Novel pure-oxygen metal burner

A metal and pure oxygen technology, applied in the field of metal burners and new pure oxygen metal burners, can solve the problems of shortened service life of burners, economic loss of heat-resistant castables and corundum bricks, ablation of burner heads, etc., to achieve The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail below in conjunction with accompanying drawing:

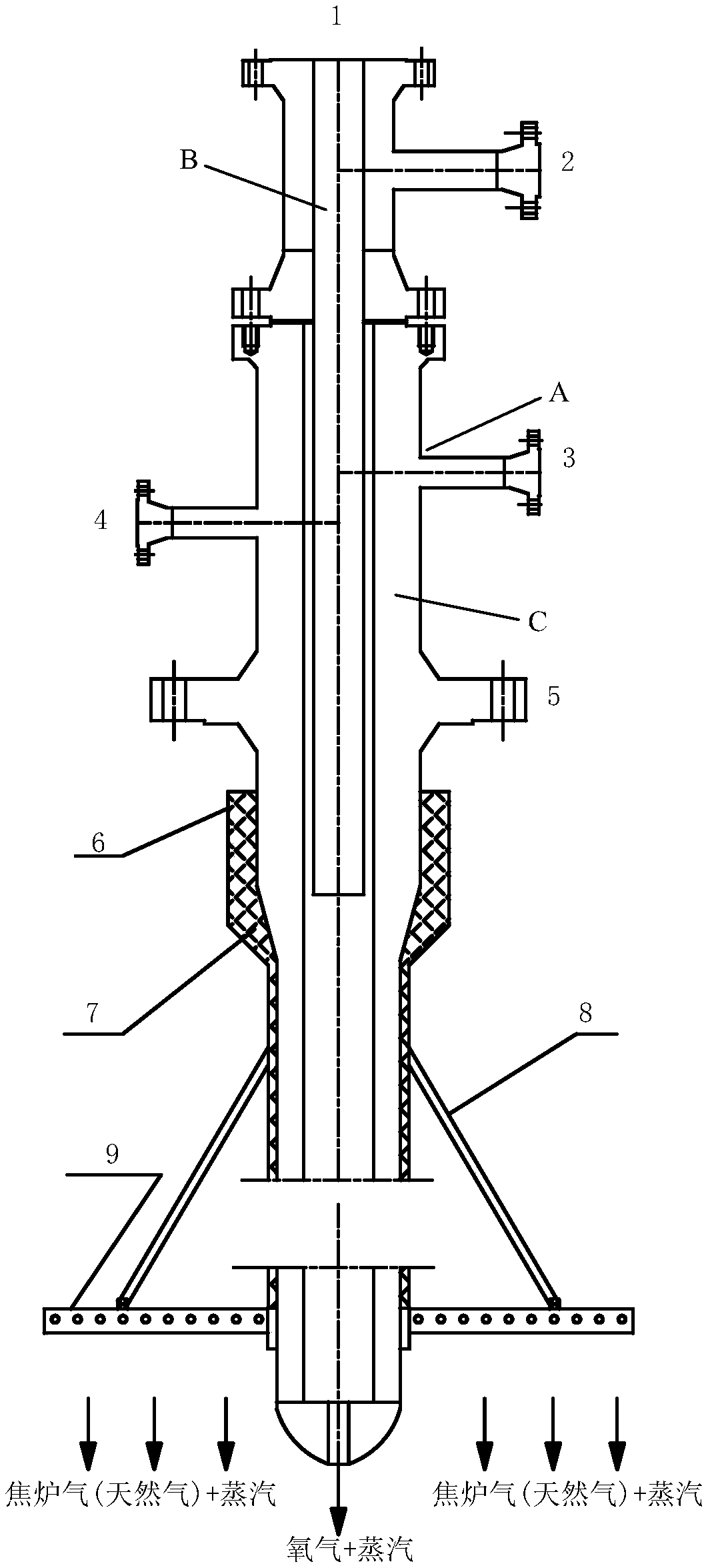

[0020] see figure 1 : Novel pure oxygen metal burner of the present invention, comprises metal burner body A, is provided with oxygen and steam channel B in metal burner body A, is provided with for whole oxygen and steam channel B cooling outside oxygen and steam channel B The cooling water channel C; the outer wall of the lower part of the metal burner body A close to the burner head is provided with a high temperature resistant protective sleeve structure; the upper outer wall of the metal burner body A is located at the entrance of the oxygen and steam channel B A protective steam inlet 2 is provided nearby.

[0021] The high temperature resistant protective sheath structure of the present invention includes a protective sleeve 6 and heat insulating cotton 7 arranged between the protective sleeve 6 and the outer wall of the metal burner body A.

[0022] The cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com