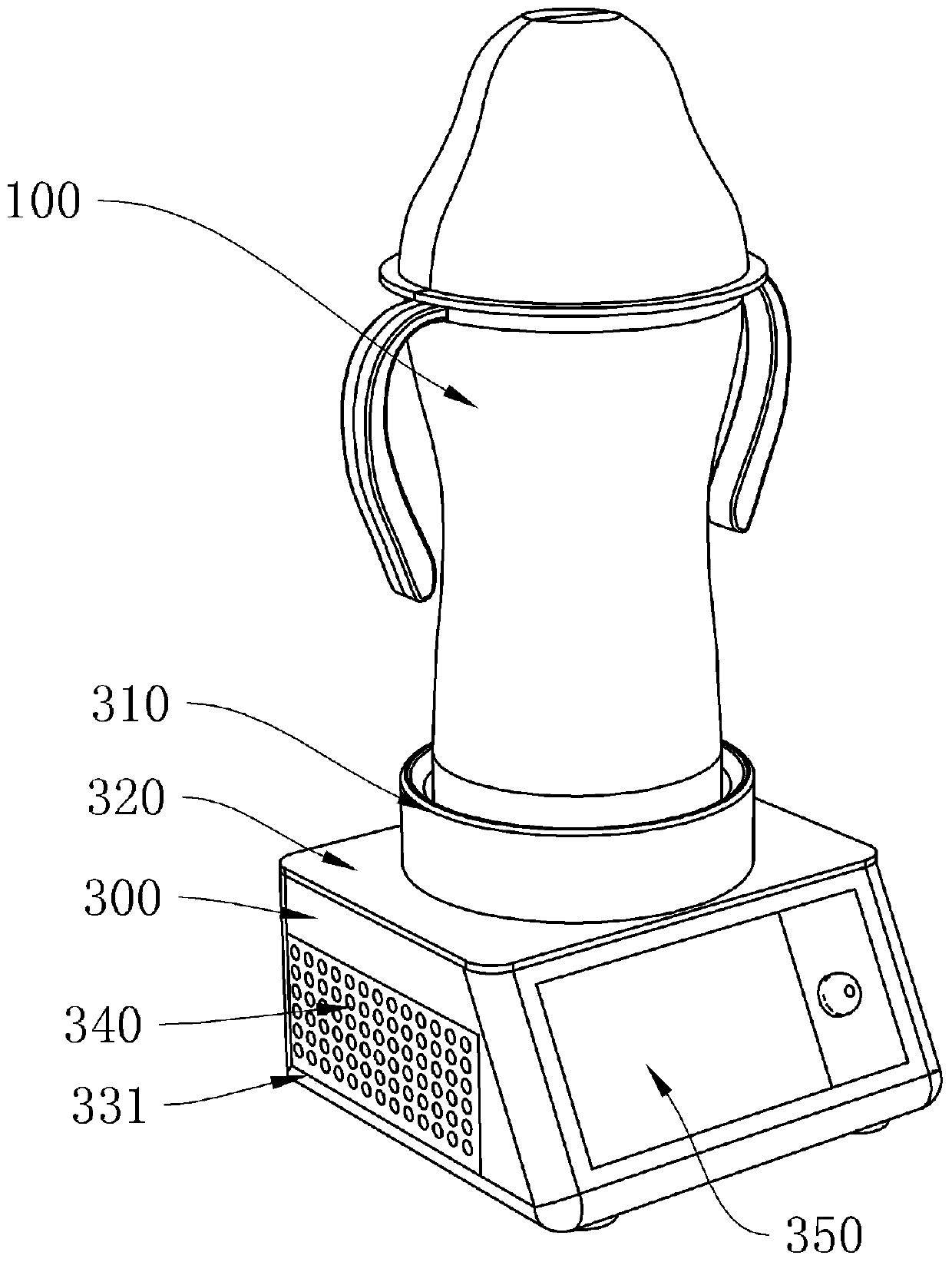

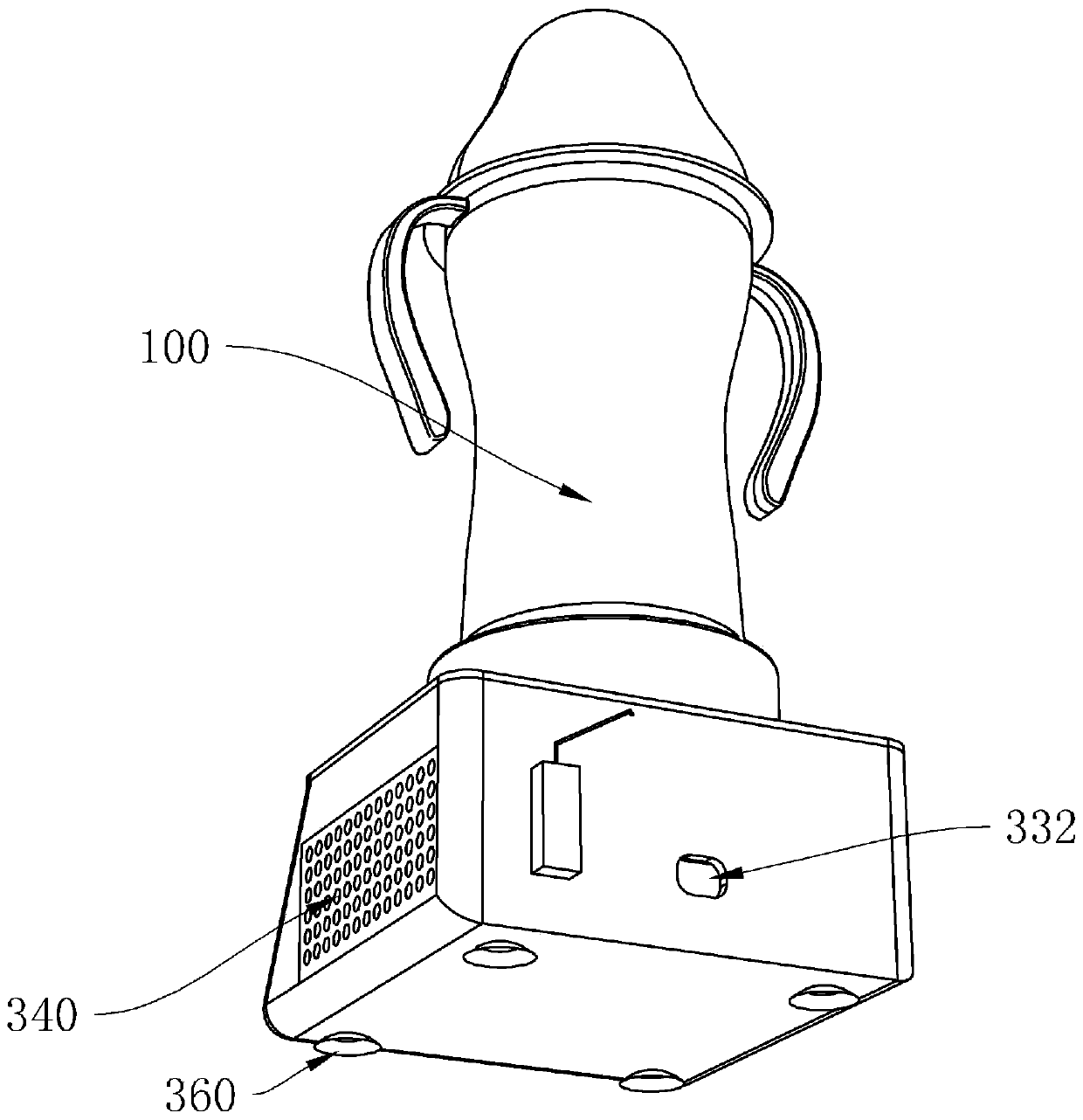

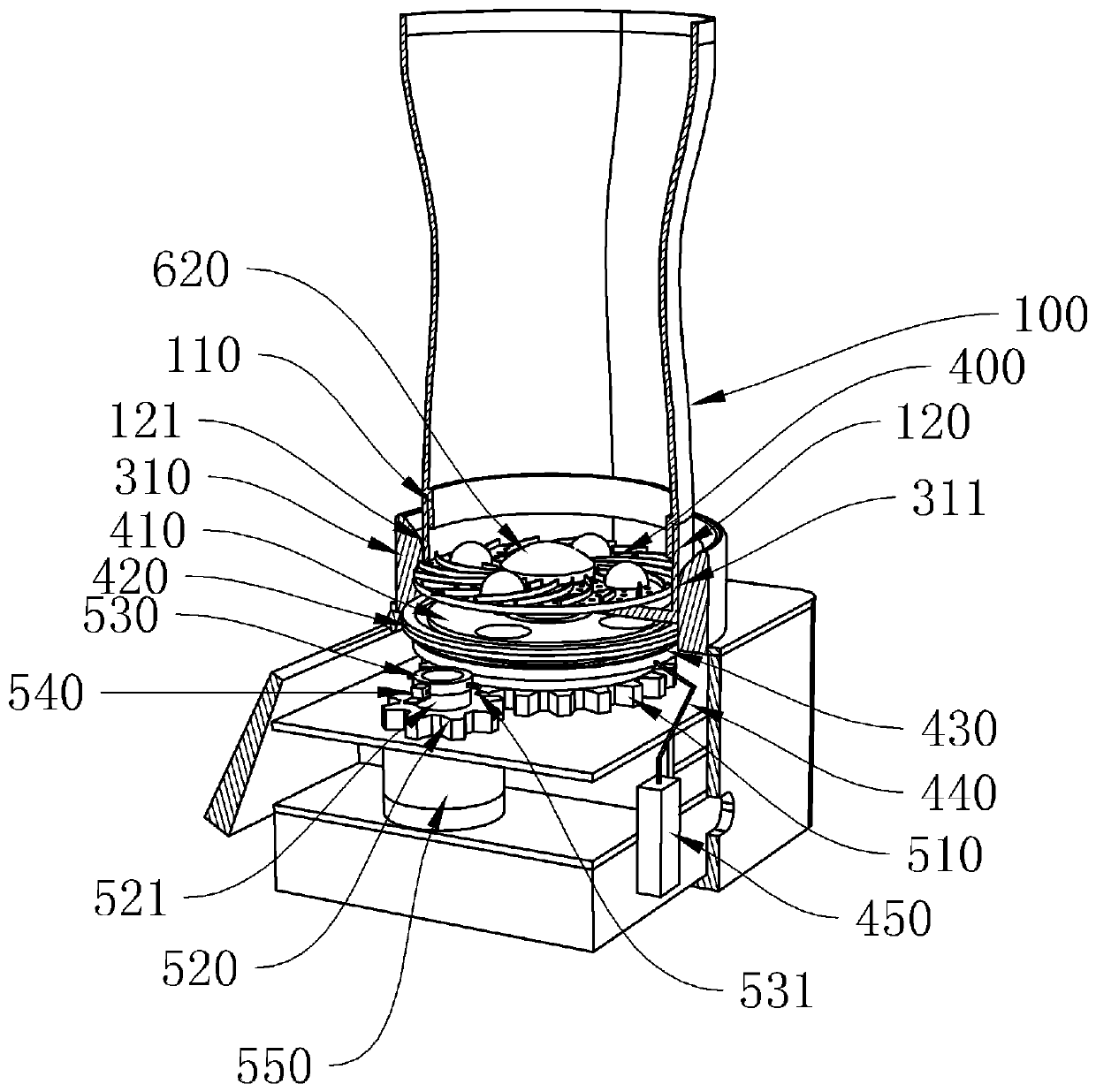

[0067] See Figure 1-Figure 11 , A full-function glass baby bottle, comprising a baby bottle body 100 and a baby bottle base 300, the bottom of the baby bottle body 100 is provided with an assembly barrel 110, and the assembly barrel 110 and the bottom cover 120 are screwed and sealed assembling;

[0068] Inside the bottom cover 120 is the bottom cover inner cylinder 121, the bottom of the bottom cover 120 is the bottom sealing plate 122, the bottom sealing plate 122 is fixed with a connecting piece 130, and the connecting piece 130 is provided with an assembly end 131 and a sealing cylinder 132, the assembly end 132 is provided with a first locking hole 133, the sealing cylinder 132 is hermetically connected with the bottom sealing plate 122, and the sealing cylinder 132 is provided with a connecting protrusion 135 inside , The first connecting groove 134 is formed bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com