Menthol and peppermint oil purification process

A technology of peppermint oil and menthol, which is applied in the separation/purification of hydroxyl compounds, essential oils/flavors, and fat production, etc., can solve the problem of poor quality of broken small grains, unsatisfactory performance of crystal length and thickness, and differences in crystal shape, etc. problem to avoid errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

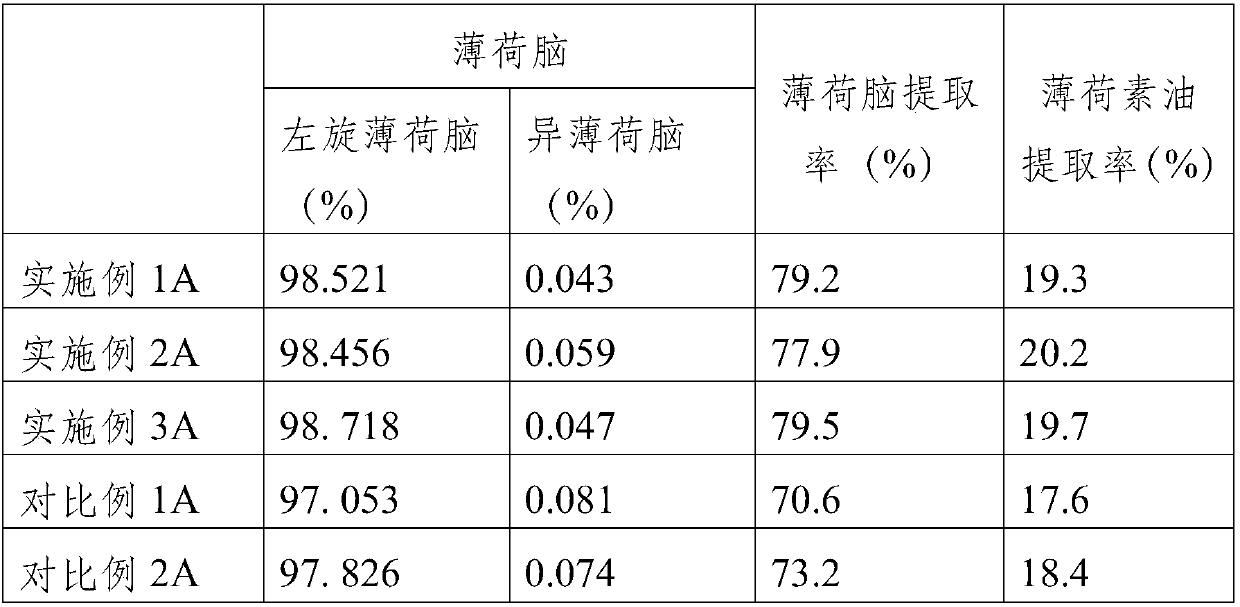

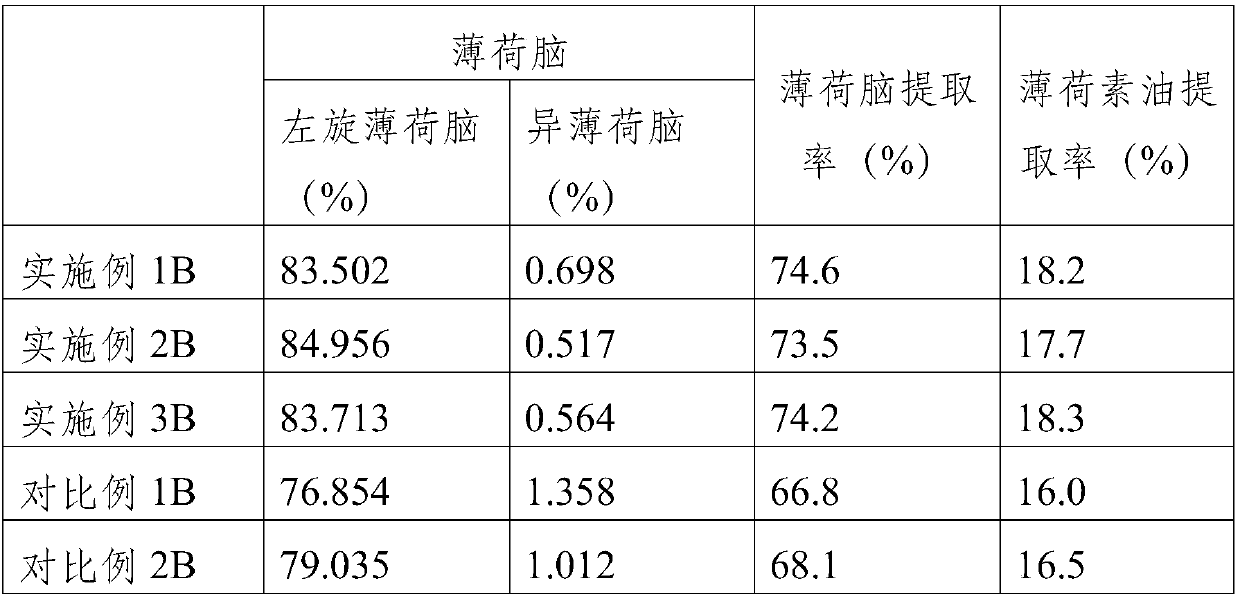

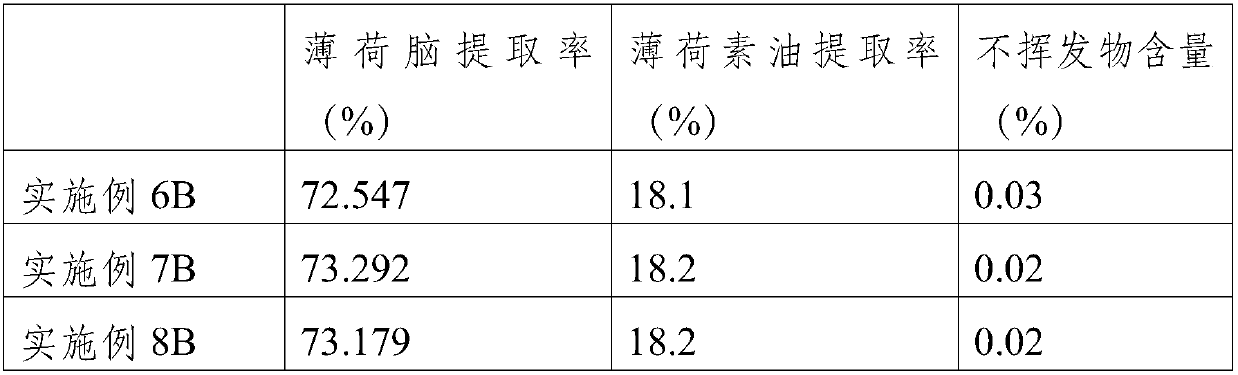

[0027] The embodiments are divided into Group A and Group B. The difference between the embodiments of Group A and the embodiments of Group B is that the origin of mint crude oil is different, and the composition is different:

[0028] The purification process of embodiment 1 is:

[0029] Embodiment 1 adopts the steps of melting, batching, dehydration, pressure filtration, brain drying, brain drying, freezing out, dehydration of hair oil and rectification steps mentioned in CN102775277A. Thermometer on the surface of the crystallization plate, and the cooling and heat preservation of the crystallization barrel is carried out alternately from the first day to the fifth day after the end of the crystallization oil feeding. From the sixth day to the 12th day, the temperature drops by 1.8°C every day when the cold salt water is turned on; from the thirteenth day to the 20th day, the temperature drops by 2.7°C every day when the cold salt water is turned on until the temperature dr...

Embodiment 2

