Control method applied to full-automatic cleaning device for welding gun of industrial arc welding robot

A technology of cleaning device and control method, applied in the direction of cleaning welding torches and welding accessories, etc., can solve the problems of poor flow of shielding gas, damage to the gun head, hidden dangers, etc., so as to reduce labor intensity, improve product quality, and eliminate the need for manual labor. effect of intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

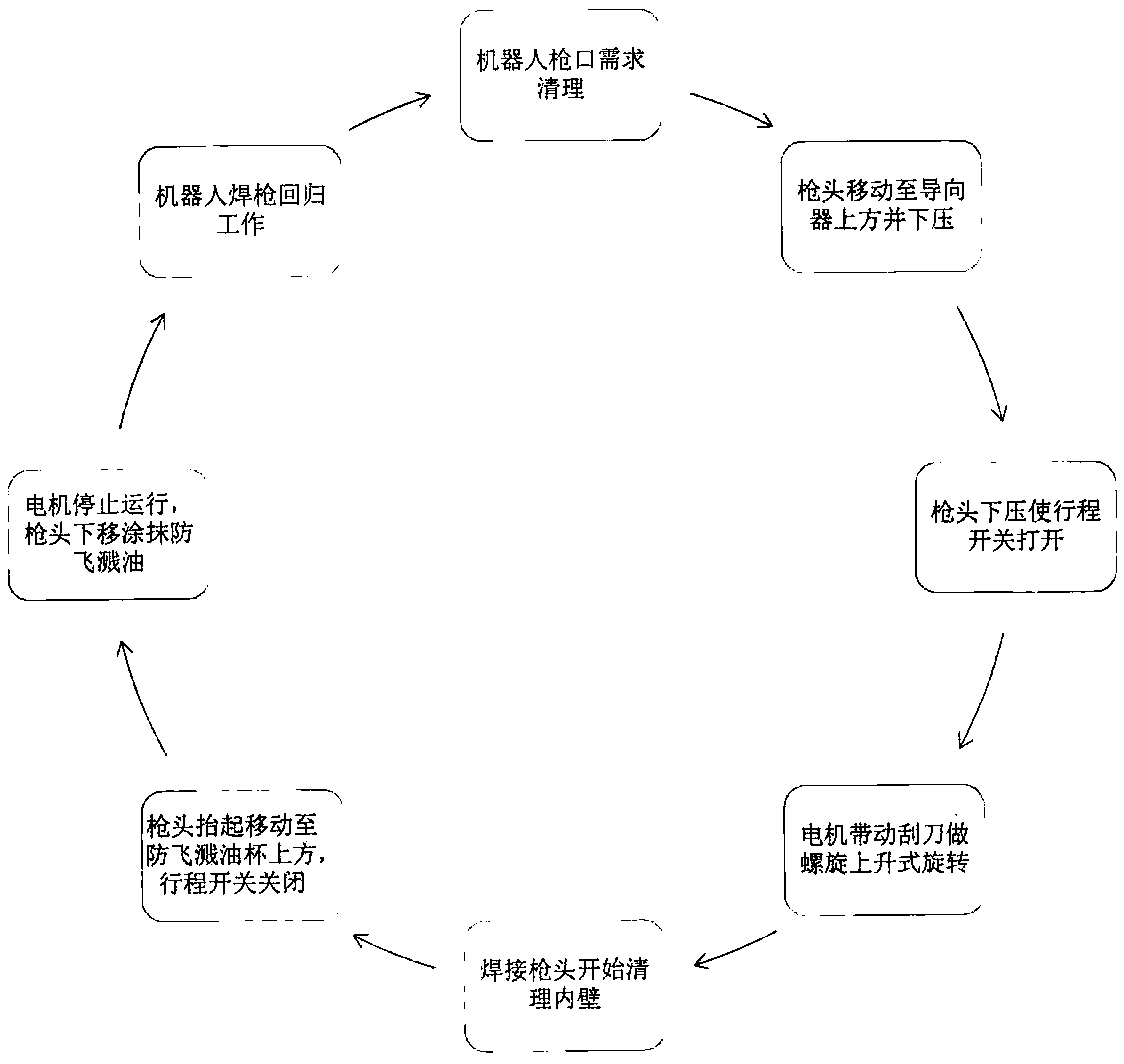

