Industrial material sorting machine

An industrial and machine technology, applied in the field of industrial material sorting machines, can solve the problems of lack of material sorting and impurity removal components, inconsistent production quality, poor operation continuity, etc., achieving obvious advantages in work efficiency, improving stability, and high cohesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

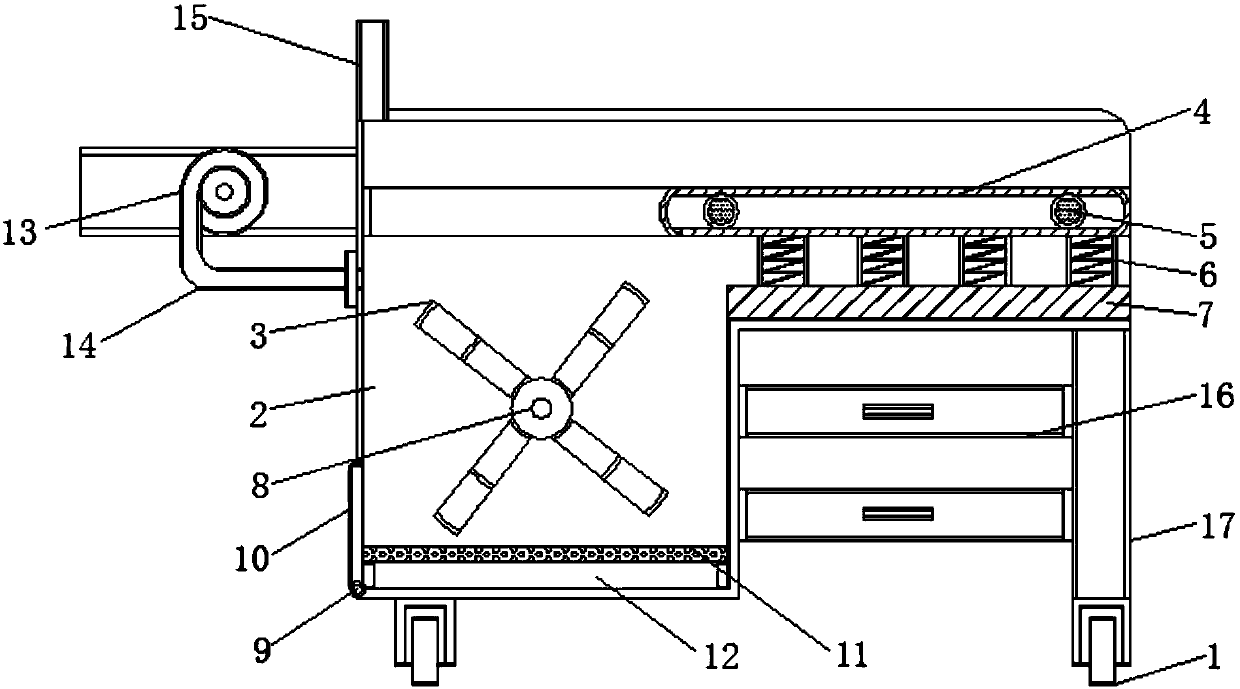

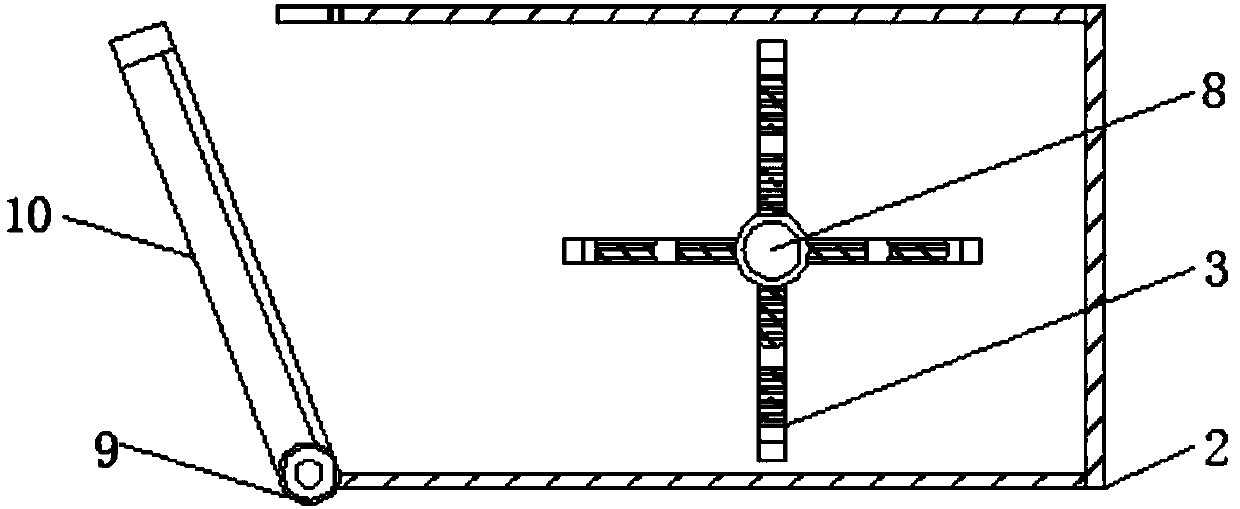

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0019] Such as Figure 1-2 As shown, an industrial material sorting machine includes a body 1, a sorting bin 2 and a sorting blade 3, the sorting bin 2 is located inside the body 1, and the sorting blade 3 is located inside the sorting bin 2, so One side of the body 1 is connected with an exhaust fan 13, one end of the exhaust fan 13 is connected with an air guide pipe 14, the air guide pipe 14 is connected with the sorting bin 2, and the lower end of the sorting blade 3 is provided with a filter screen 11, The lower end of the filter screen 11 is connected with a dust collection tank 12, and the surface of the body 1 is provided with a guide roller 5, and both sides of the guide roller 5 are rollingly connected with a conveying panel 4.

[0020]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com