Coal seam mining-induced fissure field gas pressure determination system

A gas pressure measurement system technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the lack of modeling, simple gas pressure measurement, and it is difficult to intuitively observe the gas pressure in the coal seam mining fracture field Specific situations and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0066] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

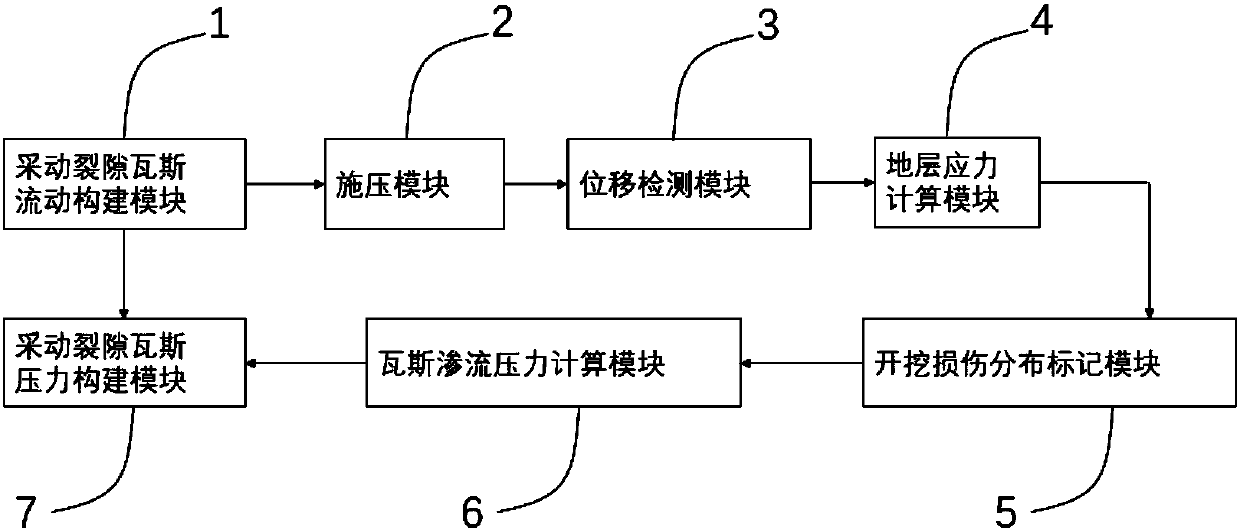

[0067] Such as figure 1 As shown, the coal seam mining fracture field gas pressure measurement system includes: mining fracture gas flow construction module 1, pressure application module 2, displacement detection module 3, formation stress calculation module 4, excavation damage distribution marking module 5, gas Seepage pressure calculation module 6, mining fracture gas pressure construction module 7.

[0068] Mining fracture gas flow construction module 1, mining fracture gas flow construction module 1 is connected with pressure application module 2, mining fracture gas pressure construction module 7, using infrared and ultrasoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com