Self-sealing spiral energy gathering joint cutting device

A self-sealing, spiral-shaped technology, applied in blasting and other directions, can solve the problems of drilling and blasting, difficult to change the size, complicated production, etc., and achieve good self-sealing, improved utilization rate, and large gap range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

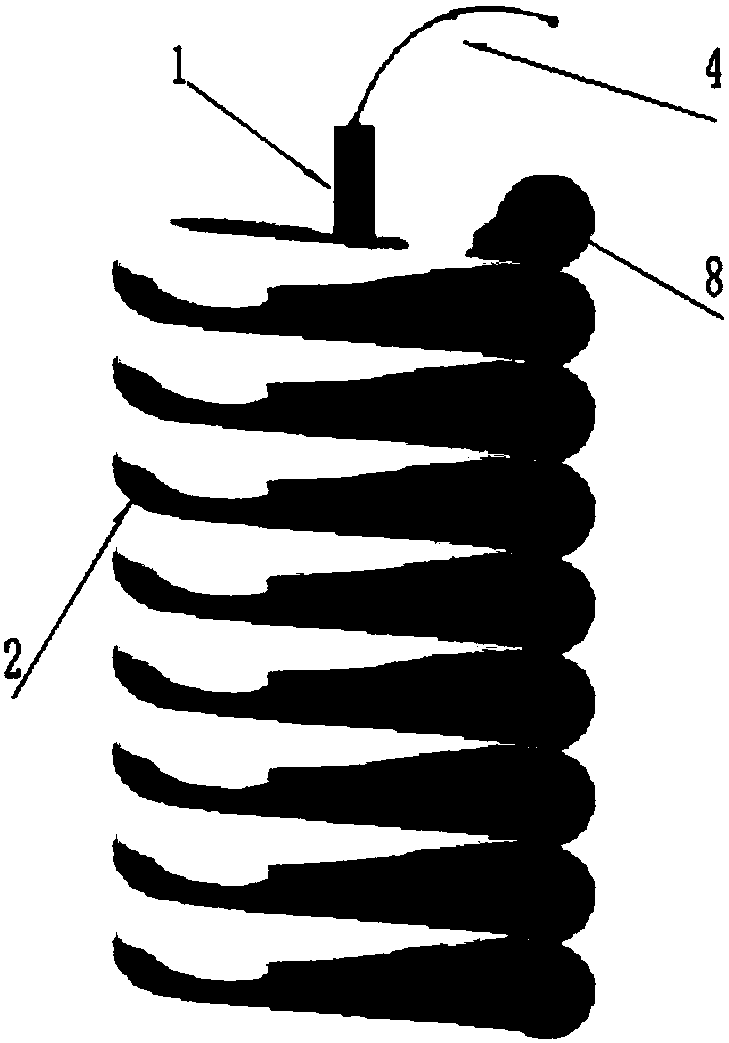

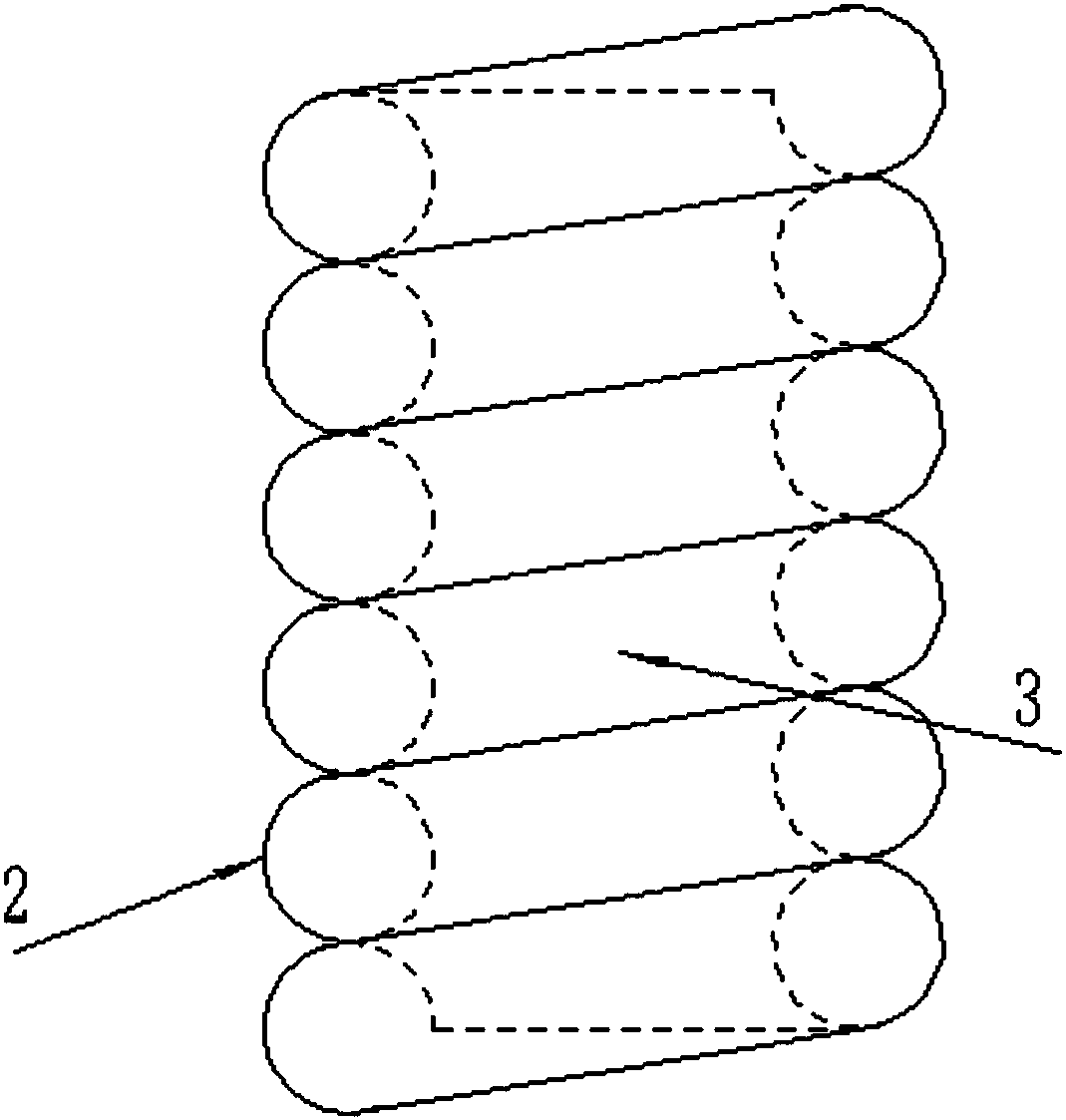

[0035] Example 1: A 10-turn spiral aluminum tube slitter penetrates the steel plate

[0036] refer to Figure 4 and Figure 5, The wall thickness of the spiral tube is 1.20mm, the outer diameter of the tube is 5.00mm, and the tube material is aluminum. The inner diameter of the processed spiral tubular drug-type cover is 21.00mm, and the height is 50mm. The explosives are 90% RDX and 10% ammonium nitrate. After mixing evenly, fill the explosives into the spiral tubular drug cover and compact them. The density is guaranteed to be 1.5g / cm 3 to 1.7g / cm 3 . Since there is no bonding between the tubes of the spiral tube, the explosives will be squeezed out after the powder is pressed, so it should be cleaned up when the explosives are found to be squeezed out. The experiment uses a non-priming detonator 1 to detonate, and the detonator 1 is placed in the center of the surface at one end of the shaped charge.

[0037] The steel plate 5 penetration test was carried out on the sh...