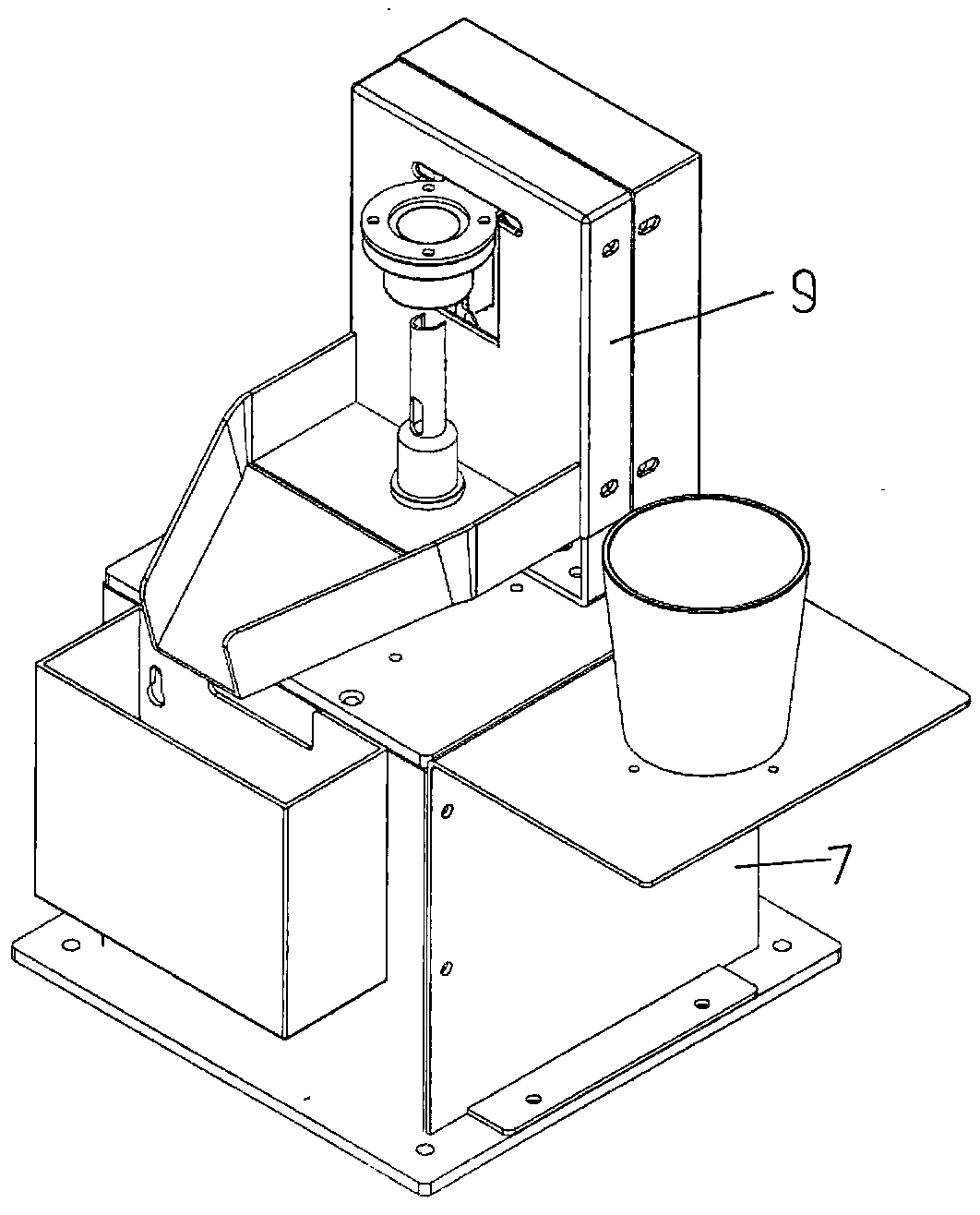

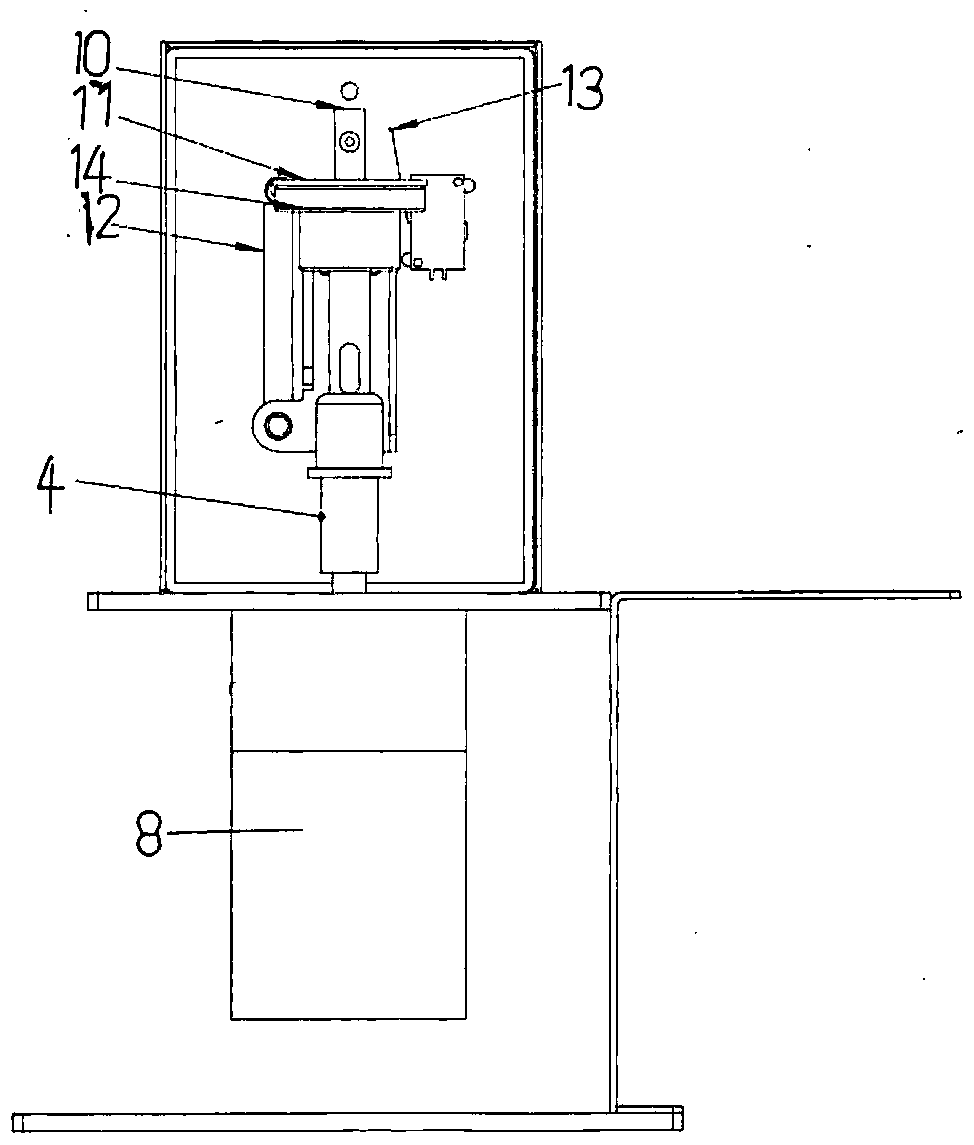

[0020] A control method applied to a fully automatic cleaning device for welding torches of industrial arc welding robots, comprising a base frame 7, a motor 8 is mounted on the base frame, a slide rail box 9 is arranged above the base frame, a slide rail 10 is mounted on the slide rail box, and a slide rail is mounted on the slide rail The slider 19 fixedly connected by the rail connector 11; the upper part of the rail connector is arranged on the upper end of the guide, and is fixedly connected with the upper end of the guide, and the central center hole of the rail connector and the central center hole of the guide are on the same axis , the bottom of the slide rail connector extends below the guide, the lower end of the spring 12 is fixedly connected with the bottom of the slide rail connector, and the upper end of the spring is fixedly connected with the slide rail box; The stroke switch 13 of motor work. The scraper includes a cutter head 1, the cutter head is in the for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com