Cyclodextrin nanocluster modified graphene membrane material and its preparation method for removing bisphenol A pollutants in water

A graphene membrane and nano-cluster technology, applied in water pollutants, water/sewage treatment, adsorbed water/sewage treatment, etc., can solve the problem of water treatment membrane materials, complicated separation, cumbersome separation, etc. Problems such as slow water purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

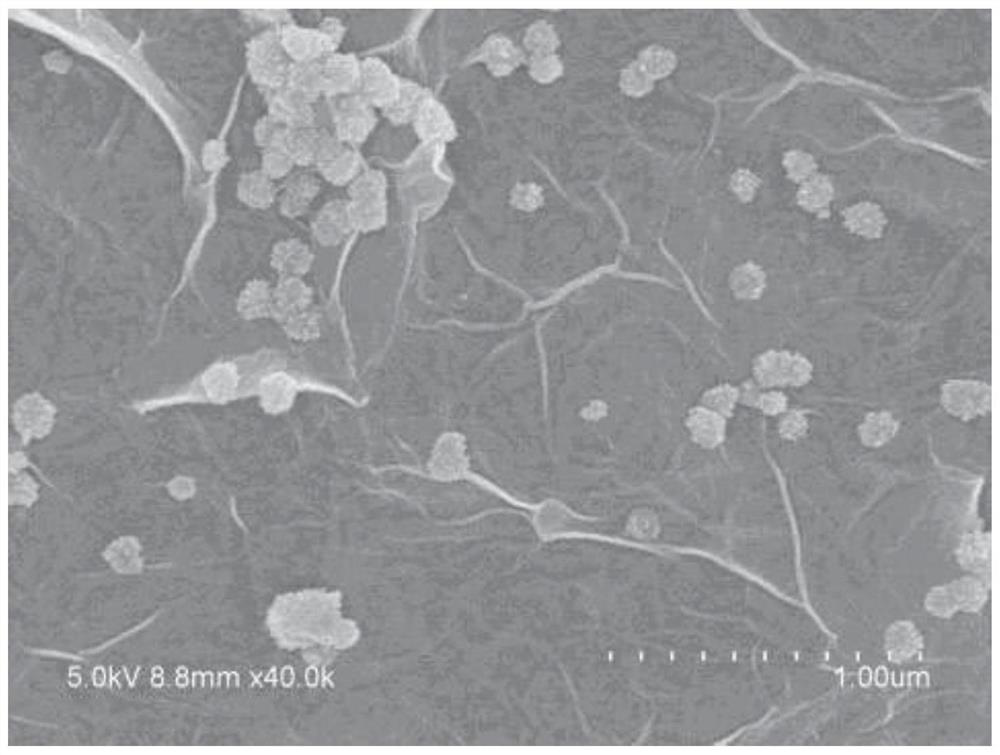

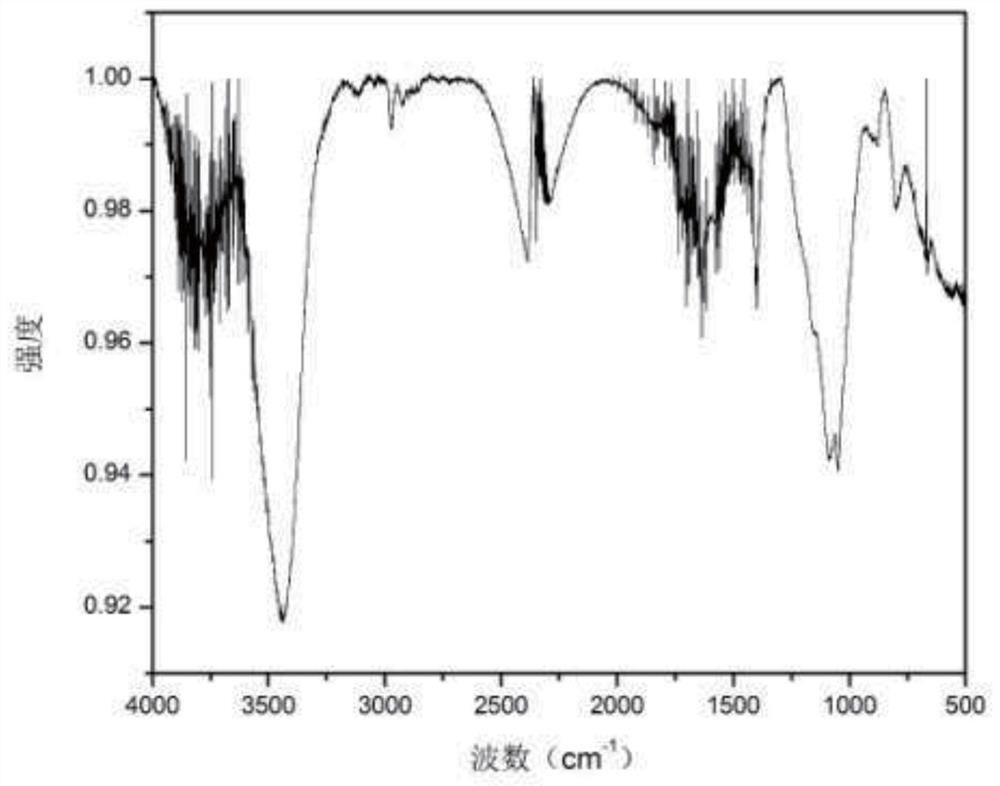

[0044] Embodiment 1. Preparation of a graphene membrane material modified by cyclodextrin nanoclusters.

[0045] Using the Staudenmaier method (see Poh HL, F, Ambrosi A, et al.Graphenes prepared by Staudenmaier, Hofmann and Hummers methods with consequent thermalexfoliation exhibit very different electrochemical properties[J].Nanoscale, 2012, 4(11): 3515-3522.) prepare graphene oxide dispersion liquid, Adjust the dispersion to a solid content of 0.5 mg / mL. Take 0.5g of monoamino-modified Y-cyclodextrin and mix it with 200mL of graphene oxide dispersion, and ultrasonically treat it for 0.5h to make it evenly mixed. The above mixture was heated to 100° C. for 16 h under stirring. Then, 10 mL of hydrazine hydrate was added to the reaction system, and the reaction was stirred at 100° C. for 24 h. The obtained mixture is filtered and washed several times, and the obtained solid is dispersed in water again, and filtered through a microporous filter membrane to form a cyclodextrin...

Embodiment 2

[0047] Embodiment 2. Preparation of a graphene membrane material modified by cyclodextrin nanoclusters.

