System for discharging sludge at upper layer of floatation tank

An air flotation tank and mud slag technology, applied in flotation water/sewage treatment and other directions, can solve the problems of affecting the effluent quality, the mud layer cannot be removed with the diversion weir, affecting the effluent quality of the air flotation tank, etc., and achieves good mud scraping effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation of the present invention will be described in detail below in conjunction with preferred embodiments.

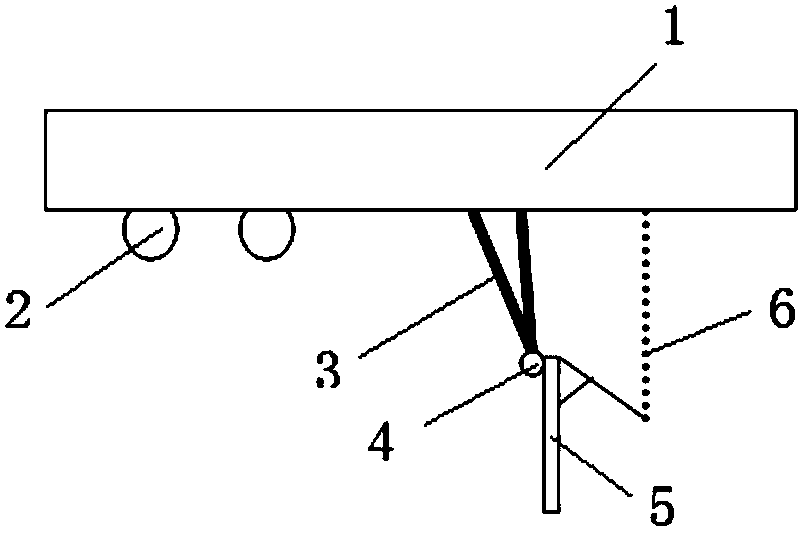

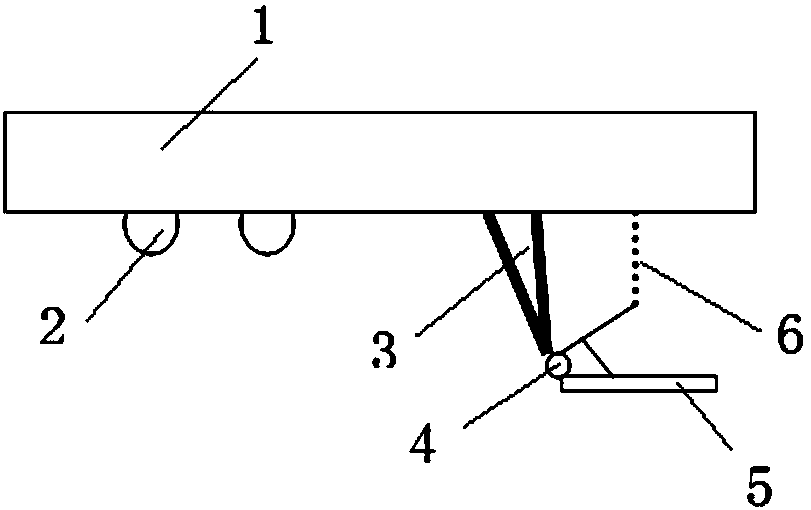

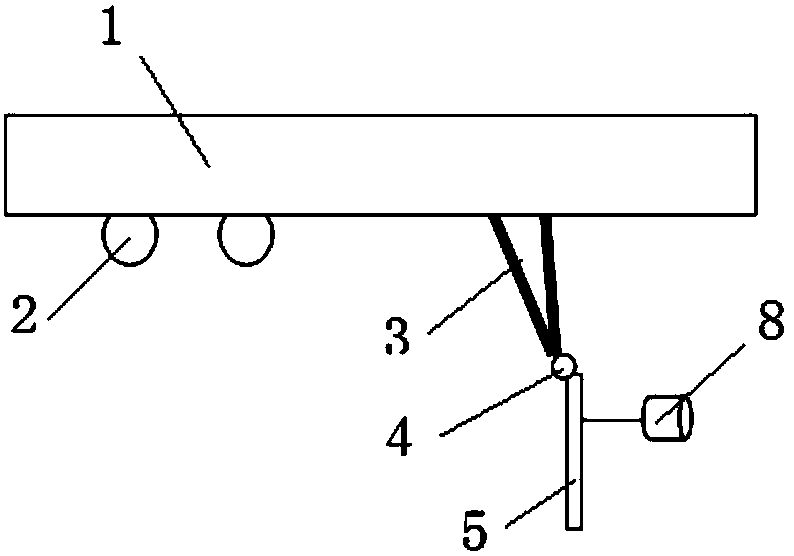

[0013] see attached figure 1 , 2 , this embodiment provides a slag discharge system for the upper layer of the air flotation tank, including a slag scraper 1 and a mud layer diversion weir plate 7, one side of the slag scraper is provided with a roller 2 that walks on the guide rail of the pool, The other side of the slag scraping vehicle is fixedly connected with a bracket 3, the top of the bracket is fixedly connected with a rotating shaft 4, and a slag scraping plate 5 is slidably connected to the rotating shaft. A steel wire 6 is fixedly connected to the surface of the slag scraping plate, and the other end of the steel wire The take-up pulley (not shown in the figure) keyed to the output shaft of the motor is connected.

[0014] see attached Figure 5 , the preferred solution of this embodiment is that the cross-section of the mud ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com