Detection method, device, system and storage medium for lighting of pipe gallery in motor car maintenance warehouse

A detection system and detection method technology, applied in the direction of measuring devices, machine/structural component testing, optical instrument testing, etc., can solve the problem of requiring manual inspection, and achieve the effect of reducing labor management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

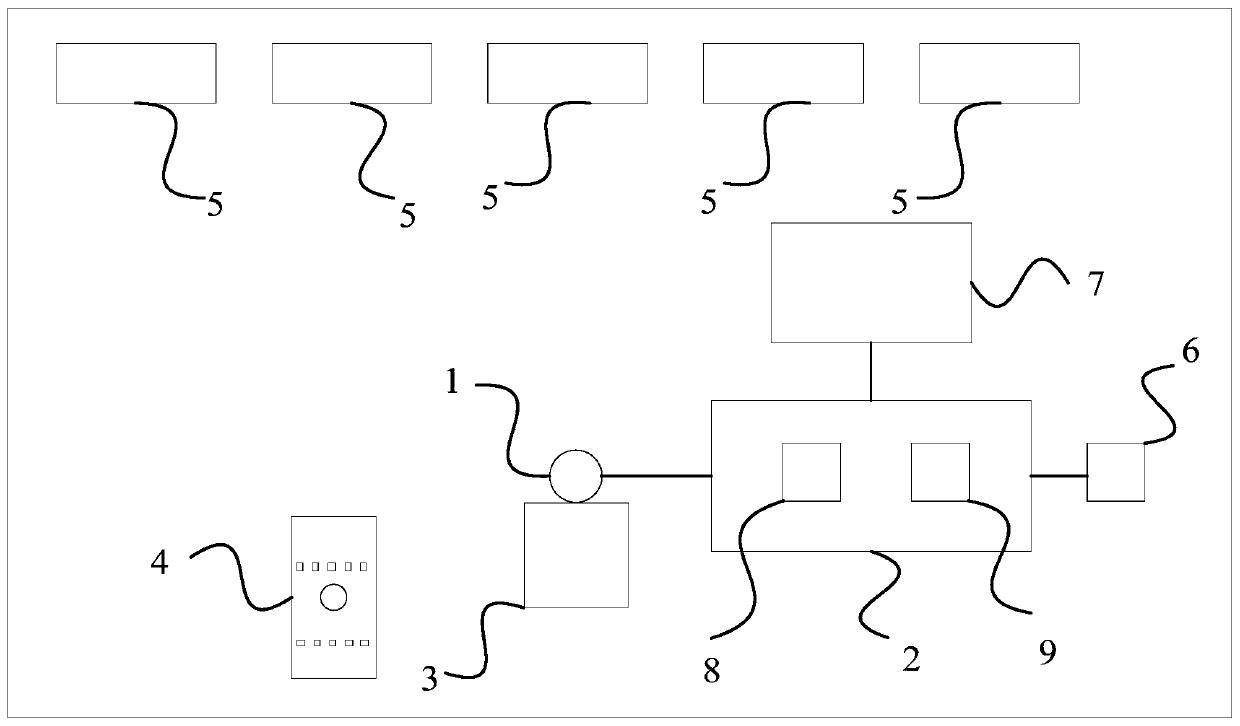

[0030] figure 1 It is a structural block diagram of a detection system for the lighting of the pipe gallery of the motor vehicle maintenance warehouse provided by Embodiment 1 of the present invention. The detection system includes a camera 1 , a detection terminal 2 , a mobile platform 3 , and an operating handle 4 .

[0031] Specifically, the camera 1 is set on the mobile platform 3 and is connected to the detection terminal 2 through a data line. The camera 1 is used to take pictures of the lighting images of n lighting lamps 5 on the pipe gallery of the maintenance warehouse, and send the lighting images to To the detection terminal 2, n≥1;

[0032] The operating handle 4 controls the movement of the mobile platform 3 , and the detection terminal 2 is used for judging the lighting state of the lighting lamp according to the image of the lighting lamp.

[0033] Specifically, the detection terminal 2 may include a processor 8 and a memory 9, the processor 8 is used to judge...