[0048] Using Brodie's method (see Botas C, P, Blanco P, et al.Graphene materials with different structures prepared from the same graphite by the Hummers and Brodie methods [J].Carbon, 2013, 65: 156-164.) prepare the graphene oxide dispersion, adjust the dispersion to The solid content is 5.0 mg / mL. Take 2.0 g of monoamino-modified a-cyclodextrin and mix it with 200 mL of graphene oxide dispersion, and ultrasonicate for 0.5 h to make it evenly mixed. The above mixture was heated to 80°C for 8h under stirring. Then, 20 mL of hydrazine hydrate was added to the reaction system, and the reaction was stirred at 100° C. for 24 h. The obtained mixture is filtered and washed several times, and the obtained solid is dispersed in water again, and filtered through a microporous filter membrane to form a cyclodextrin-modified graphene membrane material on the filter membrane.

[...

Embodiment 3

[0050] Embodiment 3. Preparation of a graphene membrane material modified by cyclodextrin nanoclusters.

[0051] With the improved Hummers method (see Hummers WS, Offeman RE. Preparation of graphitic oxide. J Am Chem Soc 1958; 80: 1339; and. Zhou H, Yao W, Li G, Wang J, Lu Y. 4-ethylenedioxythiophene) hydrogel with excellent mechanical performance and high conductivity. Carbon 2013; 59: 495-502.) prepared a graphene oxide dispersion, and adjusted the dispersion to a solid content of 2.5 mg / mL. Take 1.0 g of monoamino-modified β-cyclodextrin and mix it with 200 mL of graphene oxide dispersion, and ultrasonicate for 0.5 h to make it evenly mixed. The above mixture was heated to 100° C. for 24 h under stirring. Then, 20 mL of hydrazine hydrate was added to the reaction system, and the reaction was stirred at 100° C. for 24 h. The obtained mixture is filtered and washed several times, and the obtained solid is dispersed in water again, and filtered through a microporous filter m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com