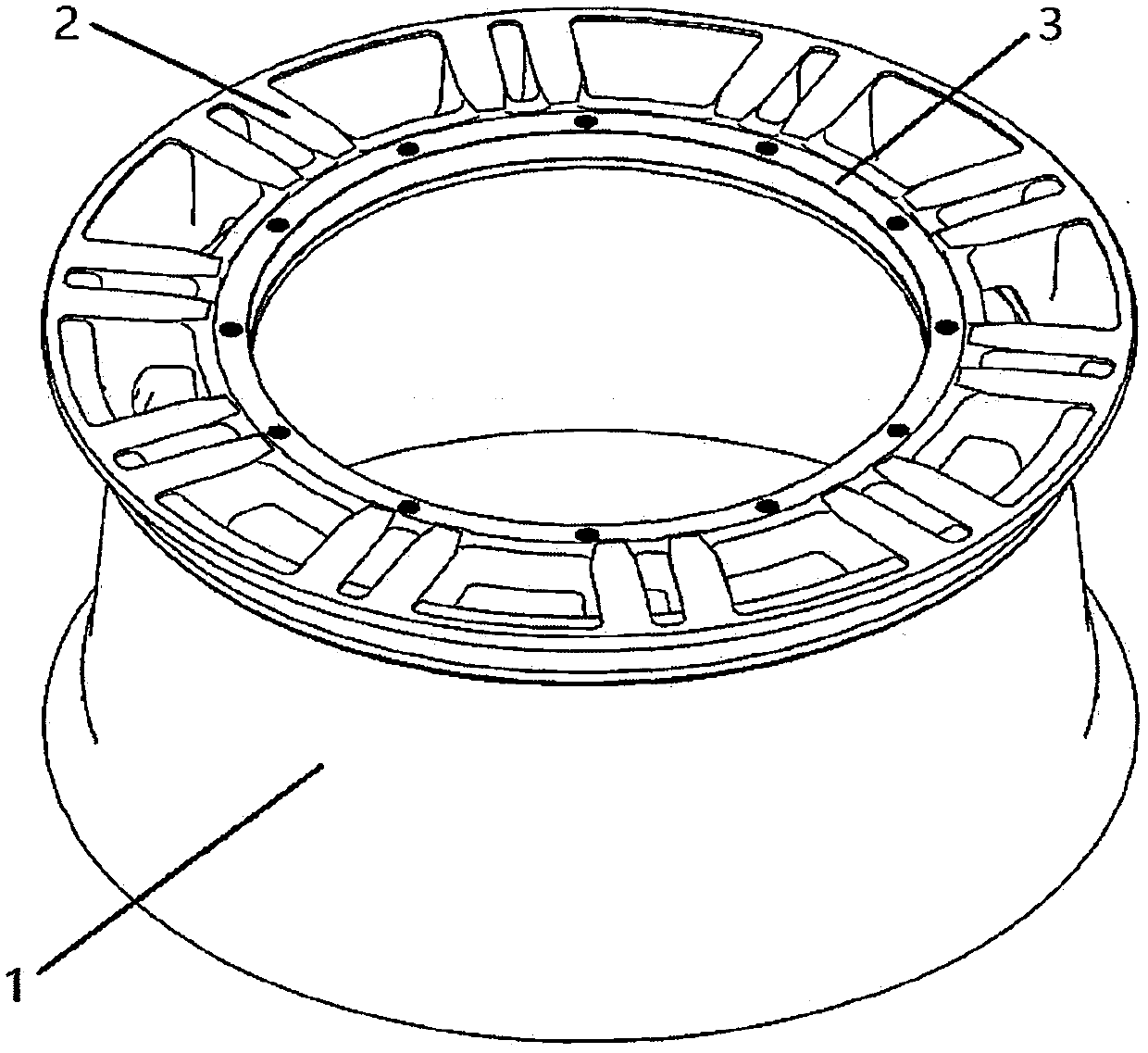

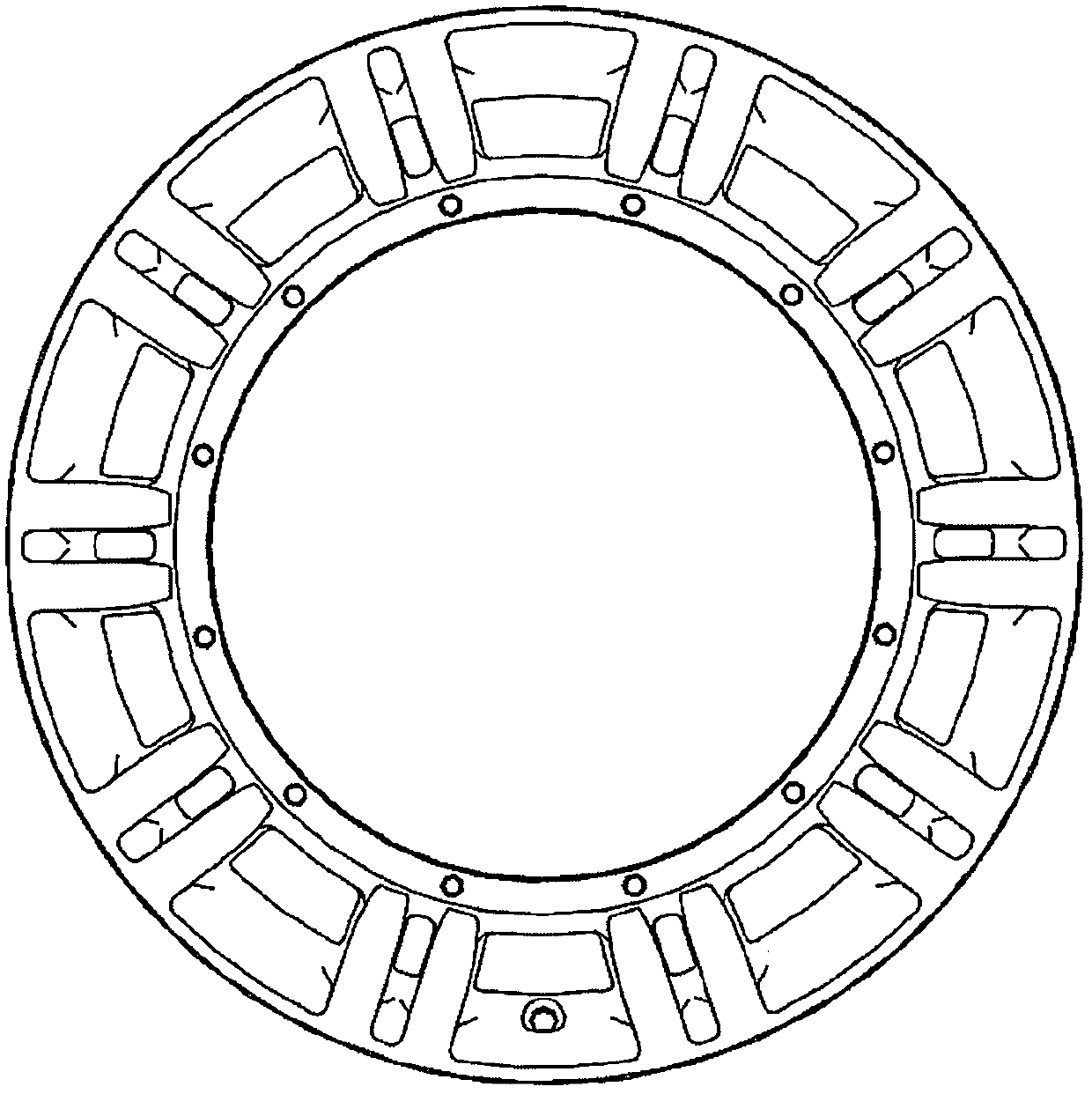

Integrated wheel type six-component sensor adaptive wheel rim

A six-component force sensor, integrated technology, applied in the direction of rims, instruments, measuring devices, etc., can solve the problems of high cost, can not be applied in actual production, etc., to achieve the effect of beautiful appearance, high size and shape and position accuracy, and flexible structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

