Automatic non-woven bag packaging machine

A non-woven bag and packaging machine technology, applied in the field of packaging, can solve the problems of unreliable guarantee of the accuracy of the packaging quantity, no advantage of manual packaging, slow manual packaging, etc., to reduce the range of motion, small footprint, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

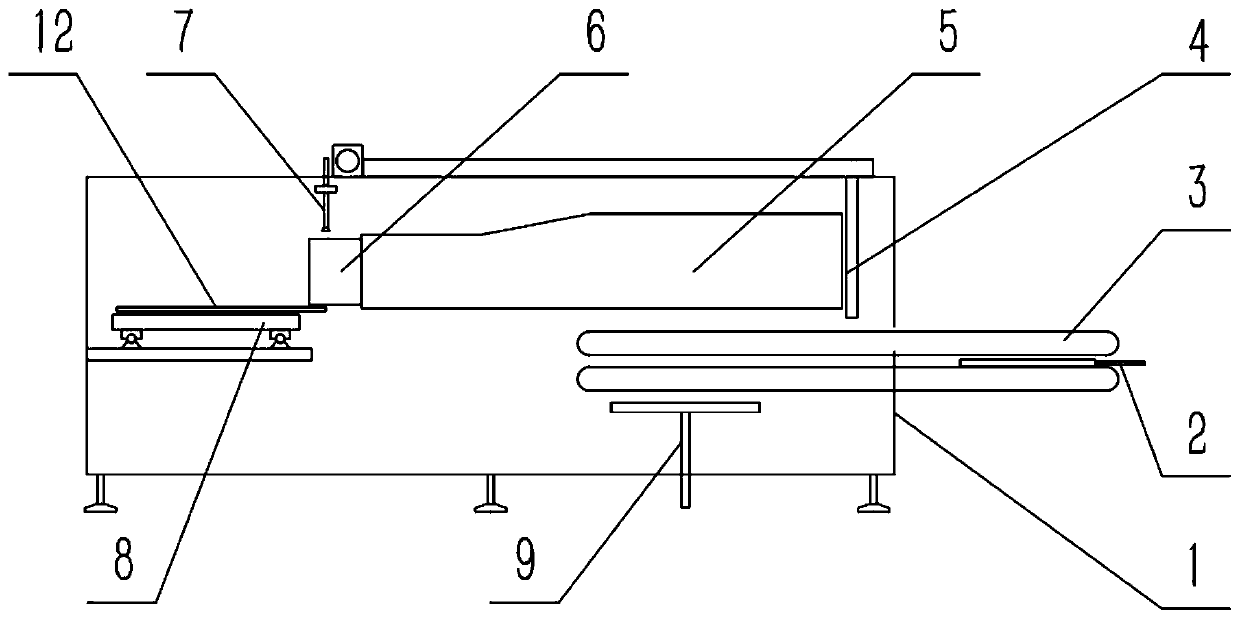

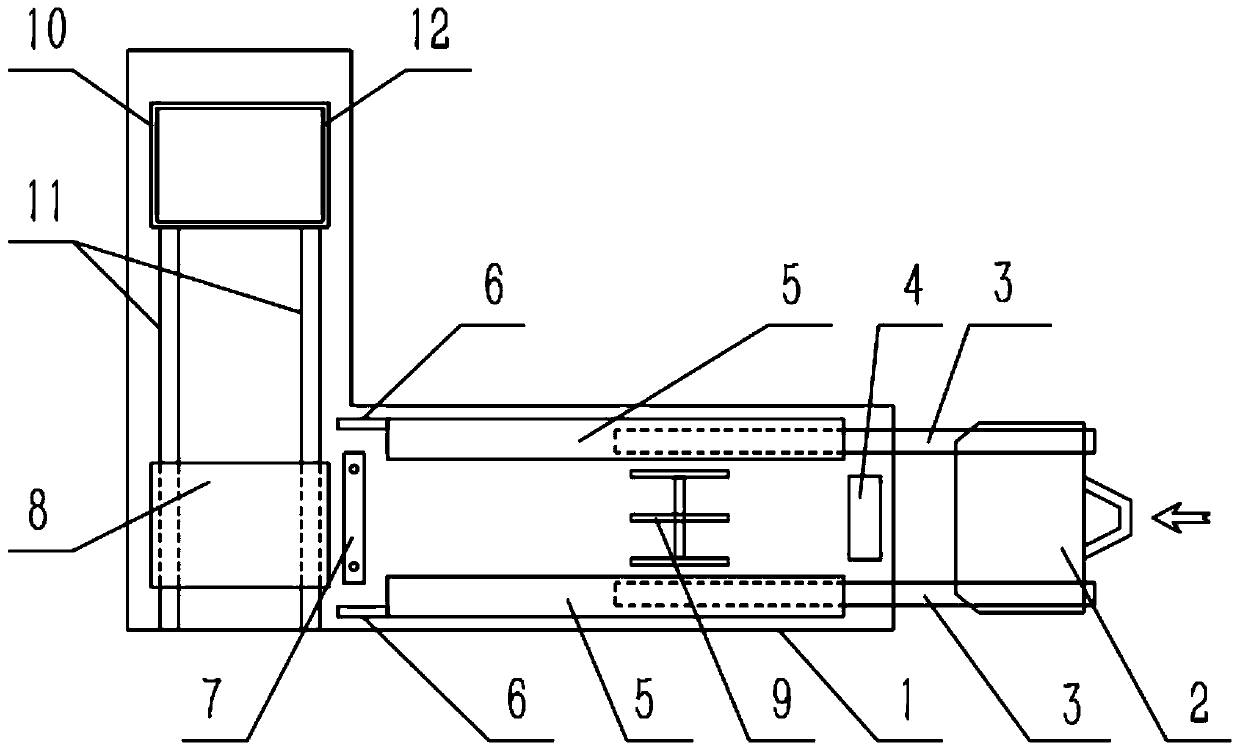

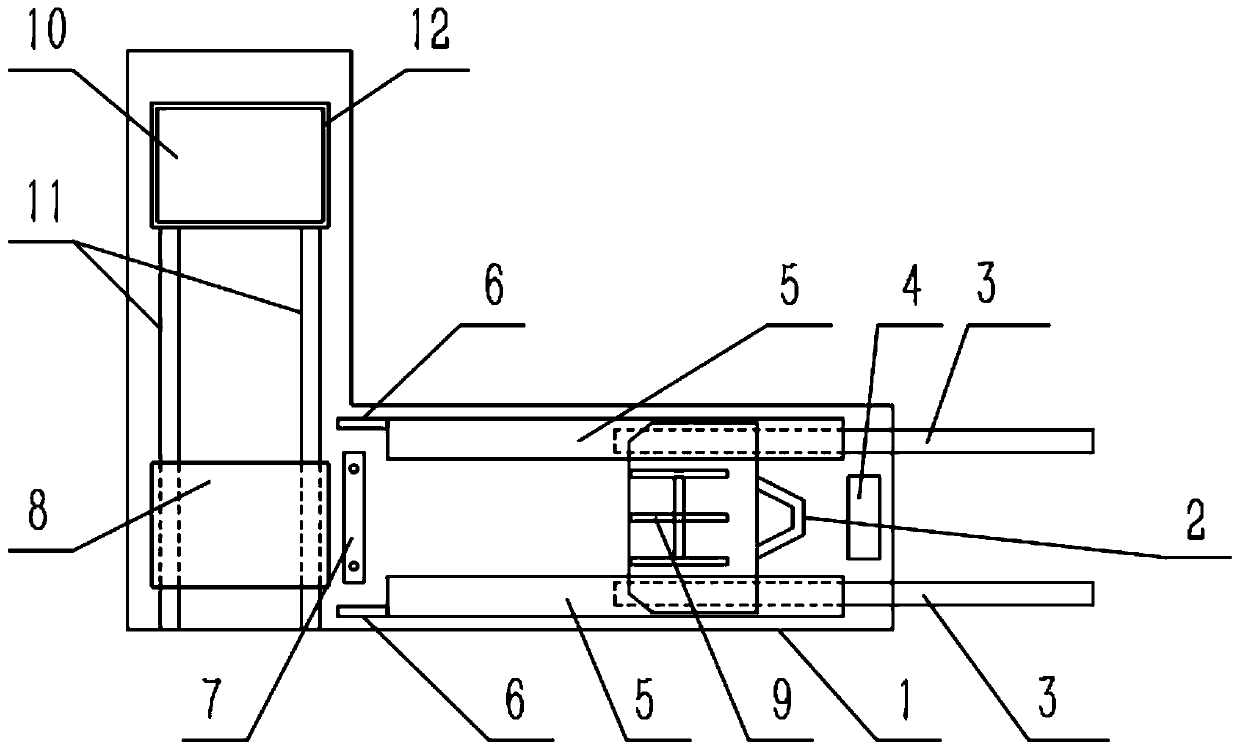

[0031] Such as Figure 1 to Figure 4 As shown, a fully automatic non-woven bag packaging machine includes a pair of conveyor belts 3 capable of conveying non-woven bags 2 one by one, a pair of parallel feed bins 5 above the conveyor belt 3, and a pair of feed bins located in two feed bins. 5 between the pusher mechanism 4, the ejector mechanism 9 positioned below the conveyer belt 3 (the ejector mechanism 9 is located between the conveyer belt 3), the packaging bag storehouse 10, the flat plate 8 with the suction cup (the sucker on the flat plate 8 is indented, does not affect the laying of the packaging bag 12), a transfer mechanism capable of transferring a single packaging bag 12 from the packaging bag bin 10 to the flat plate 8, and a liftable opening mechanism 7 with a suction cup at the outlet of the bin 5 , a pair of outwardly flipping mouthpiec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com