Hoisting method of loop reactor

The technology of a loop reactor and hoisting method is applied in the direction of transportation, packaging, and load hanging components, etc., which can solve problems such as unfavorable equipment installation in place, easy deformation of the loop reactor, and hoisting quality accidents, so as to reduce hoisting Quality accidents, beneficial to installation in place, and the effect of reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

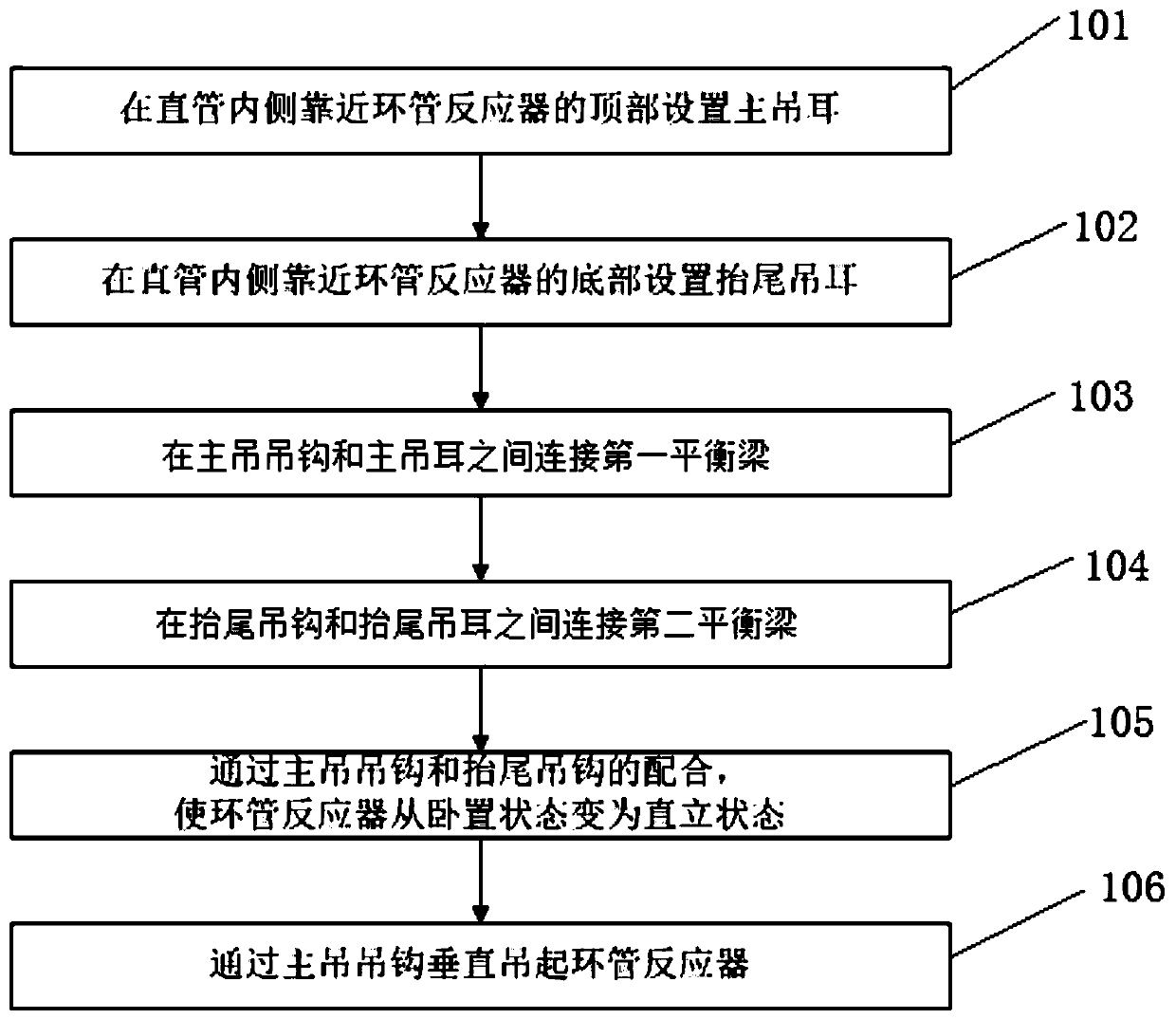

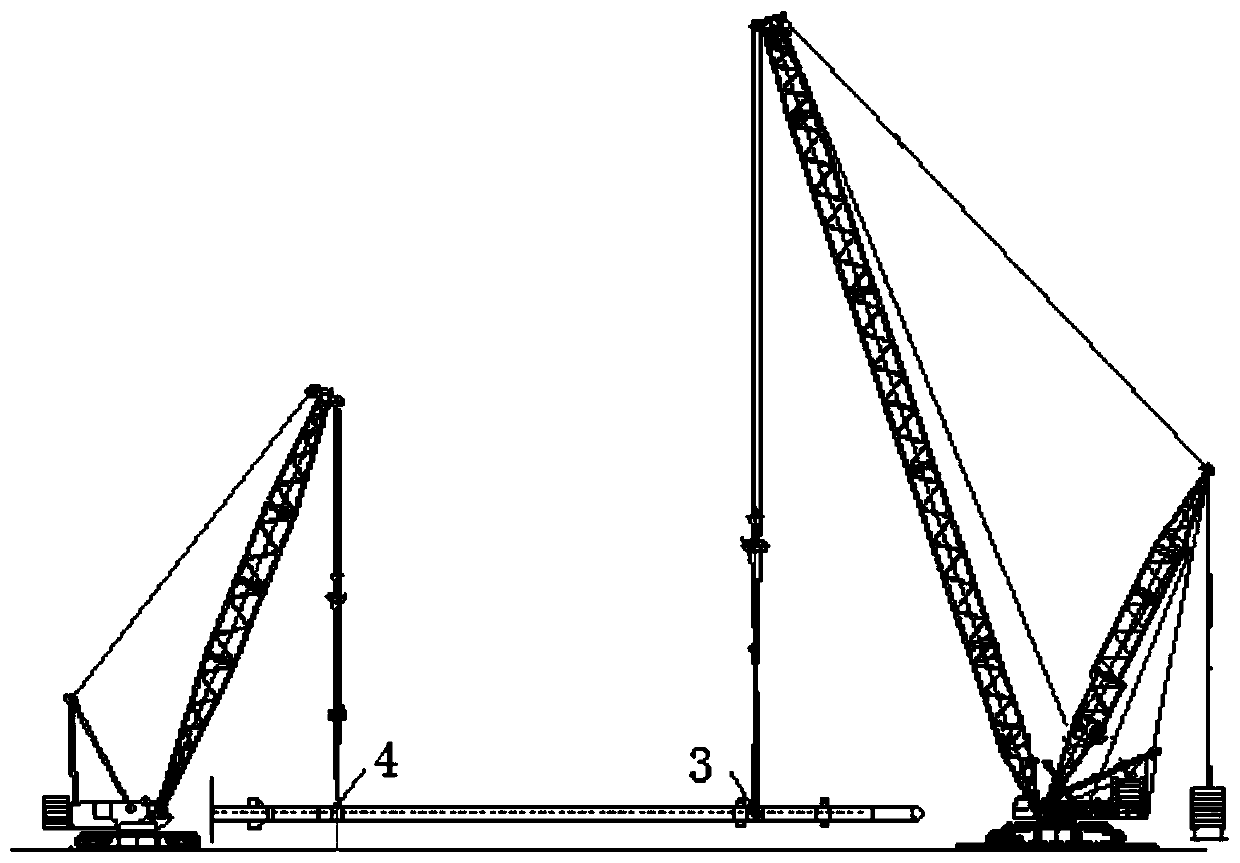

