Tool suspension welding positioning device

A positioning device and tooling technology, applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve problems such as customer complaints and product deflation, and achieve the effect of reducing solder joint position deviation and simple and effective protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

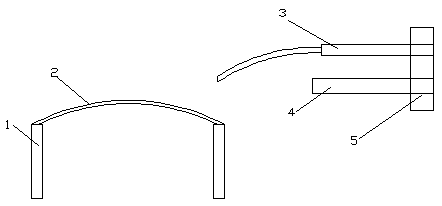

[0010] A frock suspension welding positioning device, the positioning device includes a frock 1, a welding guide device 2, a welding torch 3, and a limit steel block 4, the welding guide device 2 is arranged on the frock 1, and the device 1 has a Standardize the one-to-one corresponding marks of the solder joint positions to locate the Y-direction position of the solder joints. At the same time, the welding guide device 2 also plays a role in preventing the welding torch from hitting the part and causing the deformation of the part. The limit steel block 4 is arranged on the welding torch 3 The lower part is used to locate the position of the welding spot in the X direction. Through the effective combination of the welding guide device 2 and the limit steel block 4, the position of each welding spot at the rear sealing window of the rear bulkhead can be accurately located. At the same time, in order to avoid the phenomenon of welding conduction, a nylon block 5 is arranged betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com