Preparation method of high-power and long-life cathode heater assembly

A long-life, high-power technology, applied in cold cathode manufacturing, thermal electron cathode manufacturing, electrode system manufacturing, etc., can solve the problems of no improvement and improvement, and achieve the effects of shortened start-up time, uniform temperature distribution, and firm fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

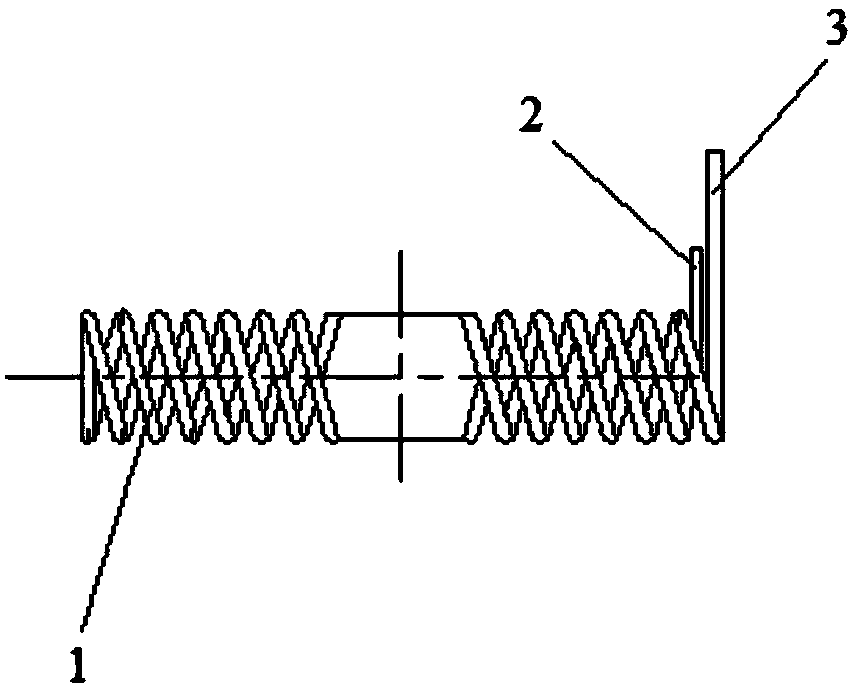

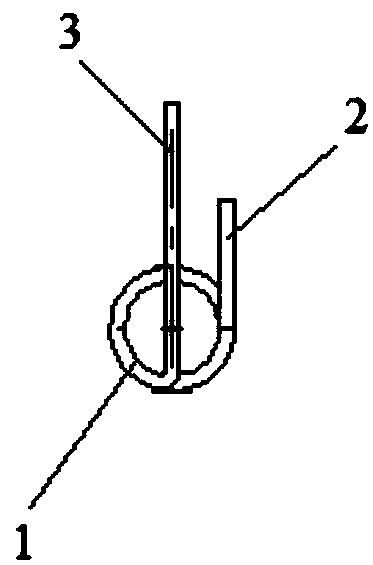

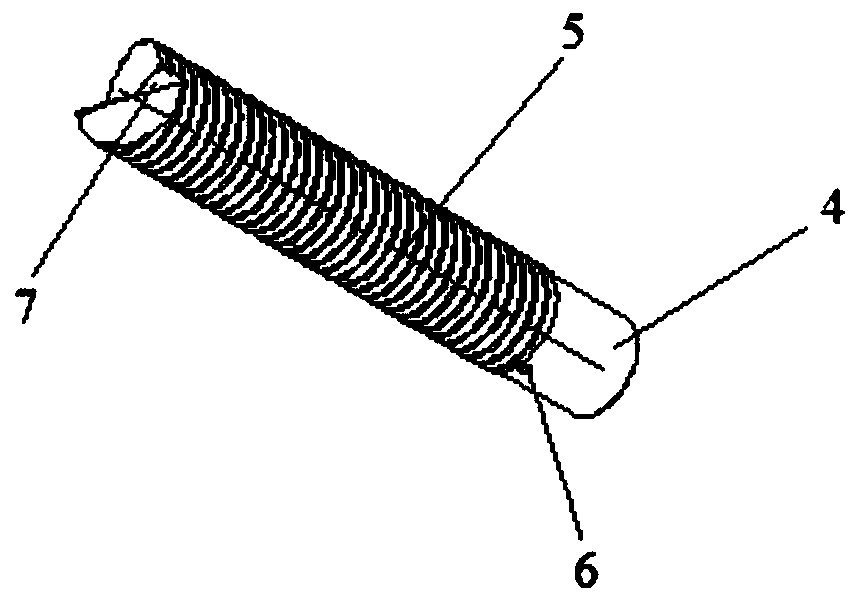

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0031] The preparation method of the high-power and long-life cathode heater assembly in this embodiment includes the following steps:

[0032] 1) In order to improve the mechanical strength of the heating wire, choose a rhenium tungsten wire with a diameter of 0.90-0.95mm (preferably 0.92mm). Compared with tungsten wire, rhenium tungsten wire has higher resistivity and better ductility Well, the recrystallization temperature should be as high as 150-200°C; and its tensile strength is several times higher than that of pure tungsten wire, and its interaction with alumina coating is weak; in high-power vacuum electronic devices, due to the effect of strong magnetic field , Excessive initial current, due to the influence of mechanical force, may cause the welding spot of the hot wire to be soldered or fall off. Therefore, in high-power v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com