robot controller

A control device and robot technology, applied in program control, general control system, program control manipulator, etc., can solve problems such as decreased tracking accuracy and deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, embodiments of the robot system related to the present invention will be described in detail with reference to the drawings. It should be noted that in this manual, the ^ symbol marked above the English letter means "(English letter) hat ", the horizontal bar symbol added above the English letter means "(English letter) bar ", the dot mark marked above the English letter means "(English letter) dot ".

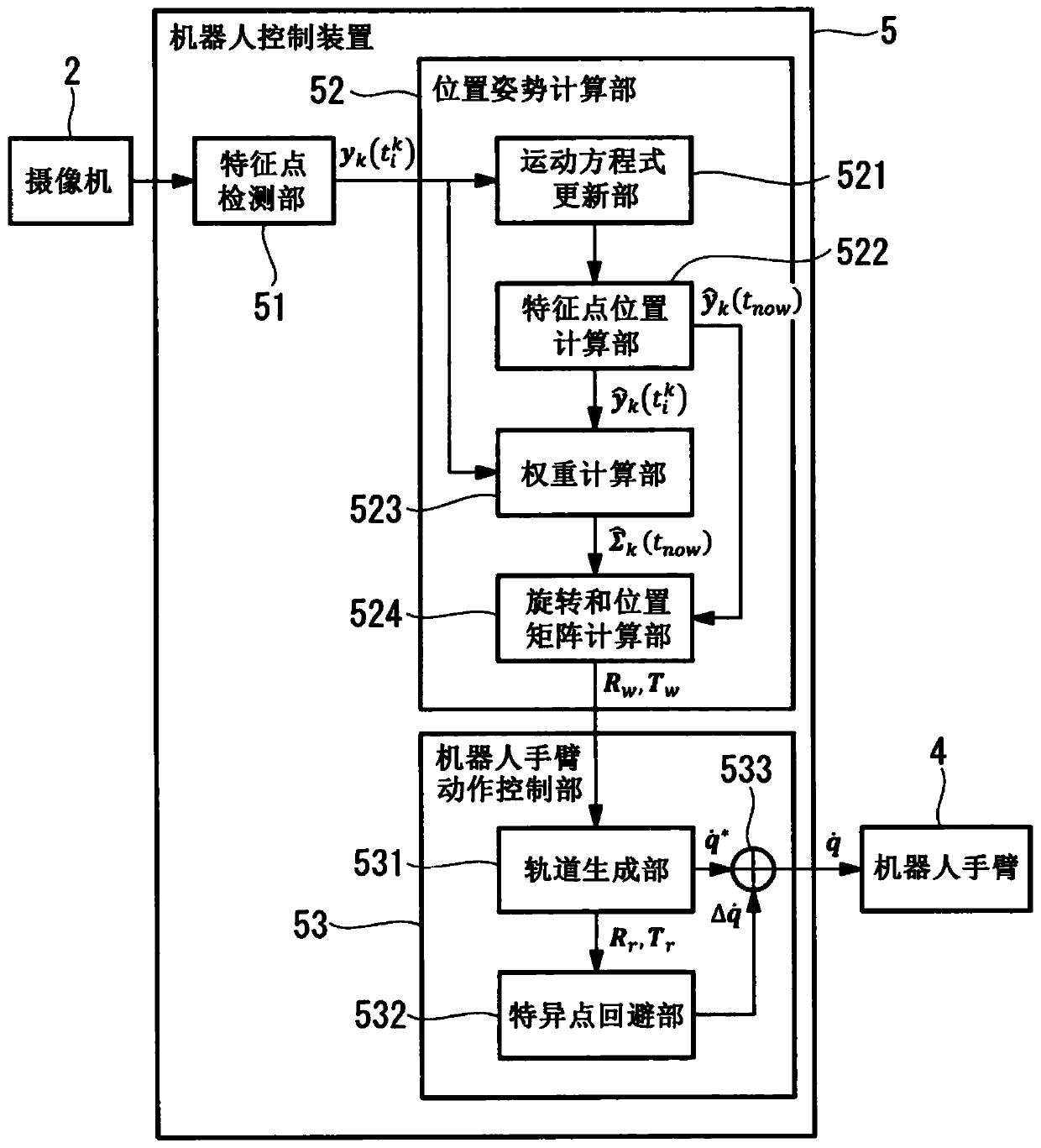

[0028] Such as figure 1 It is shown that the robot system 1 of this embodiment has a camera 2, a stand 3 for supporting the camera 2, a robot arm 4, and a robot control device 5 to which the camera 2 and the robot arm 4 are connected. The robot control device 5 is configured to perform visual servo control based on the visual information acquired from the camera 2 so that the robot arm 4 follows the movement of the workpiece (object) 7.

[0029] The workpiece 7 is placed on a conveying device 6 such as a conveyor belt or a rotating table, and the workpiece 7 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com