System for determining critical pressure gradient of foams generated at permeability mutation site

A technology of critical pressure and permeability, which is applied in the fields of permeability/surface area analysis, measuring device, suspension and porous material analysis, etc. It can solve problems such as not considering the influence of foam, and achieve the effect of improving calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

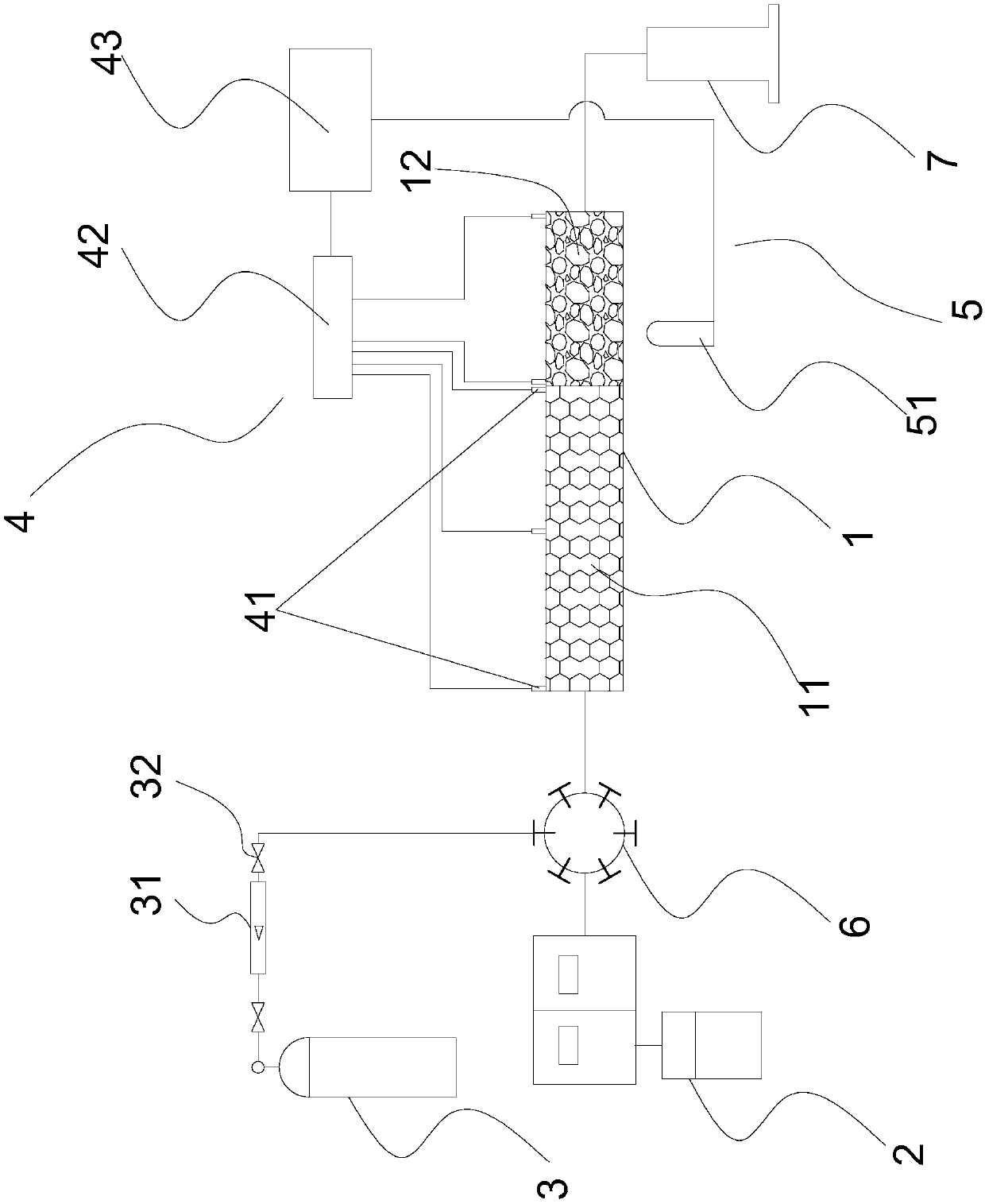

[0033] as attached figure 1 As shown, a system for measuring the critical pressure gradient of foam formation at sudden changes in permeability, including a sand filling pipe 1, a liquid supply device 2, a gas supply device 3, a data acquisition device 4 connected to the sand filling pipe, and an observation device 5, Among them, the sand filling pipe is provided with an injection end and an outflow end, and there are two sections of filling media with different particle sizes in the sand filling pipe. The medium is filled close to the outflow end to form the rear sand filling section 12, the front sand filling section is connected to the rear sand filling section, and the length ratio of the front sand filling section to the back sand filling section is 1:1 to 2:1, preferably 2:1 , the liquid supply device and the gas supply device are com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com