Embodiment 2

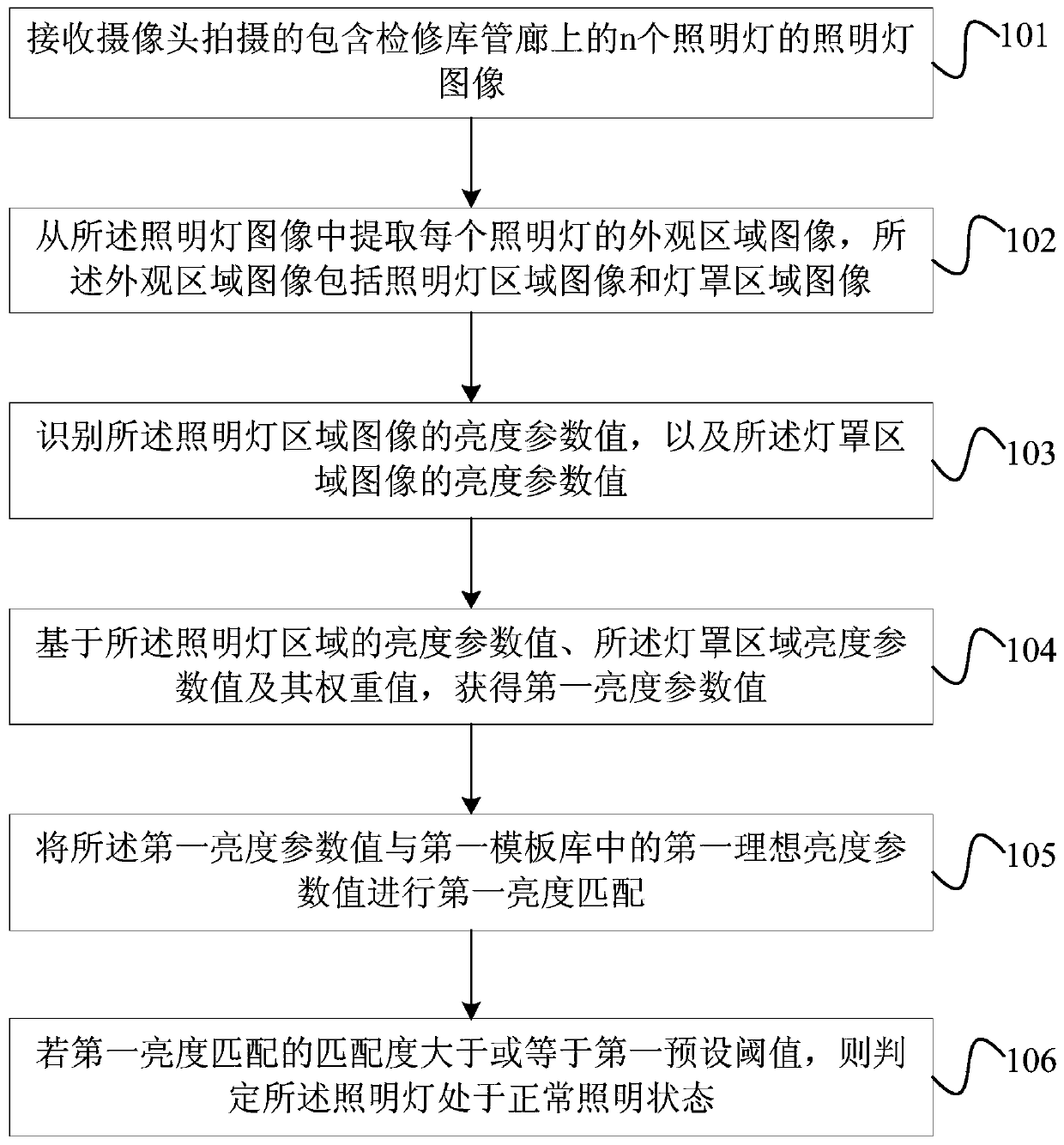

[0038] figure 2 It is a flow chart of a detection method for the lighting of the pipe corridor of the motor vehicle maintenance depot provided by Embodiment 2 of the present invention. The detection method provided by this embodiment can be applied to the detection system of Embodiment 1, and specifically includes the following steps:

[0039] Step 101, receiving the lighting image captured by the camera and including n lighting lights on the pipe corridor of the maintenance depot;

[0040] In the embodiment of the present invention, the detection system can be a movable detection platform. In the specific application process, technicians can manipulate the operating handle to move the detection system from the head to the tail of the maintenance warehouse pipe gallery, thereby completing the entire maintenance The detection process of the lighting conditions of the warehouse pipe gallery lighting. During the movement, the detection terminal of the detection system can receiv...

