Hydraulic engineering desilting device

A dredging device and water conservancy engineering technology, which is applied in the direction of transportation and packaging, mechanically driven excavators/dredgers, ships, etc., can solve the problems of high labor intensity of dredging, increased maintenance costs, and inconvenience of sanitation workers, achieving improved The effect of dredging work efficiency, low production cost, and simplified dredging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

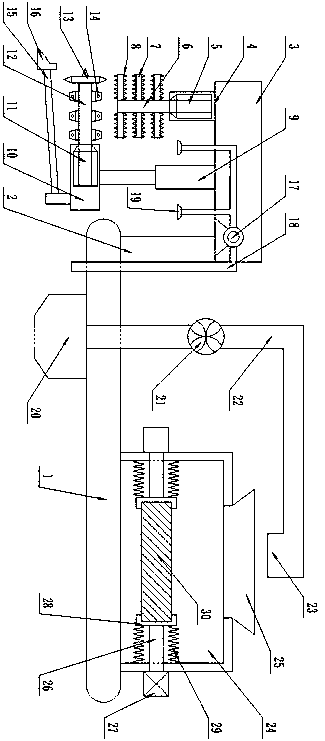

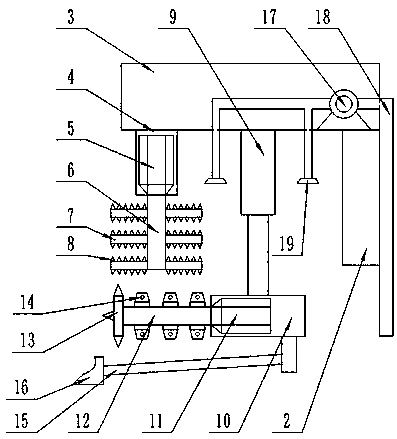

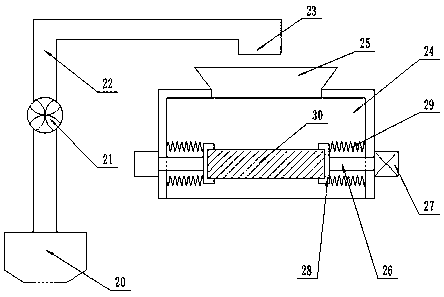

[0018] like Figure 1 to Figure 3 As shown, this specific embodiment adopts the following technical solutions: a dredging device for water conservancy projects, comprising a dredging hull 1, a column 2, a beam 3, a first waterproof casing 4, a first motor 5, a first rotating shaft 6, a stirring Rod 7, stirring tooth 8, lifting rod 9, second waterproof casing 10, second motor 11, second rotating shaft 12, breaking hammer 13, dredging plate 14, connecting rod 15, trowel 16, water pump 17, water pipe 18 and nozzle 19; a column 2 is fixedly connected to the left side of the upper surface of the dredging hull 1; a beam 3 is fixedly connected to the top of the column 2; A waterproof casing 4; a first motor 5 is fixedly connected in the cavity of the first waterproof casing 4; a first rotating shaft 6 is connected to the output shaft of the first electric motor 5, and the first rotating shaft 6 and the horizontal plane are perpendicular to each other; the outer surface of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com