Double-shooting zooming module

A camera module and module technology, applied in focusing devices, instruments, installation, etc., can solve the problems of complex manufacturing and maintenance, complex mirror tilt actuation results, and a large number of parts, so as to save manufacturing costs and labor costs , Improving the effect of image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

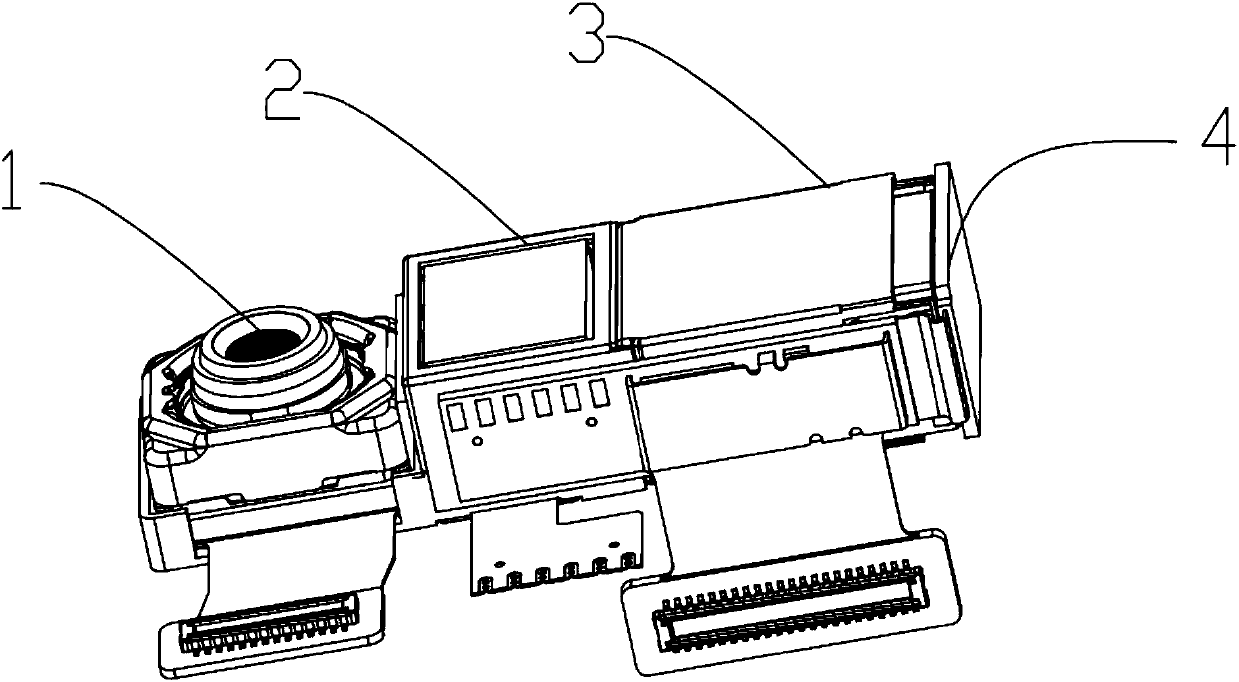

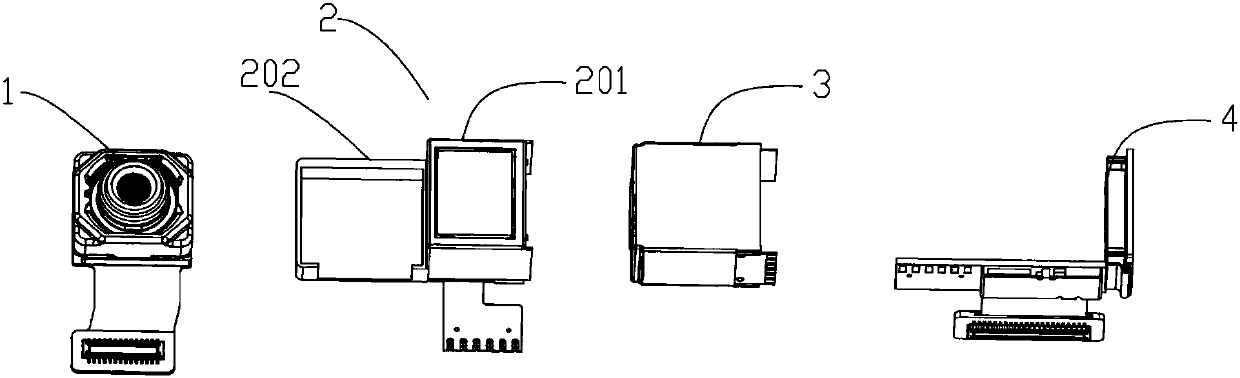

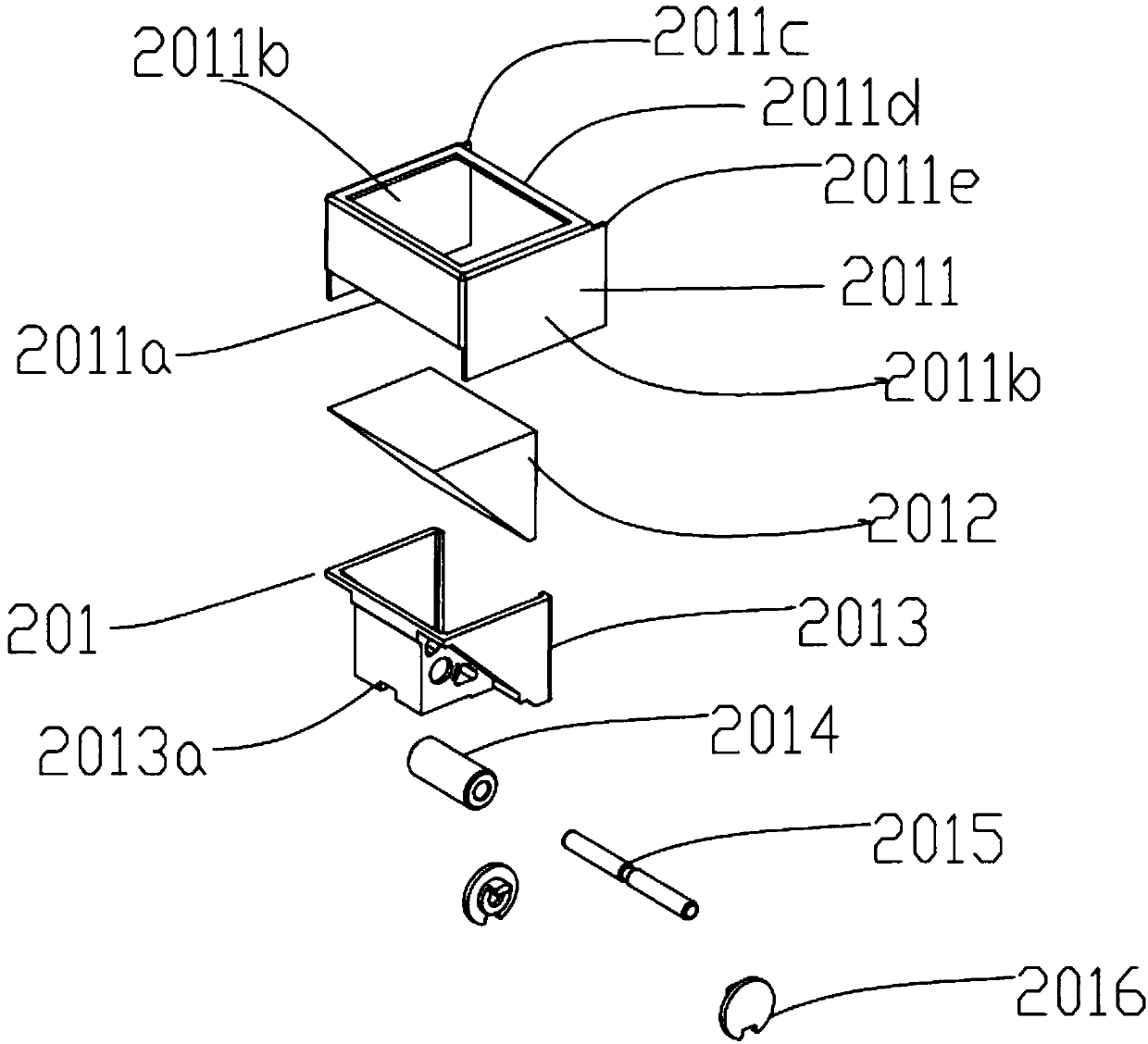

[0038] Such as figure 1 and 2 As shown, according to an embodiment of the present invention, after the first camera module 1 and the prism module 2 are assembled with each other, they are fixedly connected with the second camera module 3 . When realizing this connection, the two are required to be strictly positioned and aligned with each other. Only in this way can it be ensured that the light refracted from the prism unit 201 is concentric or coaxial with the optical axis of the camera lens in the second camera module 3 . This positioning structure will be further described in detail later in conjunction with related drawings. In this embodiment, after the prism module 2 on which the first camera module 1 is fixed and the second camera module 3 are positioned mutually, they are fixedly connected to each other by laser welding or bonding. The circuit board 4 can be pre-assembled on the second camera module 3 , and then the prism module 2 of the first camera module 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com