Positive pressure sealing performance test device

A testing device and sealing technology, which are used in fluid tightness testing, measuring devices, and liquid tightness measurement using liquid/vacuum degree. Convenience and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

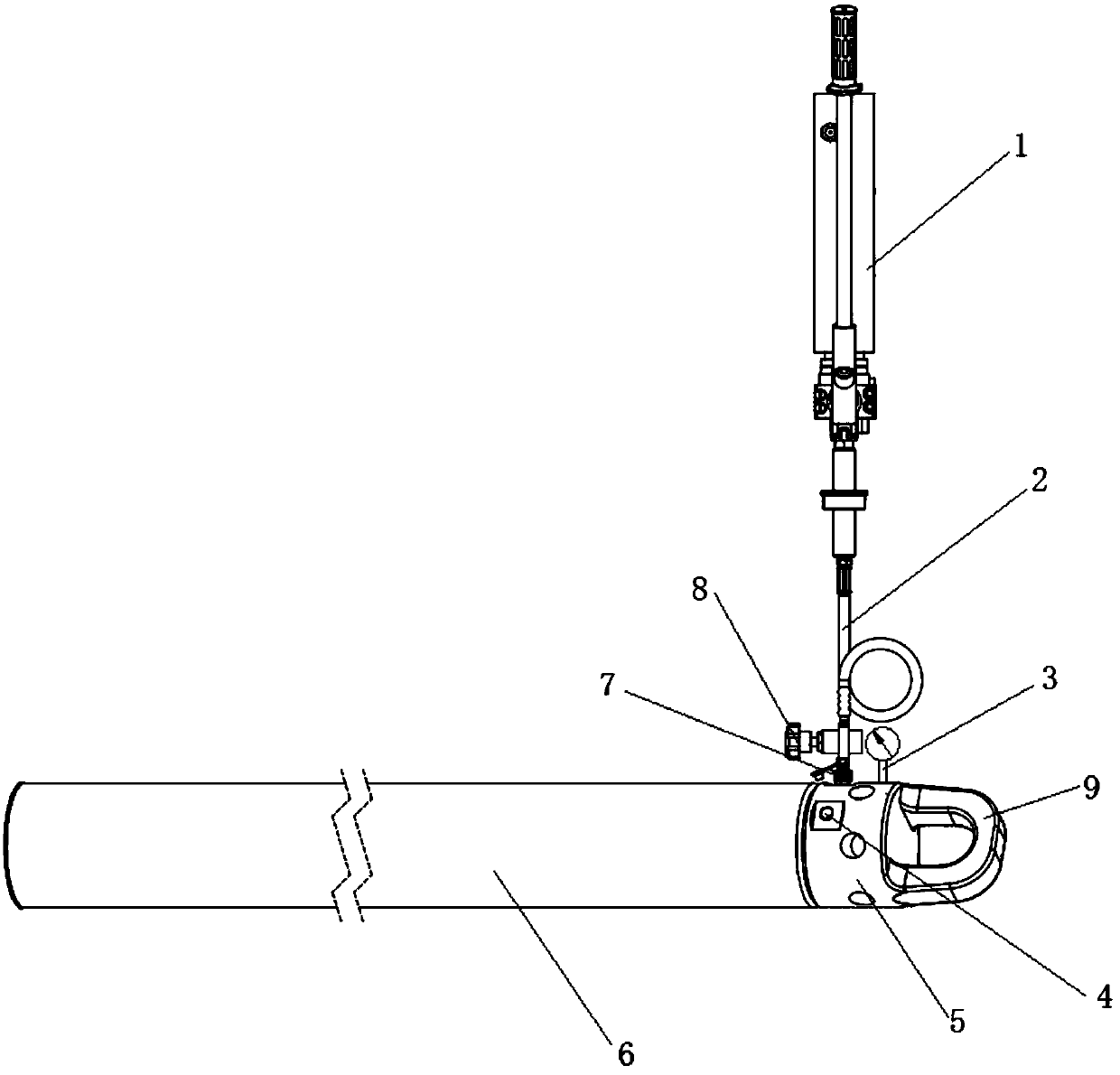

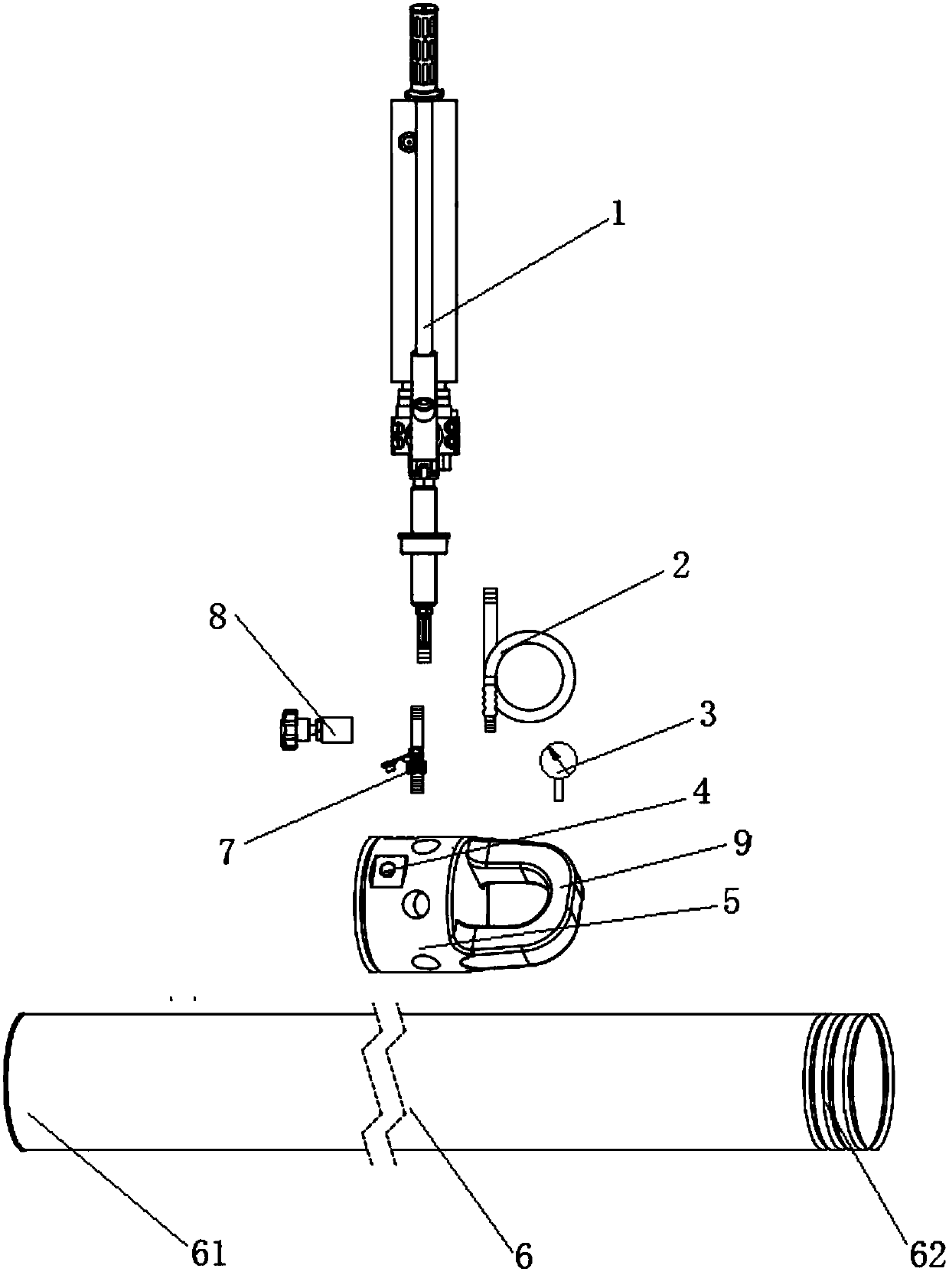

[0026] In order to solve the problem that in the prior art, only vacuum pumping can be used for airtightness testing, and the airtightness is tested under negative pressure. The test pressure is only 1Mpa, which is difficult to meet the airtightness requirements under high pressure. The invention provides a positive pressure tightness test device, specifically, refer to figure 1 and figure 2 , the device includes a sleeve 6, a sealing joint 5, a pressing device 1 and a quick joint 7, the sleeve 6 includes a sealing end 61 and an opening end 62, and the sealing joint 5 and the opening end 62 of the sleeve 6 Threaded connection, the pressing device 1 is set on the sealing joint 5 through the quick joint 7, the quick joint 7 is provided with a pressure valve 8, and the sealing joint 5 is provided with a pressure gauge 3.

[0027] Further, the pressing device 1 is provided with a handle, which is convenient for manual pressing.

[0028] Specifically, the sealing end 61 of the s...

Embodiment 2

[0039] This embodiment has provided another group of sealing instructions that utilize this sealing test device to test, such as figure 1 and figure 2 As shown, it includes a sleeve 6, a sealing joint 5, a pressing device 1 and a quick joint 7. The sleeve 6 includes a sealing end 61 and an opening end 62, and the sealing joint 5 is threaded with the opening end 62 of the sleeve 6. The pressing device 1 is set on the sealing joint 5 through the quick joint 7, the quick joint 7 is provided with a pressure valve 8, and the sealing joint 5 is provided with a pressure gauge 3.

[0040] Further, the pressing device 1 is provided with a handle, which is convenient for manual pressing.

[0041] Specifically, the sealing end 61 of the sleeve 6 is integrally formed with the sleeve 6 and then sealed, and the opening end 62 of the sleeve 6 is provided with an external thread, and the opening end 62 of the sleeve 6 is fitted together. The inner side of the sealing joint 5 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com