Embodiment 3

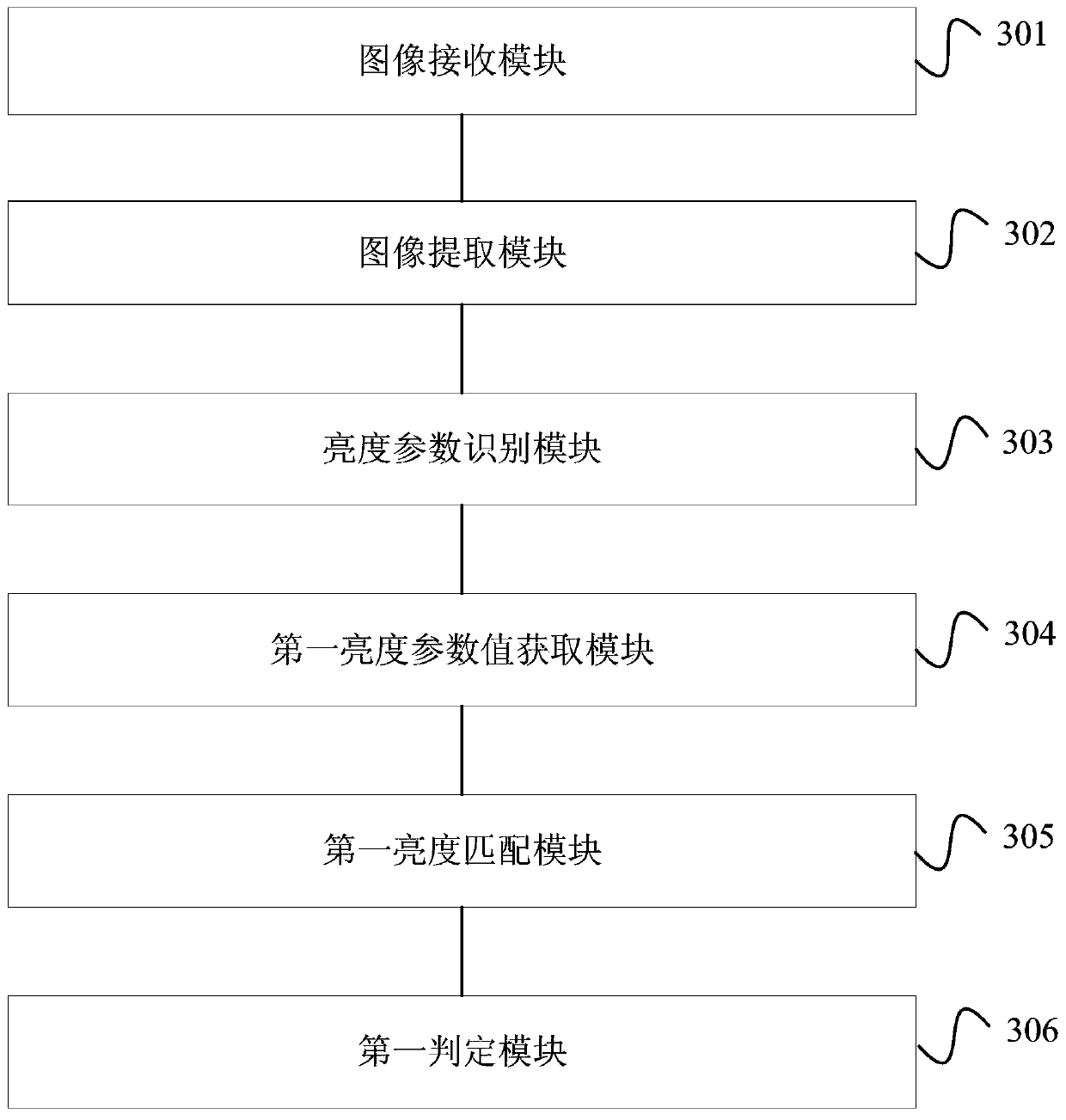

[0109] image 3 A structural block diagram of a detection device for the lighting of the pipe corridor of the motor vehicle maintenance warehouse provided by Embodiment 3 of the present invention. The detection device may include:

[0110] The image receiving module 301 is used to receive the light image captured by the camera and including n light lights on the pipe corridor of the maintenance warehouse, n≥1;

[0111] An image extraction module 302, configured to extract an appearance area image of each illuminating lamp from the illuminating lamp image, and the appearance area image includes an illuminating lamp area image and a lampshade area image;

[0112] A brightness parameter identification module 303, configured to identify the brightness parameter value of the lighting lamp area image and the brightness parameter value of the lampshade area image;

[0113] A first brightness parameter value acquisition module 304, configured to obtain a first brightness parameter va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com