Overall hoisting device and method

A technology for integral hoisting and hoisting equipment, which is applied in the direction of transportation, packaging, and load hanging components, etc. It can solve the problems of affecting the locking effect of clips, the inability to continuously lift equipment, and affecting the quality of clips, etc., so as to achieve simple and convenient use and reduce Energy level requirements and the effect of reducing hoisting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0066] This embodiment is the overall hoisting of the propylene tower of the ethylene cracking unit of the CNOOC Hui Refining Phase II Project, using the overall hoisting device and method according to the present invention.

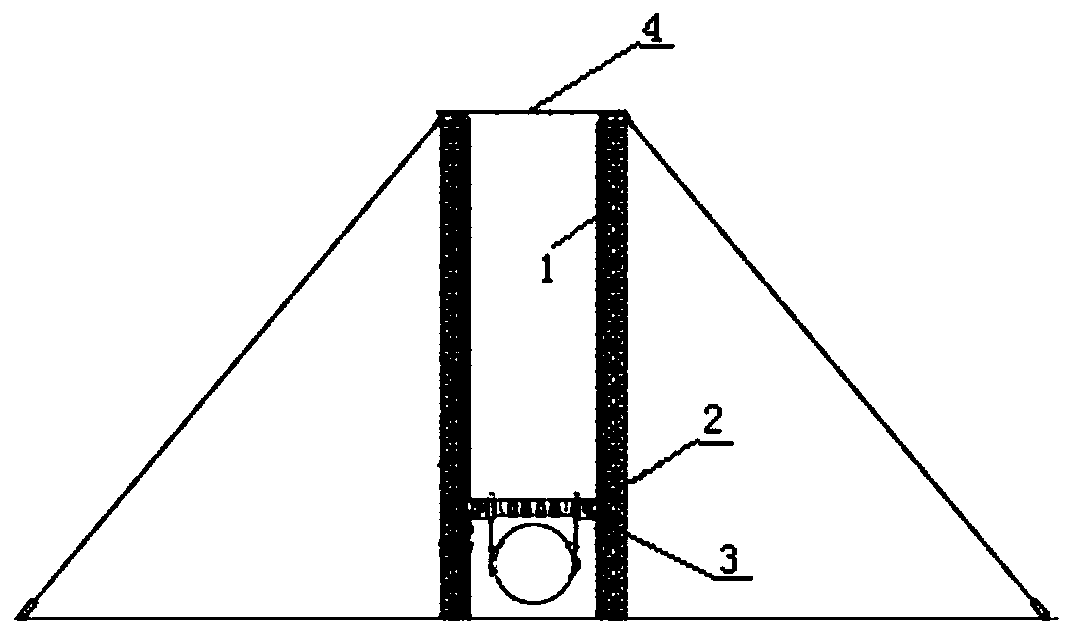

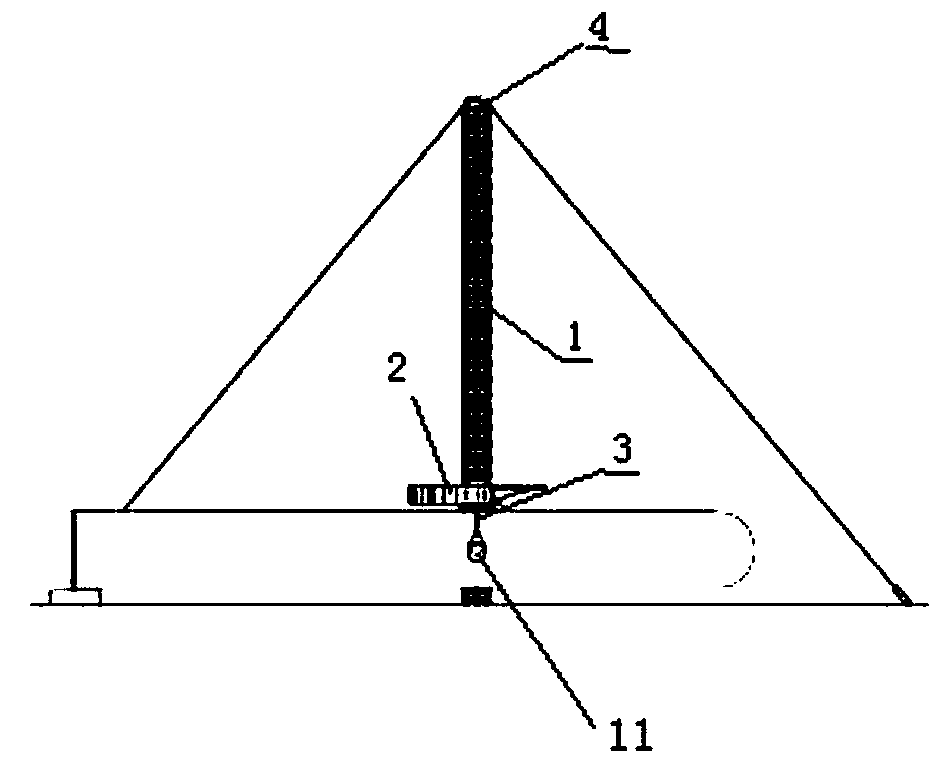

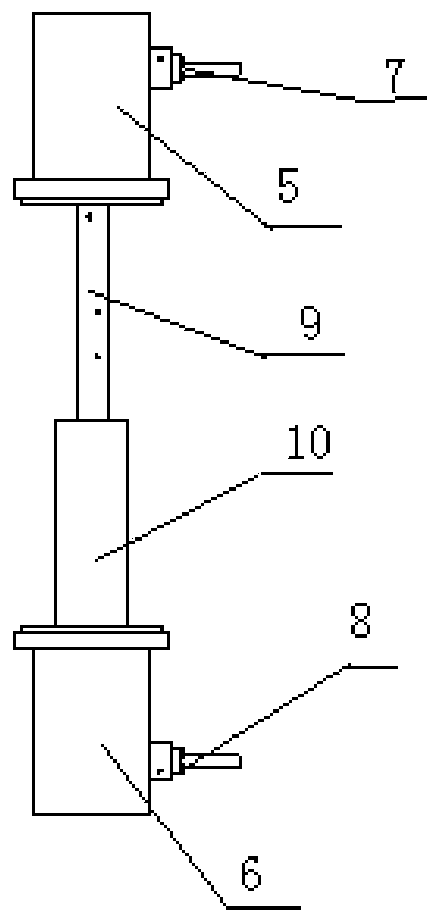

[0067] The specific content of the exemplary embodiment is described in detail below, figure 1 shows a front view of an integrated rigging arrangement according to an exemplary embodiment; figure 2 shows a side view of an integrated rigging arrangement according to an exemplary embodiment; image 3 A schematic diagram of a hydraulic jacking system according to an exemplary embodiment is shown.

[0068] according to figure 1 and 2 As shown, the overall lifting device according to the exemplary embodiment includes:

[0069] The two towers 1 are provided with vertical rails along the towers, and the rails are provided with pin holes. The two towers 1 are separated from each other and their heights are all lower than the height of the propylene tower, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com