Alloy aluminum plate locking apparatus for pre-coated laminating machine

A technology of alloy aluminum plate and laminating machine, which is applied to printing machines, general parts of printing machinery, printing, etc. It can solve the problems of no locking function, unstable installation, inconvenient locking of alloy aluminum plates, etc., and achieves convenience Coating operation, convenient and flexible movement and adjustment, and firm positioning and locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0013] The technical scheme of concrete implementation of the present invention is:

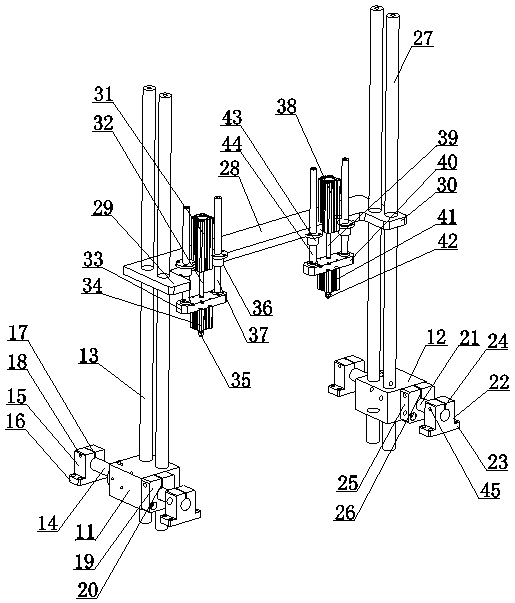

[0014] Such as figure 1 As shown, an alloy aluminum plate locking device for a pre-coating laminating machine includes a first horizontal slide 11 and a second horizontal slide 12; the first horizontal slide 11 is provided with a pair of first vertical guides Axis 13, the first horizontal guide shaft 14 is plugged into the side position of the first horizontal sliding seat 11, the two ends of the first horizontal guide shaft 14 are all provided with the first fixed seat 15, the bottom of the first fixed seat 15 is provided with The first fixed block 16, the top of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com