Preparation method of glucolactone and tobacco essence prepared by applying glucolactone

A technology of gluconolactone and tobacco flavor, which is applied in the fields of spices and tobacco, can solve problems such as restrictions, and achieve the effects of softening smoke, improving cigarette quality, and simple ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, the preparation method of described a kind of gluconolactone is characterized in that concrete steps are as follows:

[0021] (1) Prepare glucose, water and 30% hydrogen peroxide solution according to the mass ratio of 4:5:1. First add all the glucose into a 250mL Erlenmeyer flask, then add water, and then add 30% hydrogen peroxide solution. The hydrogen solution constitutes the reaction solution, and the frosted stopper is tightly covered;

[0022] (2) Place the Erlenmeyer flask in an oven, set the temperature to 120°C, and the reaction time reaches 1.5 hours. After measuring the pH value of the solution is 2.47, the reaction is complete; and the reaction vessel is taken out from the oven, and cooled to room temperature naturally. The obtained transparent and clear solution is the reactant gluconolactone.

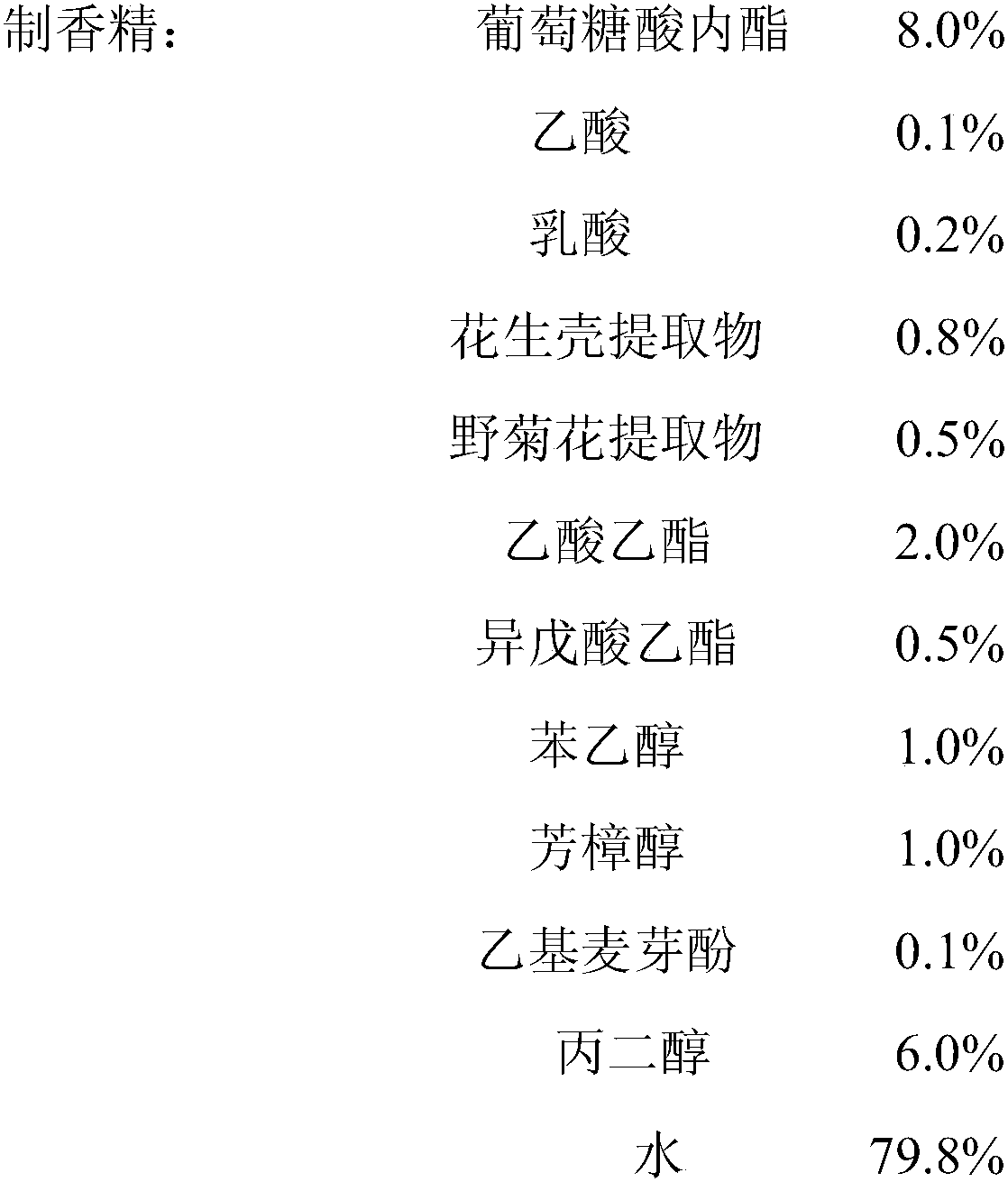

[0023] Adopt the gluconolactone prepared in embodiment 1 according to the following formula of mass percentage

[0024]

[0025] First, take half...