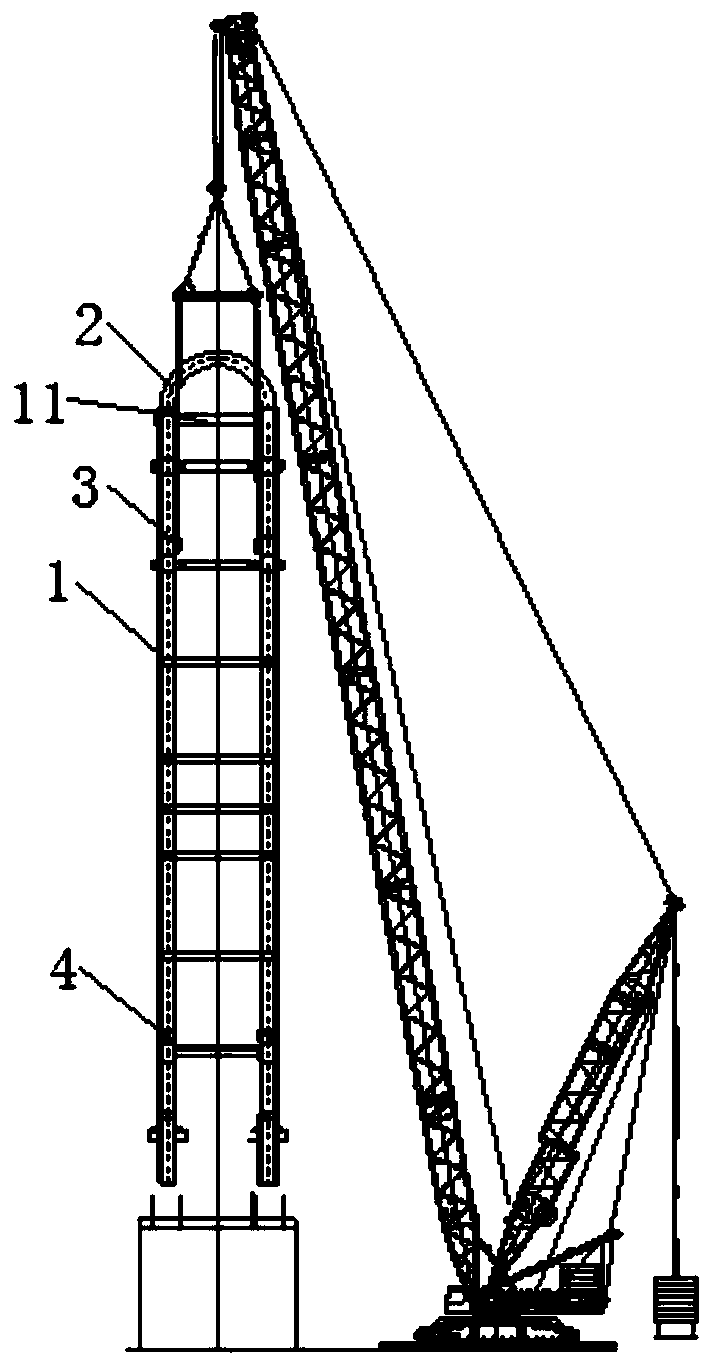

[0071] image 3 A schematic diagram showing the basic structure of a loop reactor according to one embodiment of the present invention, Figure 4 A schematic diagram showing the center of gravity and hoisting position of the loop reactor according to an embodiment of the present invention.

[0072] Such as image 3 and Figure 4 As shown, the loop reactor includes two straight pipes 1, a 180° elbow 2 and a connecting beam 11 connecting the two straight pipes. In the embodiment, the distance between the centers of the two straight pipes 1 of the loop reactor is 6.5m, the outer diameter of a single straight pipe 1 is 986mm, the wall thickness is 18mm, the length is 50m, and the weight is 59t; the weight of a single 180° elbow 2 is 7.5 t; connecting beam 11 weighs 7.5t.

[0073] In an embodiment, the hoisting method of the loop reactor comprises the following steps:

[0074] Step 201, according to the formula for calculating the combined center of gravity: L c =∑G i L i / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com