[0041] The difference between embodiment 2 and embodiment 1 is: with the crystallization plate surface thermometer located at the lower end of the crystallization tank and built-in heat exchange pipeline, the cooling and heat preservation of the crystallization tank is carried out alternately from the first day to the fifth day after the crystallization oil feeding is completed, every day Turn on the cold brine to cool down to 25-28°C and keep it warm for 10 hours, then turn off the cold brine crystallization tank and keep it warm until the next day and turn on the cold brine again to cool down; from the sixth day to the twelfth day, the temperature drops by 2.3°C every day when the cold brine is normally on; the tenth From three days to the twentieth day, the cold brine was normally opened and the temperature dropped by 3.2°C every day until the temperature dropped to 0°C and then kept warm.

Embodiment 3

[0042] The difference between embodiment 3 and embodiment 1 is that: with the surface thermometer of the crystallization plate located at the lower end of the crystallization tank and with a built-in heat exchange pipeline, the cooling and heat preservation of the crystallization tank is carried out alternately from the first day to the fifth day after the end of the crystallization oil feeding, every day Turn on the cold brine to cool down to 25-28°C and keep it warm for 9 hours, then close the cold brine crystallization tank and keep it warm until the next day and turn on the cold brine again to cool down; from the sixth day to the twelfth day, the temperature of the cold brine will drop by 2°C every day; From three days to the twentieth day, the cold brine was normally opened and the temperature dropped by 3°C every day until the temperature dropped to 0°C and then kept warm. Among them, from the sixth day to the twelfth day, 1°C will be dropped at 8:00 am and 17:00 pm respe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crystallization point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com