A kind of in situ implanted polymer particle solid electrolyte and preparation method thereof

A solid electrolyte and polymer technology, applied in solid electrolyte, electrolyte battery manufacturing, non-aqueous electrolyte and other directions, to achieve the effect of less difficulty in industrialization, excellent performance and huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

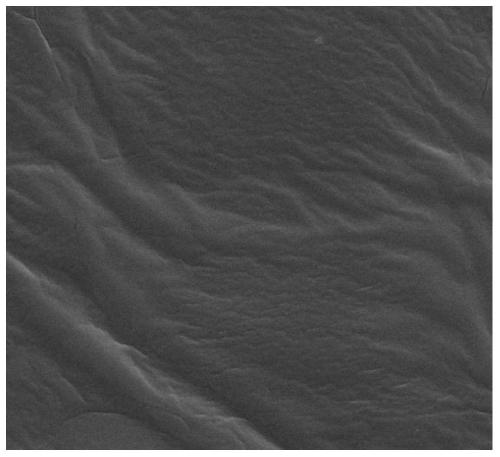

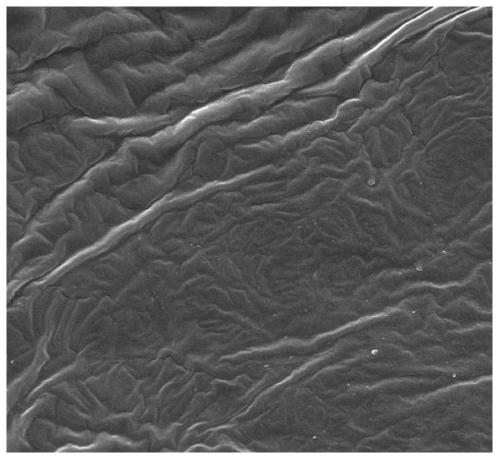

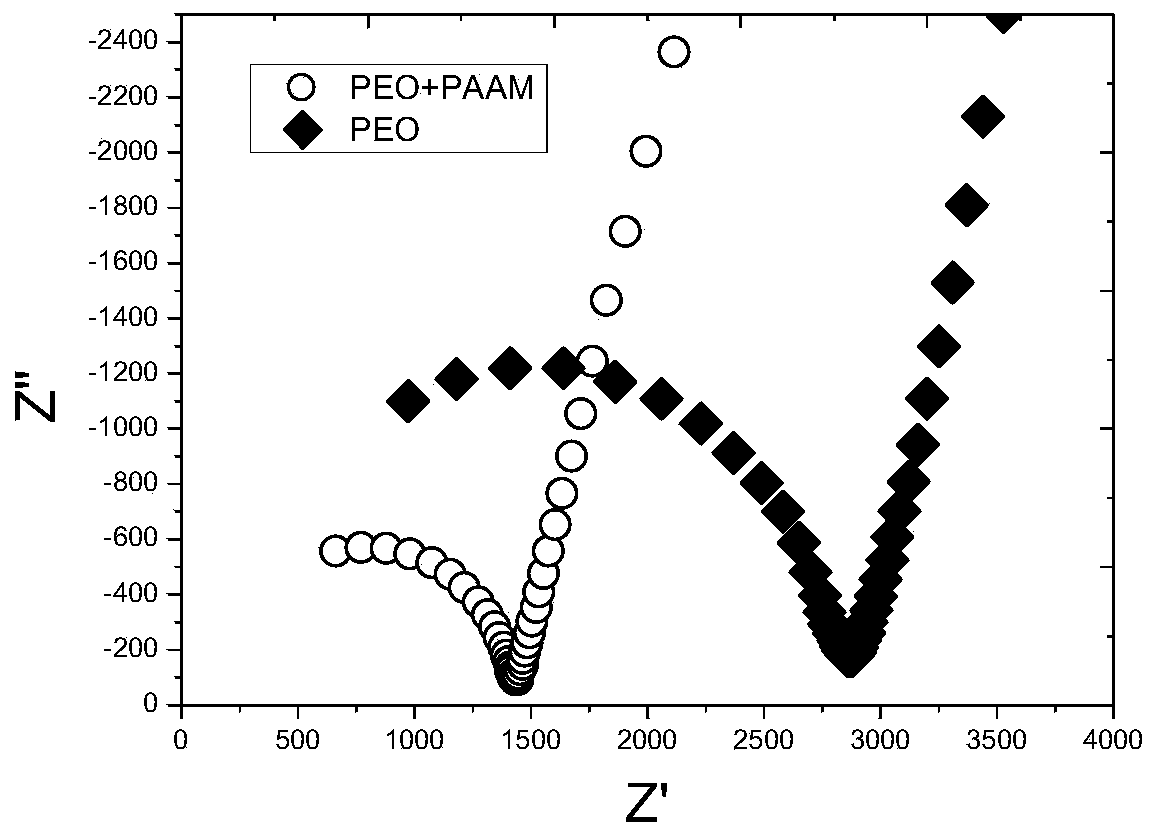

Image

Examples

Embodiment 1

[0035] A preparation method for in-situ implantation of polymer particle solid electrolyte, comprising the following steps:

[0036] (1) In an argon glove box, 25 parts of lithium salt bistrifluoromethanesulfonimide lithium soluble in polyethylene oxide and 60 parts of polyethylene oxide are added to the container, and anhydrous acetonitrile is added to stir and dissolve to obtain transparent or Translucent solution; solvent anhydrous acetonitrile water content less than 40PPm, oxygen less than 50ppm. The total weight of lithium salt and polyethylene oxide added: anhydrous acetonitrile = 1 g: 50 mL. The stirring temperature of polyethylene oxide and lithium salt in acetonitrile is 22 degrees centigrade, and the process of adding lithium salt controls the water content to be less than 40 ppm.

[0037] (2) Add 5 parts of acrylamide, 0.01 part of crosslinking agent, and 0.01 part of initiator to the solution; the crosslinking agent is NN-methylenebisacrylamide, and the initiator...

Embodiment 2

[0041] A preparation method for in-situ implantation of polymer particle solid electrolyte, comprising the following steps:

