Spatial optical axis offset system for refrigeration type infrared thermal imaging lens

A technology of infrared thermal imaging and spatial light, which is applied in the field of spatial optical axis offset system, can solve the problems of large space occupation, complicated optical adjustment, and unfavorable secondary adjustment of optical axis, etc., and achieves convenient secondary operation and simplified adjustment. Calibration process, the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

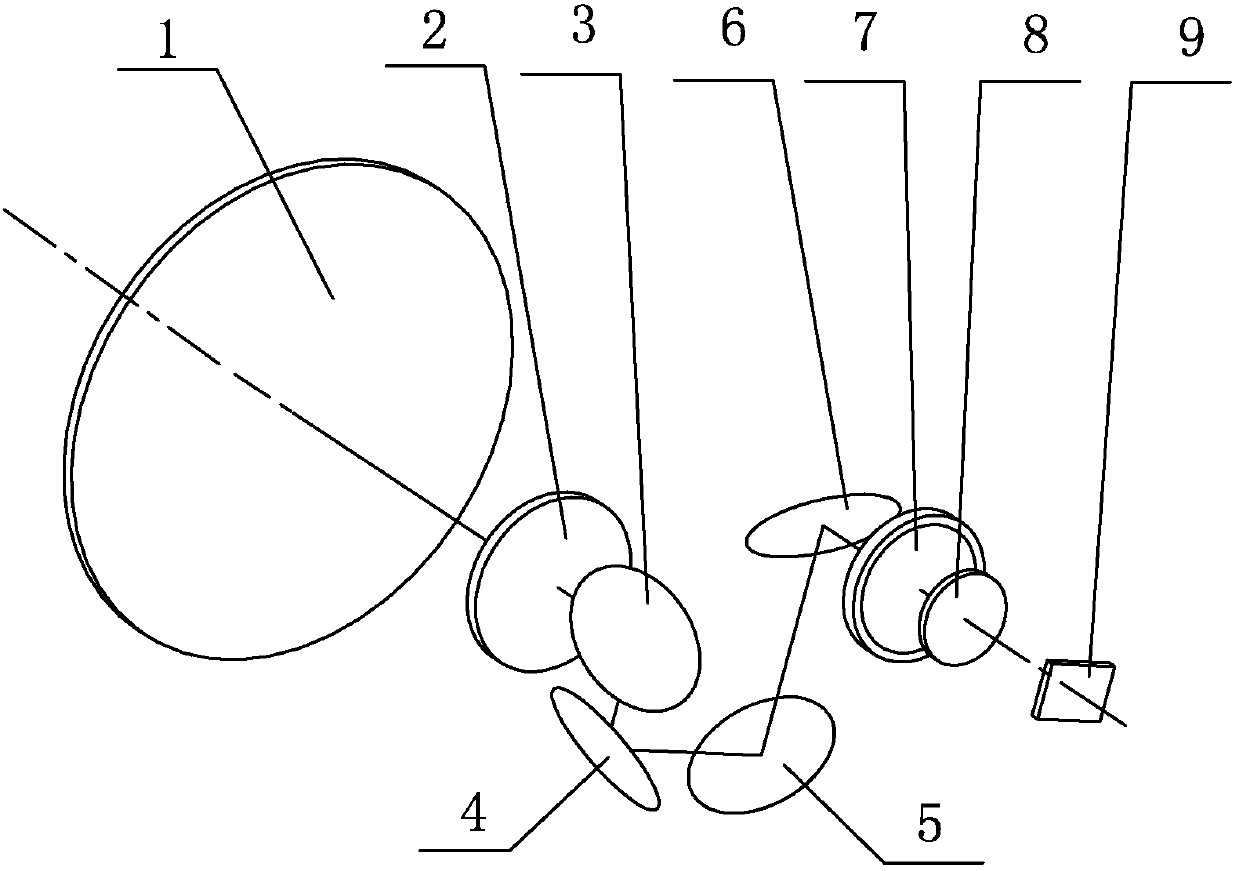

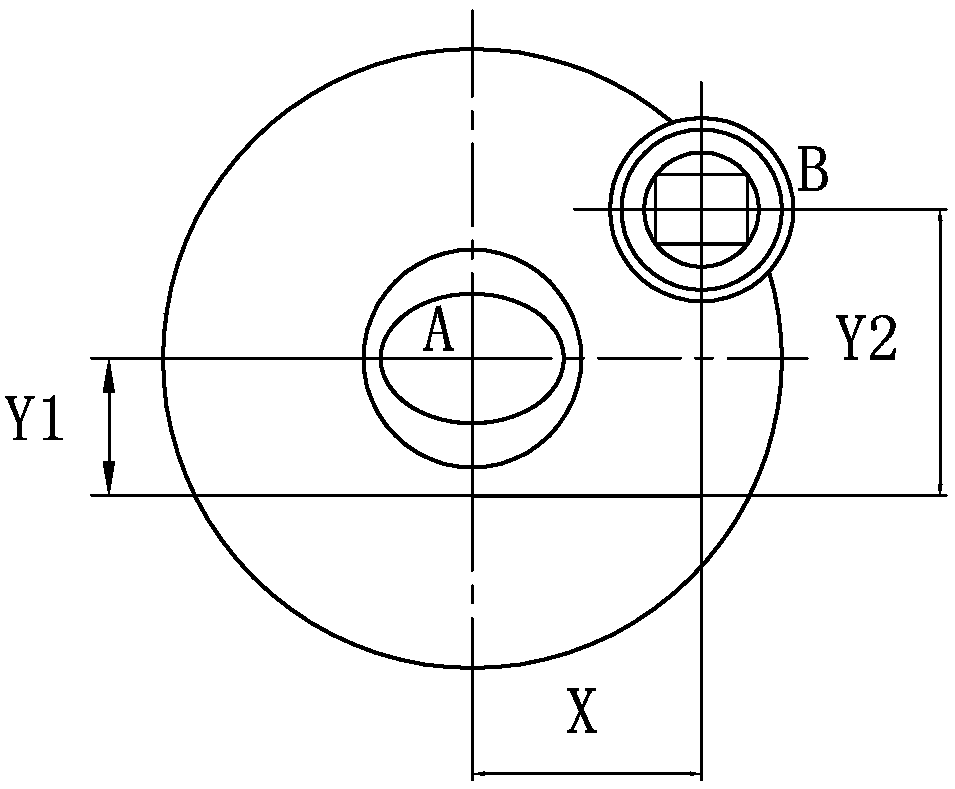

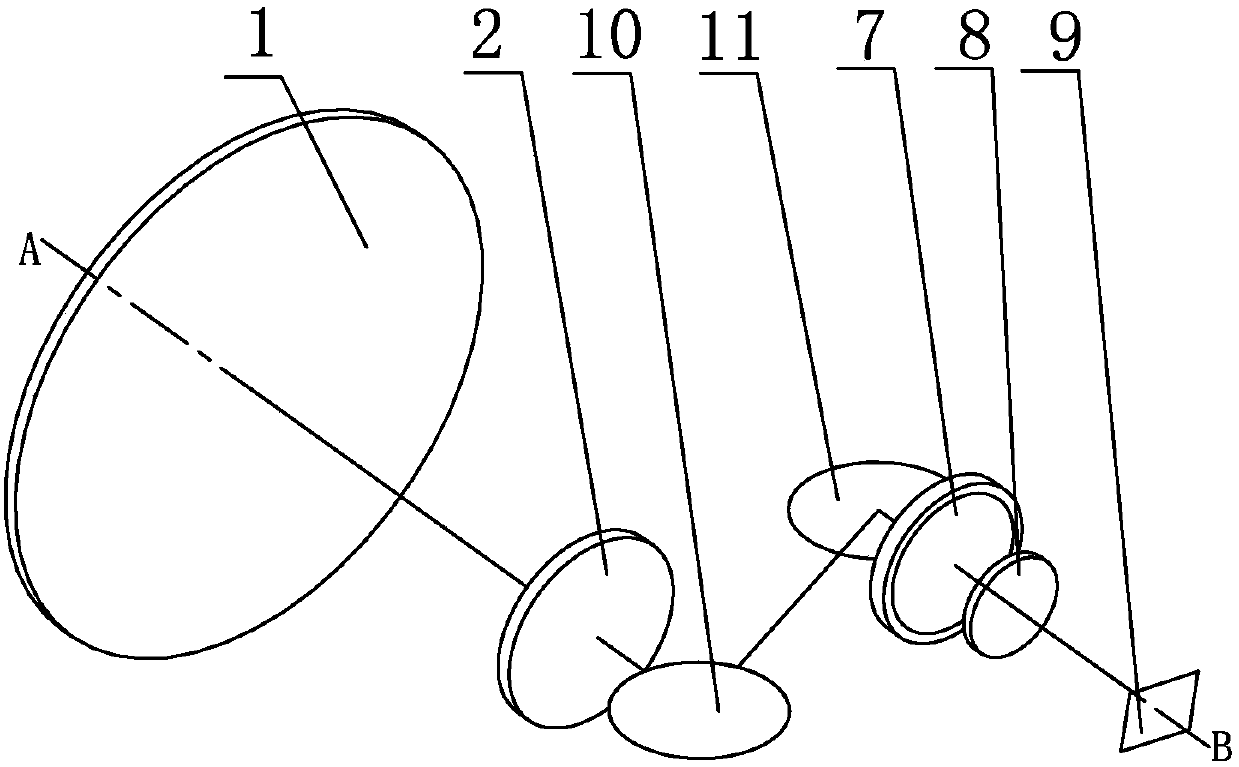

[0021] Such as image 3 , Figure 4 As shown, the present invention includes a front mirror group 1, a relay image transfer front group 2, a first reflector 10, a second reflector 11, a relay image transfer rear group 7, a detector protection window 8, and a detector sensing surface 9 And the inclined pad 12; the front mirror group 1, the relay image transfer front group 2, the first reflector 10, the second reflector 11, the relay transfer image rear group 7, the detector protection window 8, the detector induction The surface 9 is arranged in the lens barrel, and the inclined pad 12 is arranged outside the lens barrel;

[0022] The front mirror group 1 and the relay relay front group 2 are parallel to each other and the optical axes coincide; the relay relay rear group 7, the detector protection window 8 and the detector sensing surface 9 are parallel to each other and the optical axes coincide;

[0023] It is stipulated that the optical axis of the front mirror group 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com