B0 bogie for power-centralized D-series high-speed train

A technology of concentrated power and EMUs, which is applied in the field of rail transit, can solve the problems of low wheel-rail action force requirements, low adhesion utilization, poor dynamic performance, etc., and achieve reduced axle load transfer, excellent comfort, and dynamics. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

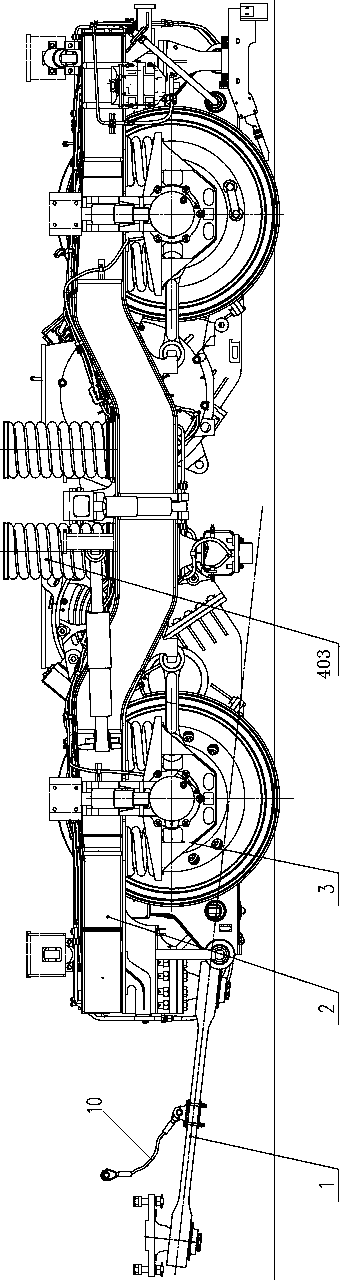

[0035] like Figure 1~4 As shown, a B0 bogie for a concentrated power EMU includes a sun-shaped frame 2, a wheel set 3, and a single drawbar 1.

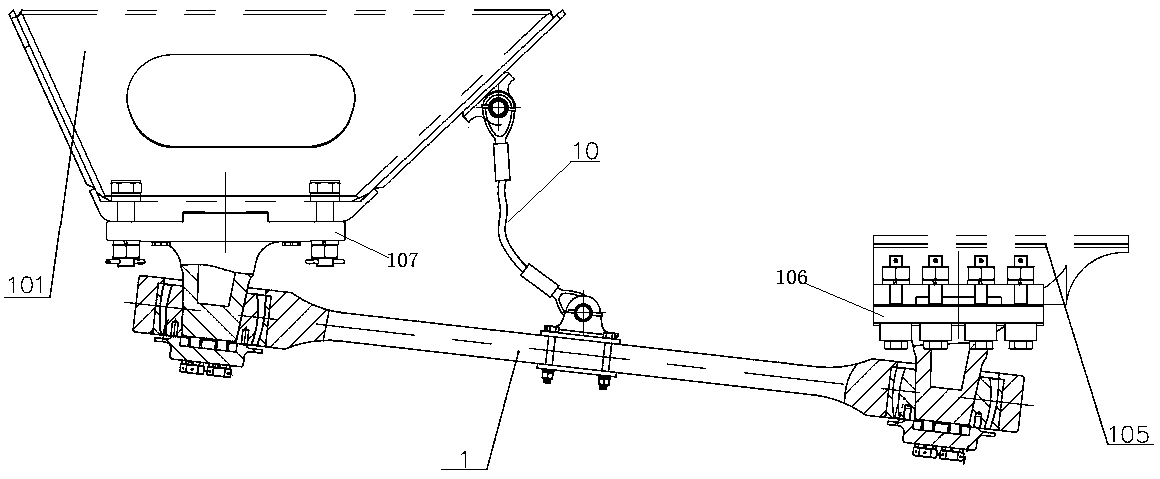

[0036] The end beam of the frame 2 is provided with a frame fifth wheel 105, one end of the single draw bar 1 is connected to the frame fifth wheel 105 through the first fifth wheel 106, and the other end is connected to the vehicle body chassis 101 through the second fifth wheel 107. superior. The height of the end of the single drawbar 1 connected to the frame fifth wheel 105 is lower than the height of the end connected to the vehicle body chassis 101 .

[0037] The wheel diameter of the wheel set 3 is 1050mm, and the intersection point A (namely the nominal traction point) of the extension line of the axis of the single drawbar 1 and the center line of the frame is 60mm from the rail surface.

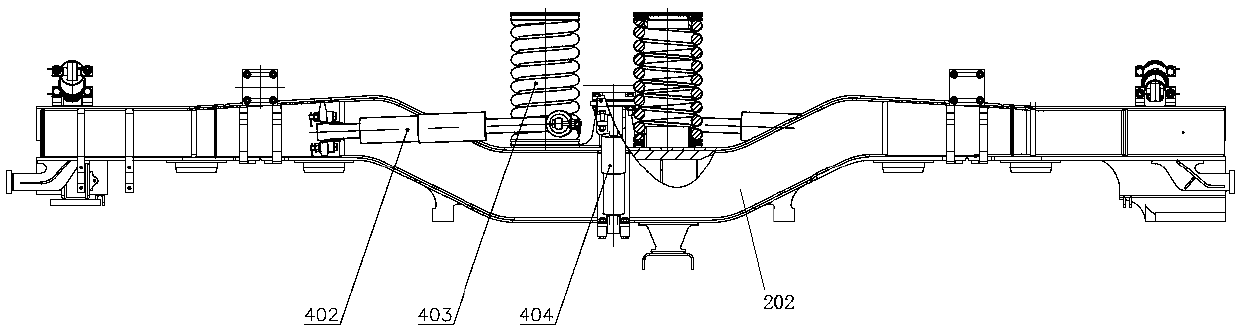

[0038] It also includes secondary springs 403 arranged on the frame side beams 202, two secondary springs 403 are arranged at intervals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com