Mechanism for automatically loading motor magnetic steel sheets

A technology of automatic loading and magnetic steel sheets, which is applied in the direction of electromechanical devices, electric components, and manufacturing motor generators, etc., can solve the problems of low production efficiency, unfavorable production, labor consumption, etc., and achieve easy control operation, improve production efficiency, and save energy. labor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

[0024] The rotor core 4 referred to in the present invention comprises a magnetic steel slot 41 and an iron core shaft hole 42 (such as Figure 6 shown).

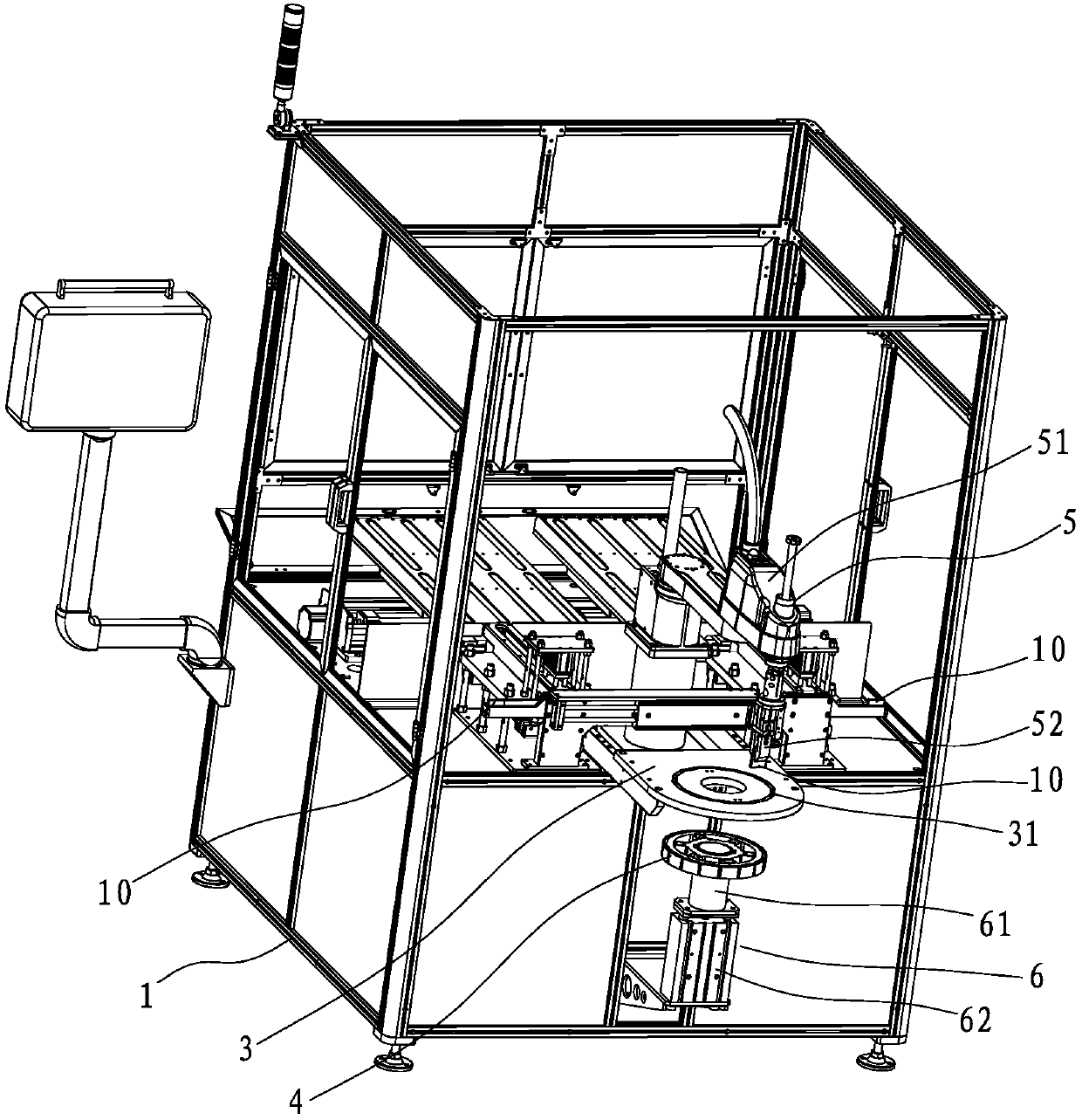

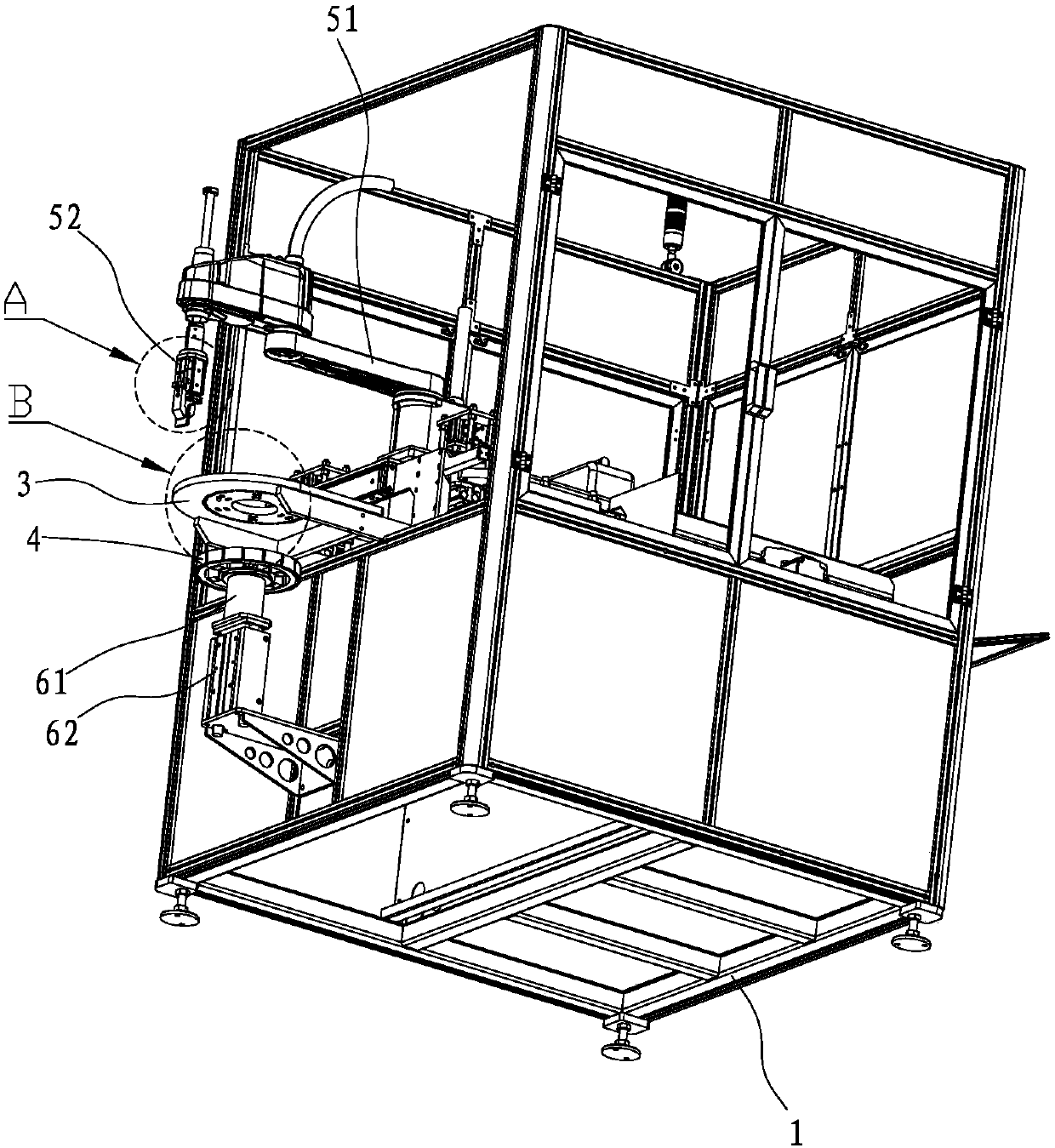

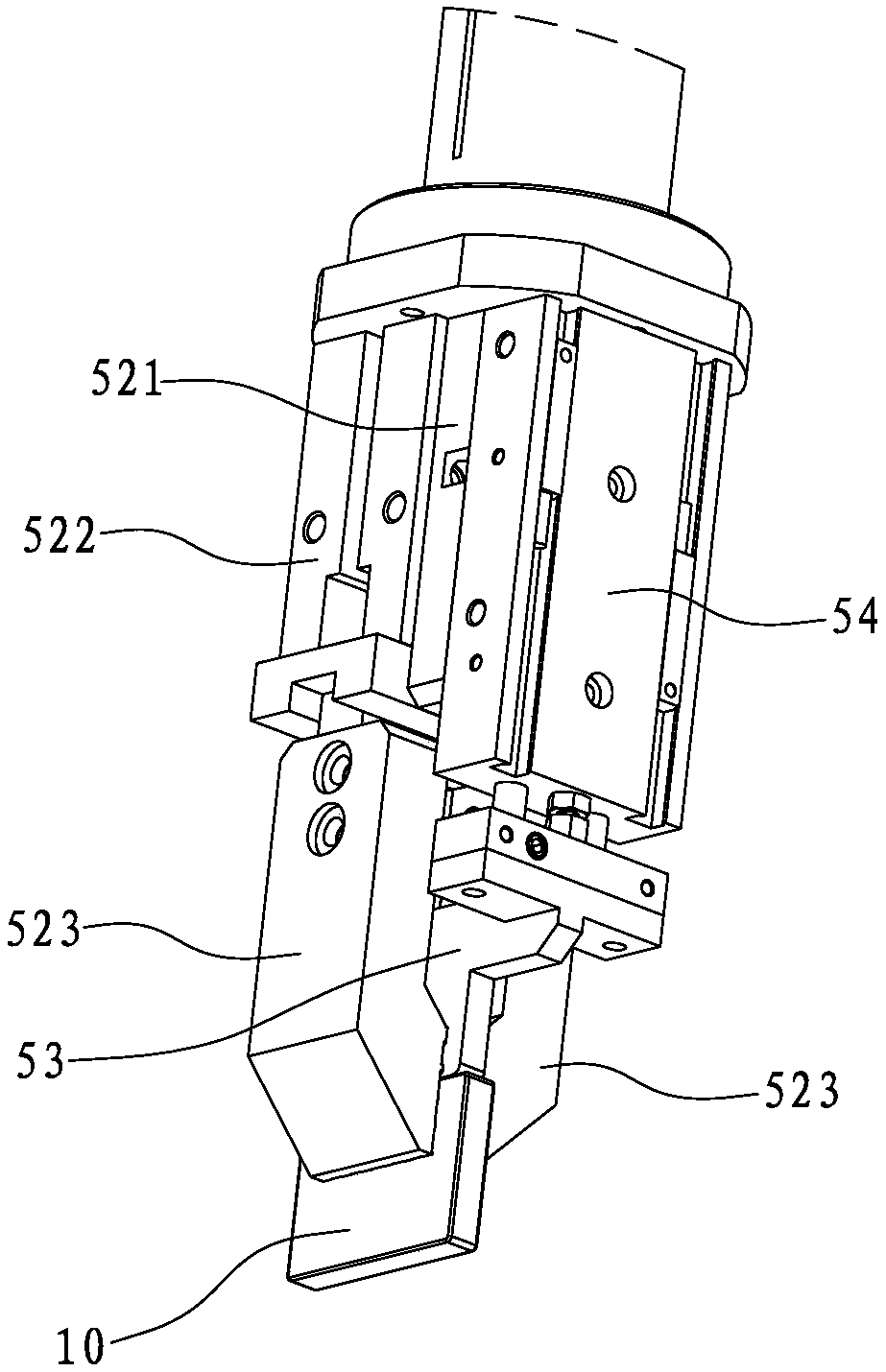

[0025] Such as Figure 1 to Figure 5 The shown automatic loading mechanism for a magnetic steel sheet of a motor includes a frame 1, a guide plate 3 is provided on the frame 1, and a rotor core 4 for positioning the rotor core 4 is provided below the guide plate 3 and can automatically The jacking assembly 6 that lifts the rotor core 4 toward the guide plate 3, the guide plate 3 is provided with a guide groove 31 corresponding to the magnetic steel groove 41 of the rotor core and for the magnetic steel sheet 10 to pass through. The frame 1 is provided with a manipulator device 5 capable of clamping the magnetic steel sheet 10 into the guide groove 31 during operation so that the magnetic steel sheet 10 enters the magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com