Pulverizer provided with shock absorber

A milling machine and shock absorber technology, applied in the field of milling machines, can solve problems such as poor milling quality, unreasonable structural design, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

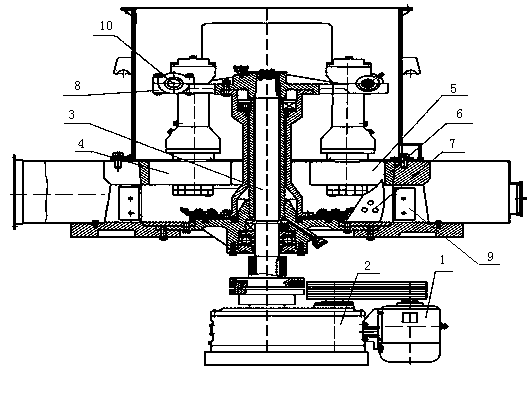

[0011] Such as figure 1 As shown, a mill with a shock absorber includes a main motor 1 of the mill and a reducer 2 arranged on one side of the main motor 1 of the mill. Machine central axis 3, the horizontal direction on the central axis 3 of the mill is provided with a grinding roller device 4, and the grinding roller device 4 is provided with a grinding roller 5, a grinding ring 6, a spatula 7 and a shock absorber 9, On both sides of the upper end of the central shaft 3 of the mill, at least one plum blossom frame 8 is respectively provided, and a grinding roller assembly 10 is arranged on the horizontal direction of the plum blossom frame 8 .

[0012] There is at least one shock absorber 9 . The reducer 2 is a multi-stage adjustable reducer.

[0013] Any design using similar technical features as the present invention will fall within the protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com