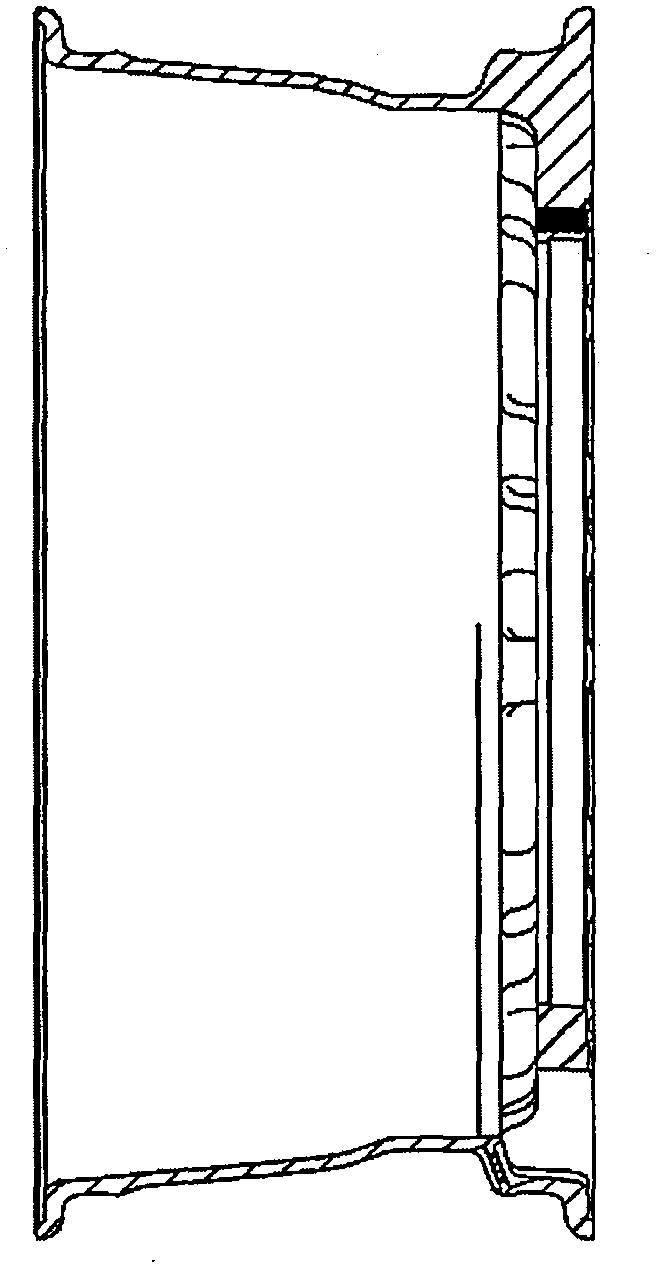

[0014] Option 1: Forging

[0015] Mold preparation: process the molds required for forging. Some of the molds can be borrowed from batch product molds, or modified based on batch product molds to reduce costs;

[0016] Substrate preheating: preheat the aluminum alloy substrate to reach the preset temperature;

[0017] Forging and pressing forming: forging and pressing the rim into semi-finished products through several times of forging and pressing through the forging die;

[0018] Heat treatment: heat treatment such as high-temperature solid solution, quenching, and low-temperature aging are performed on the semi-finished product to improve its mechanical properties;

[0019] Machining: Partially process heat-treated semi-finished products to achieve the structure and precision required by the drawings;

[0020] Surface treatment: paint the product.

[0021] Option 2: Spinning Forming

[0022] Mold preparation: process the spinning profile of the rim section, or directly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com