[0042] (1) In a nitrogen glove box, 30 parts of lithium trifluoromethanesulfonimide lithium soluble in polyethylene oxide and 65 parts of polyethylene oxide are added to the container, and anhydrous acetonitrile is added to stir and dissolve to obtain transparent or translucent Solution; solvent anhydrous acetonitrile water content is less than 40PPm, oxygen is less than 50ppm. The total weight of the added lithium salt and polyethylene oxide: anhydrous acetonitrile = 1 g: 60 mL. The stirring temperature of polyethylene oxide and lithium salt in acetonitrile is 24 degrees Celsius, and the process of adding lithium salt controls the water content to be less than 40ppm.

[0043] (2) Add 10 parts of acrylamide, 0.03 parts of cross-linking agent, and 0.03 parts of initiator to the solution; the cross-linking agent is divinylbenzene, dicumyl peroxide, and t...

Embodiment 3

[0047] A preparation method for in-situ implantation of polymer particle solid electrolyte, comprising the following steps:

[0048] (1) In an argon or nitrogen glove box, add 35 parts of lithium salt soluble in polyethylene oxide and 70 parts of polyethylene oxide into the container, add anhydrous acetonitrile and stir to dissolve to obtain a transparent or translucent solution; the solvent is anhydrous The water content in acetonitrile is less than 40ppm, and the oxygen content is less than 50ppm. The lithium salt is lithium bistrifluoromethanesulfonylimide and lithium trifluoromethanesulfonylimide. The total weight of the added lithium salt and polyethylene oxide: anhydrous acetonitrile = 1 g: 70 mL. The stirring temperature of polyethylene oxide and lithium salt in acetonitrile is 26 degrees centigrade, and the process of adding lithium salt controls the moisture content to less than 40 ppm.

[0049] (2) Add 20 parts of acrylamide, 0.05 parts of a crosslinking agent, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com