Rolling friction pair used for friction-wear test and test method thereof

A friction and wear test, rolling friction technology, applied in the direction of using mechanical devices, measuring devices, instruments, etc., can solve the problems of inability to simulate rolling friction pairs, hinder the research of rolling friction pairs, etc., and achieve the embedding method is simple, easy to operate, and high reliability. , The effect of the simple structure of the parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below.

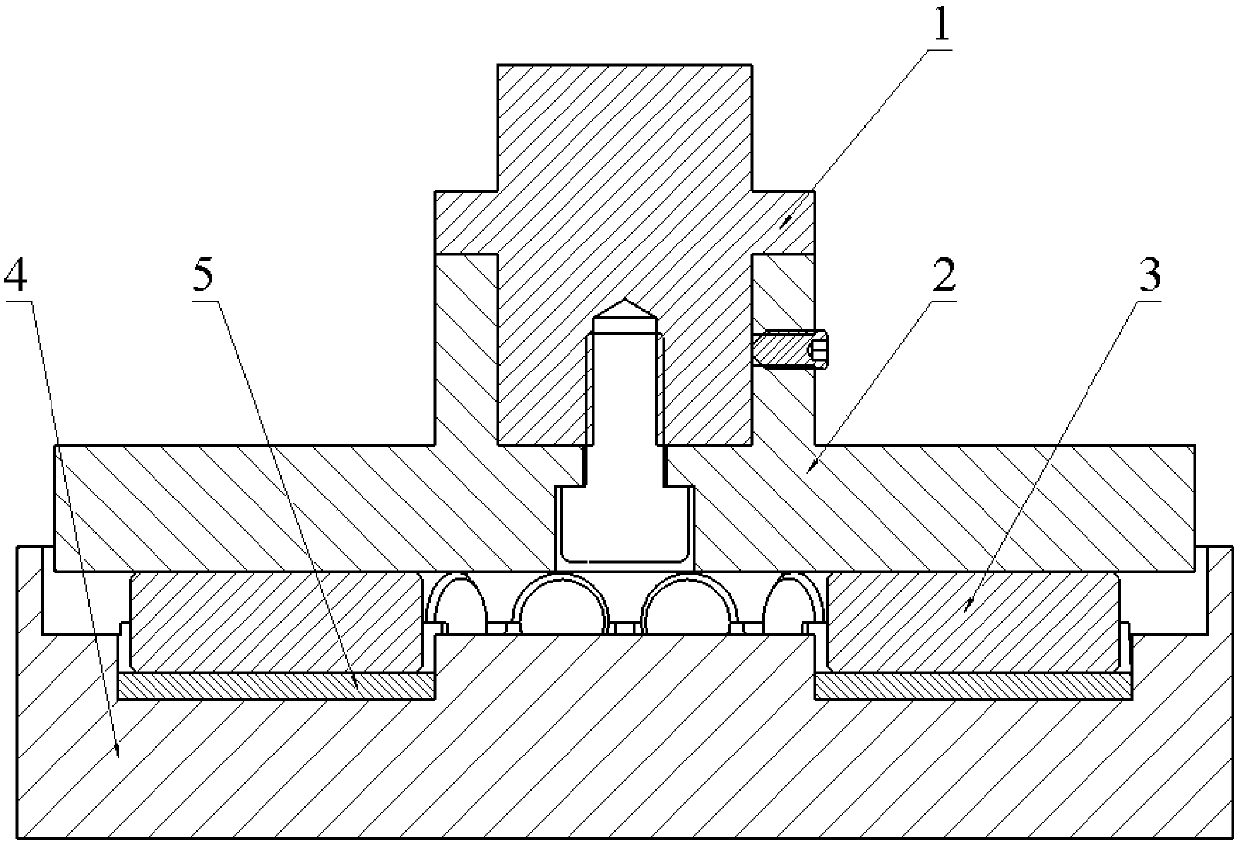

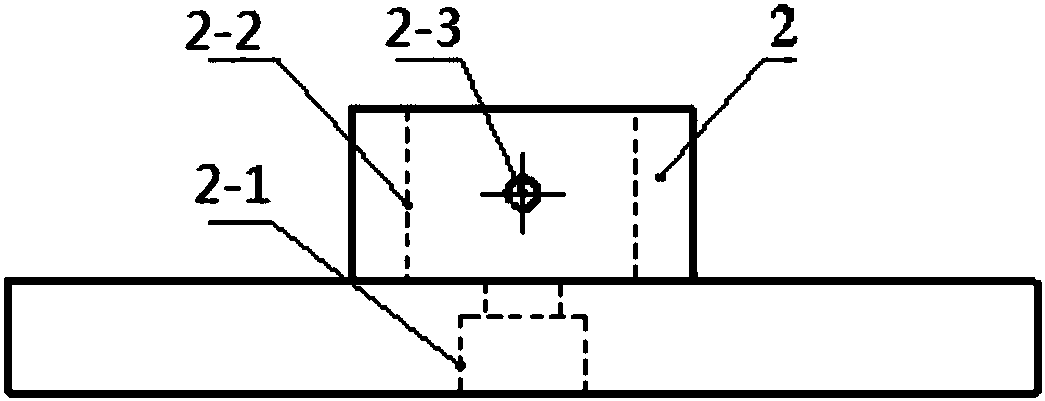

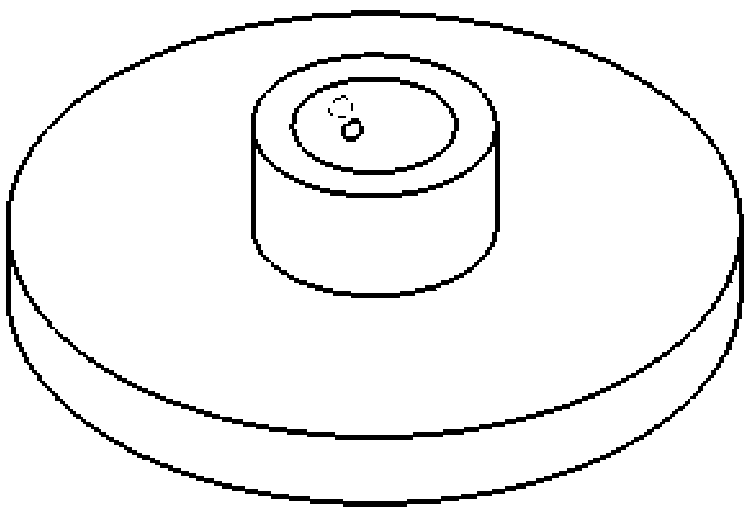

[0029] A rolling friction pair used for friction and wear tests, comprising: a bearing shaft 1, an upper pressing plate 2, a roller 3, a fastening chuck 4, and a roller disk 5. Wherein, the upper end of the bearing shaft 1 is fixedly connected with the load applying part of the friction and wear testing machine, the bearing shaft 1 is in clearance fit with the blind hole 2-2 of the upper platen 2, and the two are fixed together by the screw through the screw hole 2-1 At the same time, the fastening screw passes through the screw hole 2-3 to ensure that the two do not rotate relative to each other, and the load applied by the friction and wear testing machine can be transmitted to the upper platen 2 through the bearing shaft 1. The screw completely fixes the fastening chuck 4 and the rotating spindle chassis of the friction testing machine through the screw hole 4-2, and the fastening chuck 4 can obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com