Embodiment 2

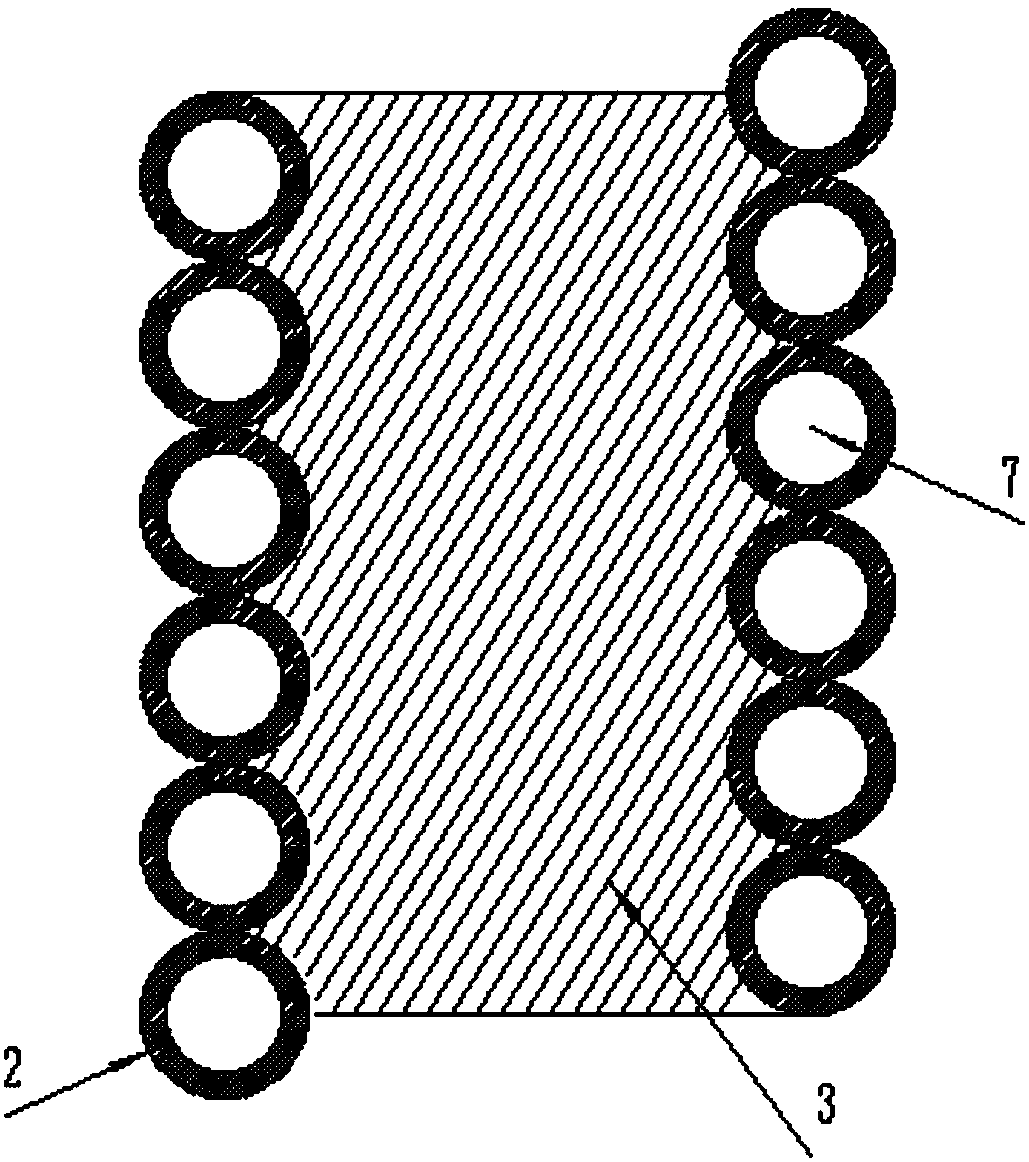

[0038] Example 2: A 3-turn helical aluminum tube slitter penetrates a round tube

[0039] refer to figure 2 and Figure 6 , The wall thickness of the spiral tube is 1.30mm, the outer diameter of the tube is 6.00mm, and the tube material is aluminum. The inner diameter of the processed spiral tubular drug-type cover is 18.00mm, and the height is 18mm. The explosives are 90% RDX and 10% ammonium nitrate. After mixing evenly, fill the explosives into the spiral tubular drug cover and compact them. The density is guaranteed to be 1.5g / cm 3 to 1.7g / cm 3 . Since there is no bonding between the tubes of the spiral tube, the explosives will be squeezed out after the powder is pressed, so it should be cleaned up when the explosives are found to be squeezed out. The experiment uses a non-priming detonator 1 to detonate, and the detonator 1 is placed in the center of the surface at one end of the shaped charge.

[0040] A steel pipe penetration test was carried out on the shaped ch...

Embodiment 3

[0041] Example 3: A 4-turn spiral aluminum tube slitter penetrates the steel plate

[0042] refer to Figure 4 and Figure 5 , The wall thickness of the spiral tube is 1.60mm, the outer diameter of the tube is 8.00mm, and the tube material is aluminum. The inner diameter of the processed spiral tubular medicine cover is 25.00mm, and the height is 32mm. The explosives are 90% RDX and 10% TNT. After mixing evenly, fill the explosives into the spiral tubular drug-shaped cover and compact them. The density is guaranteed to be 1.5g / cm 3 to 1.7g / cm 3 . Since there is no bonding between the tubes of the spiral tube, the explosives will be squeezed out after the powder is pressed, so it should be cleaned up when the explosives are found to be squeezed out. The experiment uses a non-priming detonator 1 to detonate, and the detonator 1 is placed in the center of the surface at one end of the shaped charge.

[0043] The steel plate 5 penetration test was carried out on the shaped ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com