Embodiment 2

[0026] Embodiment 2, the preparation method of described a kind of gluconolactone is characterized in that concrete steps are as follows:

[0027] (1) Prepare glucose, water and 30% hydrogen peroxide solution according to the mass ratio of 5:4:1. First add all the glucose into a 250mL Erlenmeyer flask, then add water, and then add 30% hydrogen peroxide solution. The hydrogen solution constitutes the reaction solution, and the frosted stopper is tightly covered;

[0028] (2) Place the Erlenmeyer flask in an oven, set the temperature to 110°C, and the reaction time reaches 2.5 hours. After measuring the pH value of the solution is 2.21, the reaction is complete; and the reaction vessel is taken out from the oven, cooled to room temperature naturally, The obtained transparent and clear solution is the reactant gluconolactone.

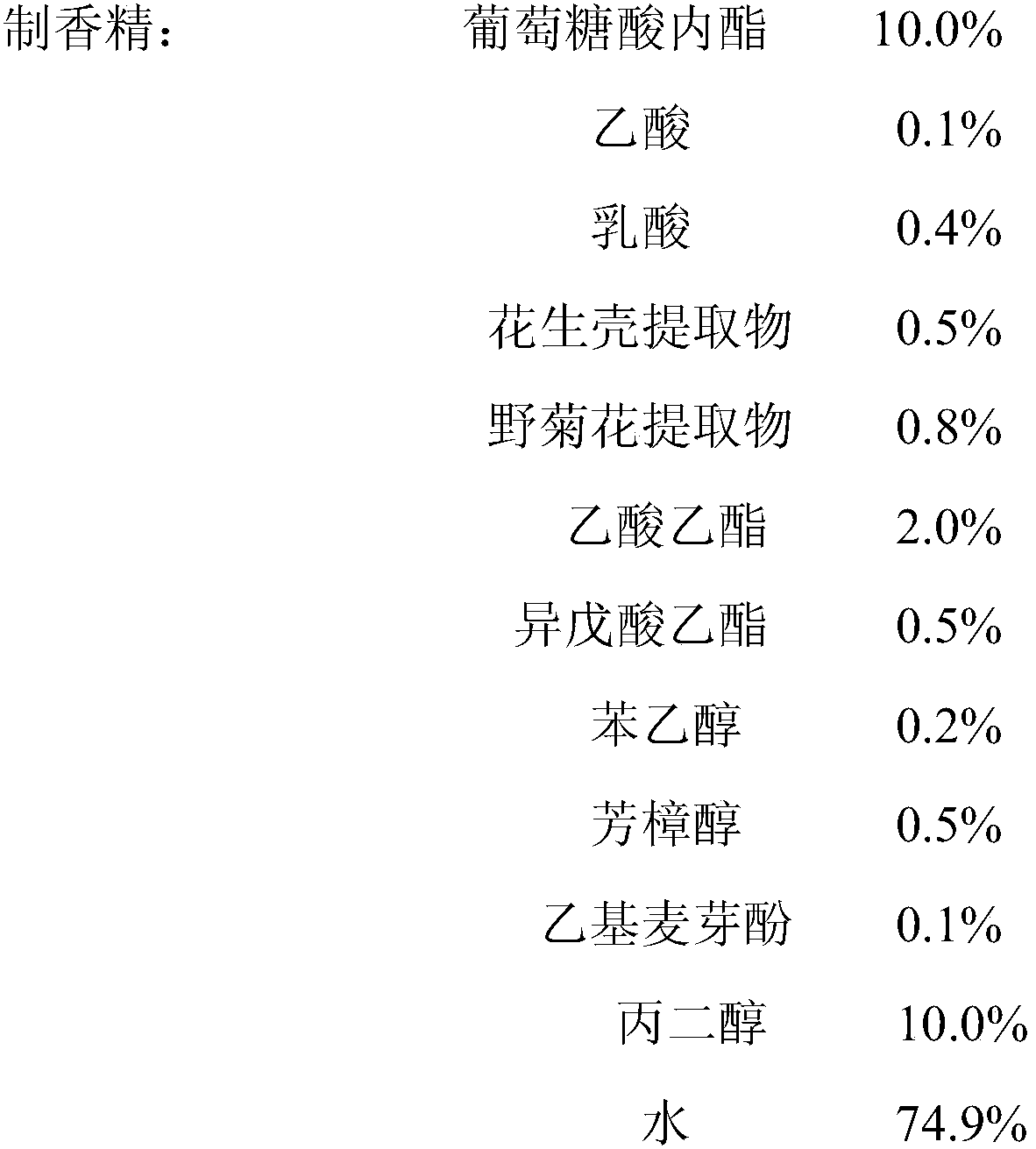

[0029] Adopt the gluconolactone prepared in embodiment 2 according to the following formula of mass percentage

[0030]

[0031] First, take half of ...

Embodiment 3

[0032] Embodiment 3, the preparation method of described a kind of gluconolactone is characterized in that concrete steps are as follows:

[0033] (1) Prepare glucose, water and 30% hydrogen peroxide solution according to the mass ratio of 5.5:3.5:1, first add all the glucose into the Erlenmeyer flask, then add water, then add 30% hydrogen peroxide The solution constitutes the reaction solution, and the frosted stopper is tightly covered;

[0034] (2) Place the Erlenmeyer flask in an oven, set the temperature to 90°C, and the reaction time reaches 3 hours. After measuring the pH value of the solution is 2.52, the reaction is complete; and the reaction vessel is taken out from the oven, cooled to room temperature naturally, The obtained transparent and clear solution is the reactant gluconolactone.

[0035] Adopt the gluconolactone prepared in embodiment 3 according to the following formula of mass percentage

[0036]

[0037] First, take half of the water in the above for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com