Test device and method for cooker ignition control board

An ignition control and testing device technology, applied in program control, general control system, electrical testing/monitoring, etc., can solve problems such as troublesome and inconvenient detection, low detection efficiency, human misjudgment, etc. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The features of the present invention and other relevant features are described in further detail below through the embodiments, so as to facilitate the understanding of those skilled in the art:

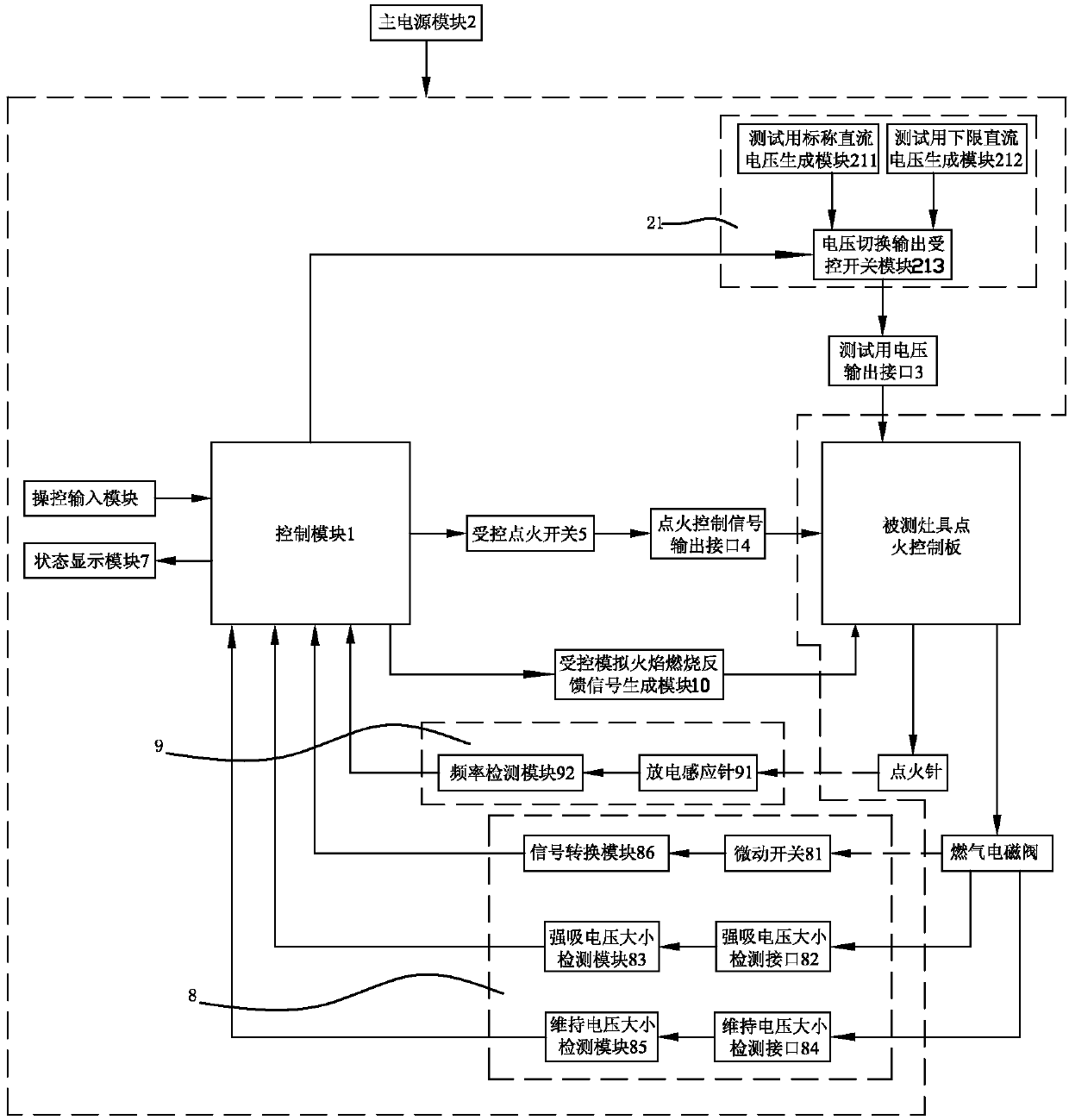

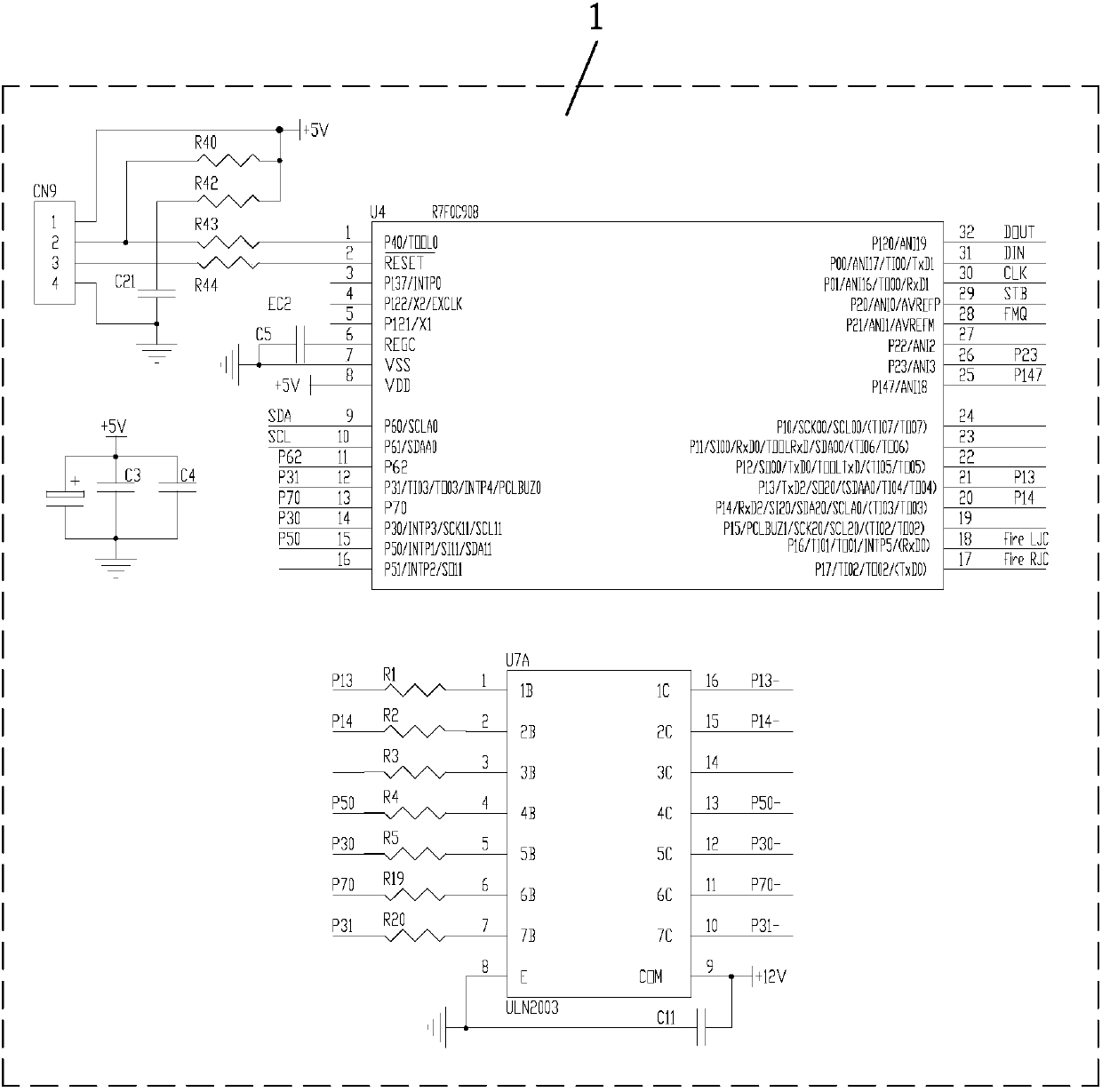

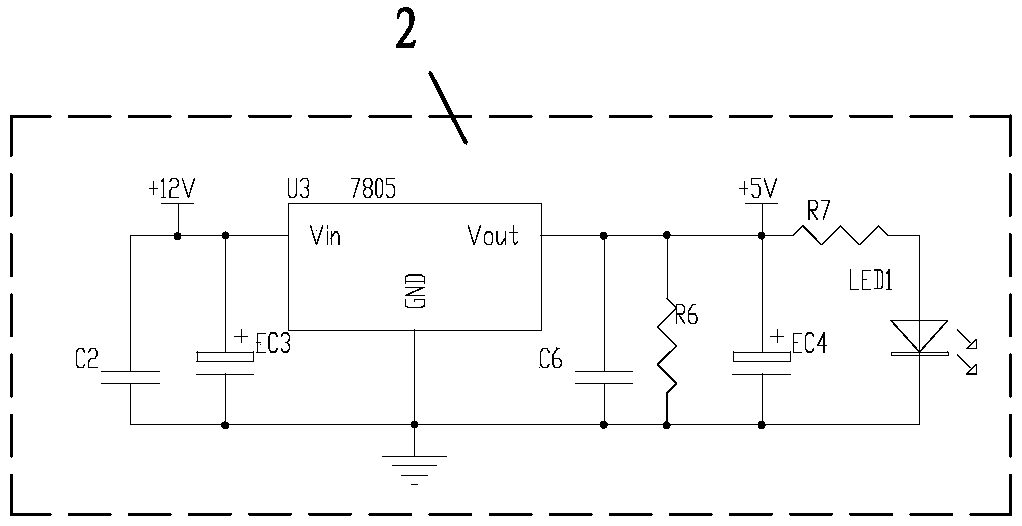

[0042] Such as figure 1 As shown, a test device for the ignition control board of the cooker includes a control module 1, a main power supply module 2 for the main power supply of the test device, and a test voltage for electrically connecting with the DC power input terminal of the ignition control board of the test cooker Output interface 3, an ignition control signal output interface 4 used to be electrically connected to the ignition control signal input end of the ignition control board of the cooking appliance under test, controlled by the control module 1 and used to output ignition control through the ignition control signal output interface 4 signal controlled ignition switch 5, the main power module 2 is connected with a test DC voltage generation module 21, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com