Link for a wheel suspension

A technology of wheel suspension and support rod, which is applied in the direction of suspension, connecting rod, vehicle parts, etc., which can solve the problems of expensive forgings and castings, and achieve the effects of reducing weight, saving billets, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

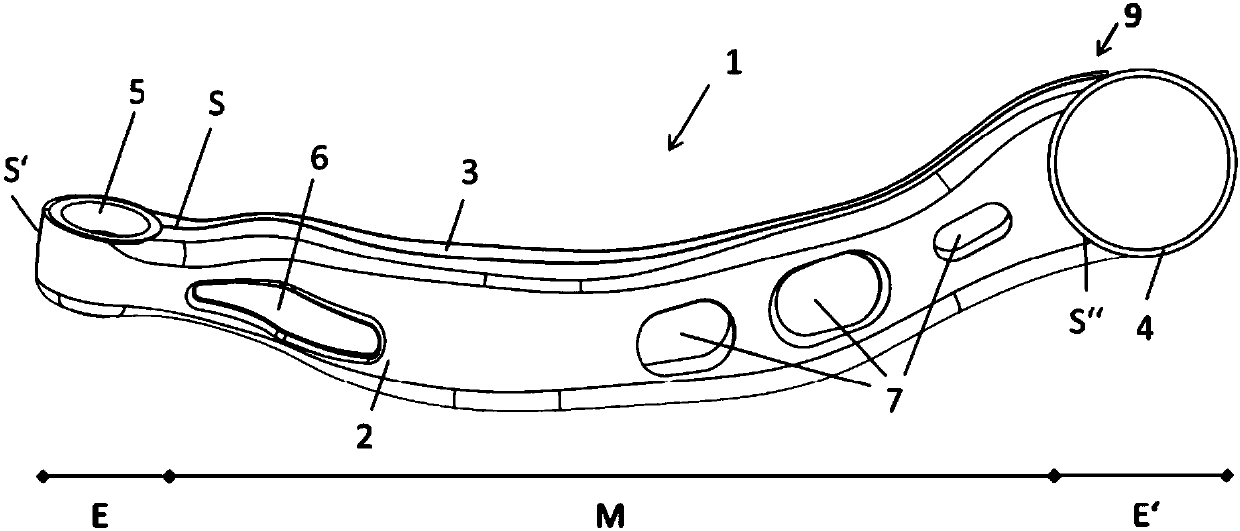

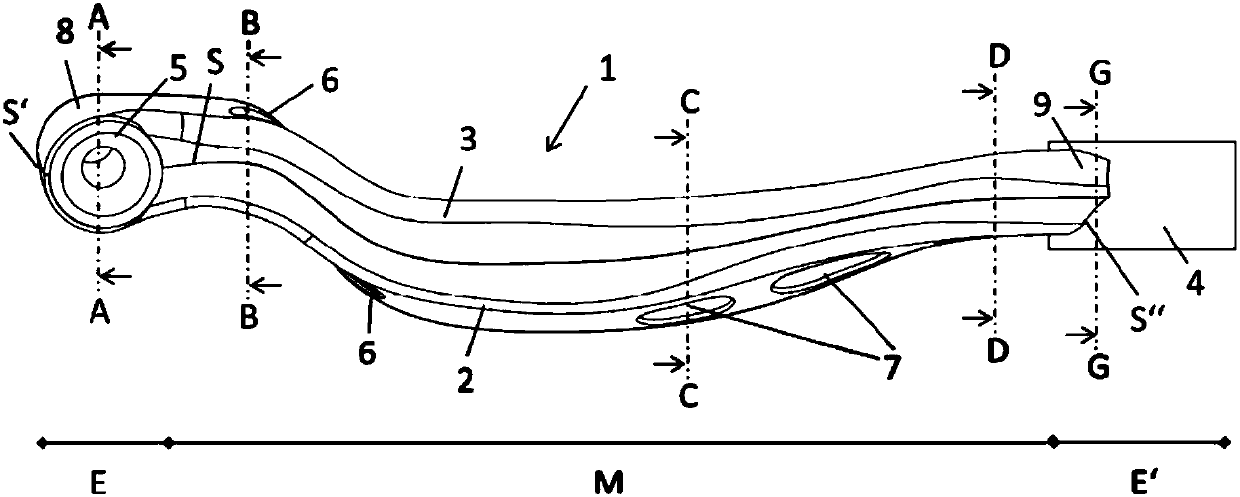

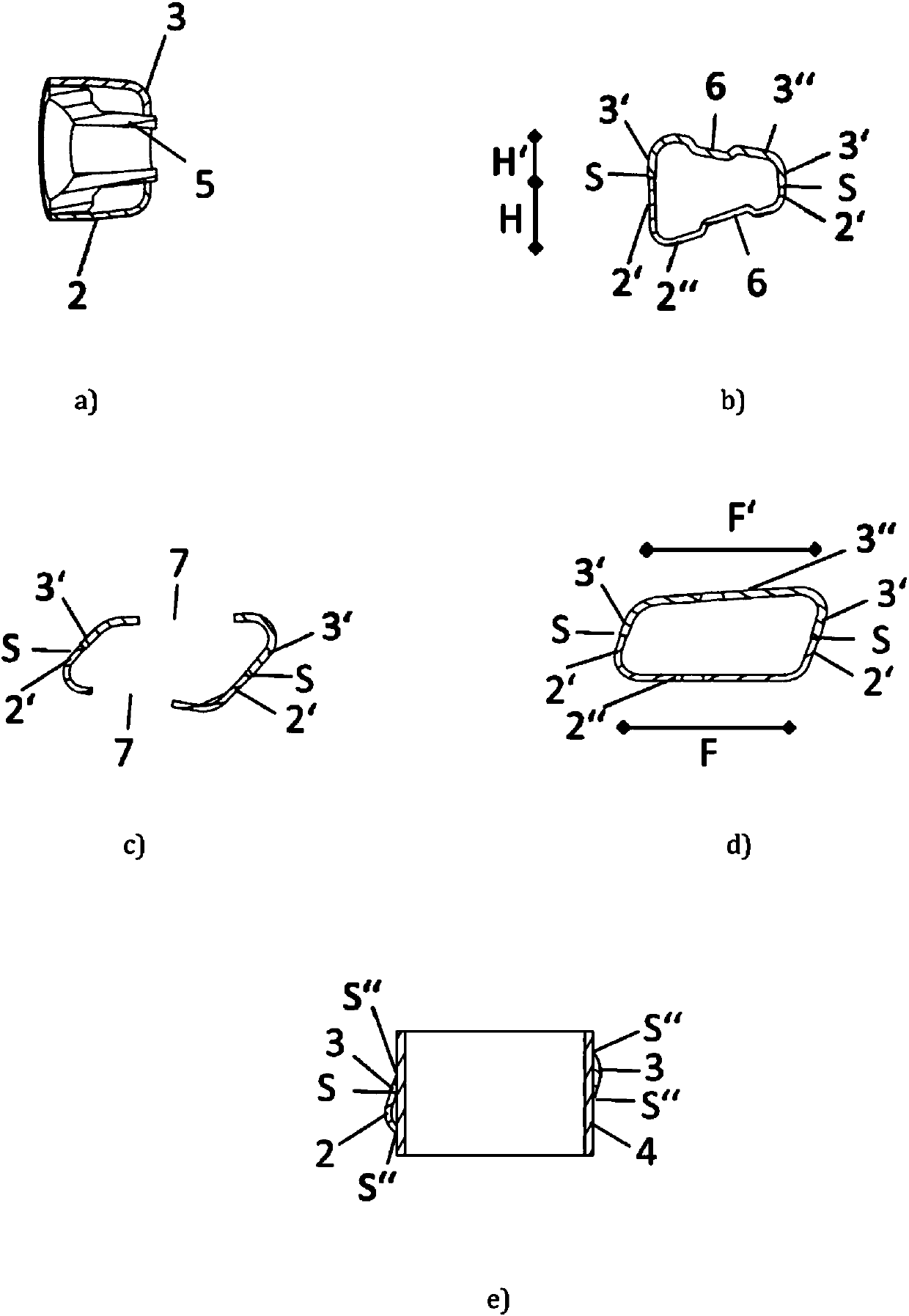

[0023] figure 1 and figure 2 Shown is an exemplary embodiment of a strut ( 1 ) according to the invention as, for example, a tie or strut, which is designed, for example, in the chassis area of a motor vehicle, particularly preferably in the area of the front axle and / or, for example, in the rear axle in the area. The support rod (1) has at least one middle section (M) and at least two end sections (E, E'). The end sections (E, E') have connection locations for accommodating connectors and / or couplings. In particular the middle section (M) of the support rod (1) is formed by at least two shells (2, 3), which can be made of one or different materials and have the same or at least partially different thicknesses . The housing is preferably made of a lightweight steel, for example a high-manganese steel with the same thickness or at least locally different thicknesses between 0.3 mm and 4.5 mm, so that high-strength, low-cost steel can be produced, for example by deep dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com